A functional desmosome plugging agent and its preparation method and application

A technology of plugging agent and desmosome, which is applied in the direction of chemical instruments and methods, earth drilling, mining fluids, etc. It can solve the problems of easy plugging of low-permeability layers, poor temperature resistance, salt resistance, and limited application, so as to achieve convenient construction , high tensile strength and low shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a method for preparing functional desmoplastic plugging agent particles, wherein the method includes the following steps:

[0040] a. Sieving to obtain 40 mesh quartz sand;

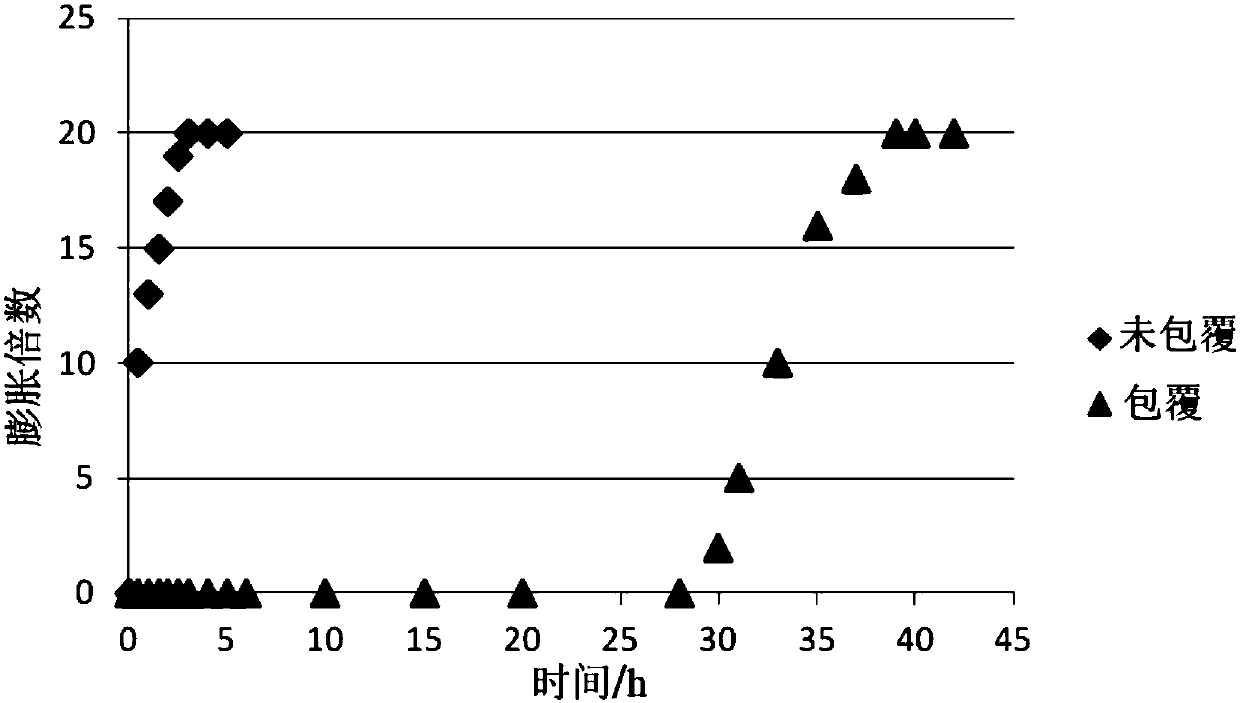

[0041] b. After the acrylic resin is melted and treated in a fluidized bed, the surface of the core material (quartz sand) is coated with acrylic resin, and after the thickness reaches 15 μm, it is dried and sieved;

[0042] c. The linear low-density polyethylene is melted and treated in a fluidized bed, the surface of the particles obtained in step b is coated with linear low-density polyethylene, and after the thickness reaches 10 μm, after drying and sieving, the functional bridge particles are obtained. 剂粒。 Agent particles.

Embodiment 2

[0044] This embodiment provides a method for preparing a functional desmosome plugging control agent, wherein the method specifically includes the following steps:

[0045] Add 2 g of guar gum to 200 mL of water, stir for 60 minutes, and then add 10 g of the functional desmoplastic plugging agent particles prepared in Example 1, and stir for 100 minutes to obtain the functional desmoplastic plugging agent.

Embodiment 3

[0047] This embodiment provides a method for preparing functional desmoplastic plugging agent particles, wherein the method includes the following steps:

[0048] a. Sieving to obtain 100 mesh ceramsite;

[0049] b. After the super absorbent resin is melted and treated in a fluidized bed, the surface of the core material (ceramsite) is coated with super absorbent resin, and after the thickness reaches 6 μm, it is dried and sieved;

[0050] c. After the phenolic resin is melted and treated in a fluidized bed, the surface of the particles obtained in step b is coated with the phenolic resin to a thickness of 5 μm, dried and sieved to obtain functional bridge particle plugging control agent particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com