A polyacrylamide microsphere, a nanoemulsion for regulating and flooding low-permeability reservoirs, its preparation method and application

A nano-emulsion and acrylamide technology, applied in the field of polymer emulsion, can solve the problems of inability to plug the pores of the target formation, large cross-linked polymer particle size, and low degree of recovery, so as to increase the swept volume of injected water, Small particle size and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

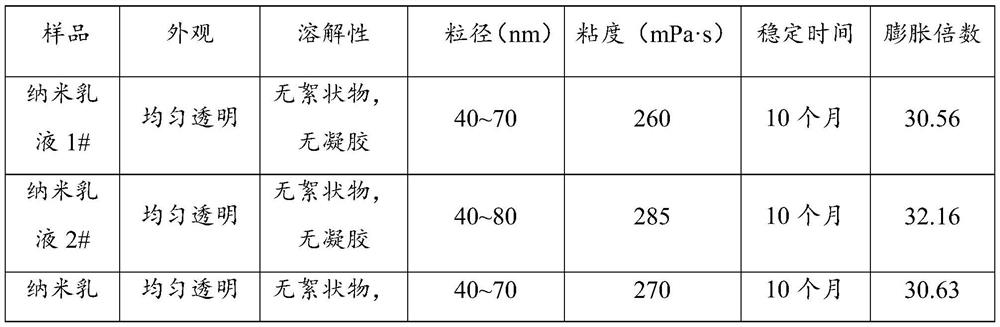

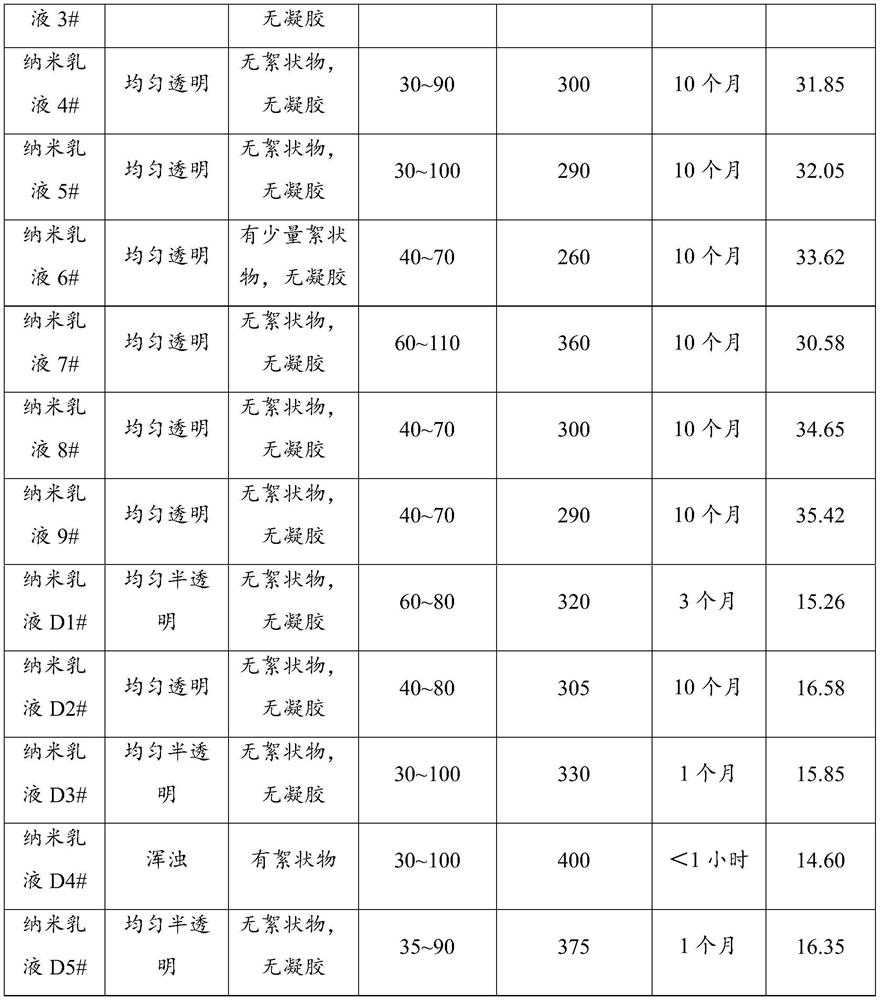

[0038] Example 1 Nanoemulsion 1#

[0039] Nanoemulsion 1# contains the following raw material components by mass: 20 parts of acrylamide monomer, 2 parts of 2-acrylamide-2-methylpropanesulfonic acid, 0.1 part of N,N-methylenebisacrylamide, water loss 23 parts of sorbitan fatty acid ester S-60, 12 parts of polyoxyethylene sorbitan fatty acid ester T-80, 3 parts of nonylphenol polyoxyethylene ether Tx-10, 5 parts of sodium alkyl benzene sulfonate, initiator 0.765 parts of ethylenediaminetetraacetic acid tetrasodium, 80 parts of white oil and 25 parts of deionized water, wherein the initiator is composed of azobisisobutyronitrile, sodium bisulfite and potassium persulfate, azobisisobutyronitrile The mass ratio of nitrile, sodium bisulfite and potassium persulfate was 4.5:3.5:2.

[0040] The preparation method of nanoemulsion 1# comprises the following steps:

[0041] (1) Preparation of aqueous solution

[0042] Add 250Kg of deionized water to the clean stainless steel reactor,...

Embodiment 2

[0050] Example 2 Nanoemulsion 2#

[0051] The preparation process of nanoemulsion 2# is the same as that of Example 1, except that in step (1), 250Kg of deionized water is added to the clean stainless steel reaction kettle, the stirring is started, the stirring speed is controlled to 75r / min, 250Kg of acrylamide monomer is added, and the stirring is carried out. 10min, add 20Kg 2-acrylamide-2-methylpropanesulfonic acid, stir for 5min, add KOH to adjust pH to neutral, add 3Kg N,N-methylenebisacrylamide, stir for 5min, then add 1Kg ethylenediaminetetramine Tetrasodium acetate was stirred for 10min to obtain an aqueous solution.

Embodiment 3

[0052] Example 3 Nanoemulsion 3#

[0053] The preparation process of nanoemulsion 3# is the same as that of Example 1, except that in step (1), 250Kg of deionized water is added to the clean stainless steel reaction kettle, the stirring is started, the stirring speed is controlled to 75r / min, 150Kg of acrylamide monomer is added, and the stirring is carried out. 10min, add 10Kg 2-acrylamide-2-methylpropanesulfonic acid, stir for 5min, add KOH to adjust pH to neutrality, add 2Kg N,N-methylenebisacrylamide, stir for 5min, then add 5Kg ethylenediaminetetramine Tetrasodium acetate was stirred for 10min to obtain an aqueous solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com