Preparation method of photocatalytic hydrogel particles

A hydrogel and photocatalytic technology, applied in the field of photocatalytic materials, can solve problems such as difficult recycling, achieve low cost, realize recycling, and easy separation and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing photocatalytic hydrogel particles, comprising the following preparation steps:

[0022] S1. Dissolve 4g of nano-titanium dioxide, 1g of graphene oxide and 0.5g of amino polyethylene glycol acrylate in 200mL of water, ultrasonically disperse for 30min, at 40 o C was reacted for 6 hours, left standing and filtered to obtain a graphene oxide composite;

[0023] S2. In the reactor, add 10 g of acrylamide, 0.2 g of N,N-methylenebisacrylamide, 0.01 g of potassium persulfate, 0.1 g of graphene oxide complex and 5 g of deionized water, Mix uniformly under the action of ultrasound to obtain a reaction solution;

[0024] S3, using a syringe to drop the reaction solution into a 25cm long heatable glass tube filled with soybean oil at a rate of every 60s, the temperature of the soybean oil is 80 o C, the product collected at the lower end of the glass tube was washed with water to obtain photocatalytic hydrogel particles.

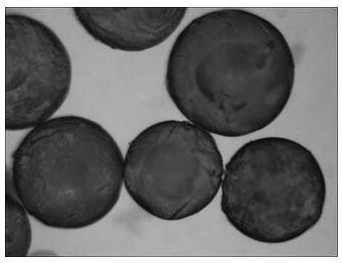

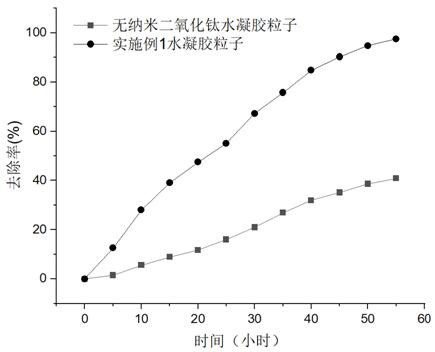

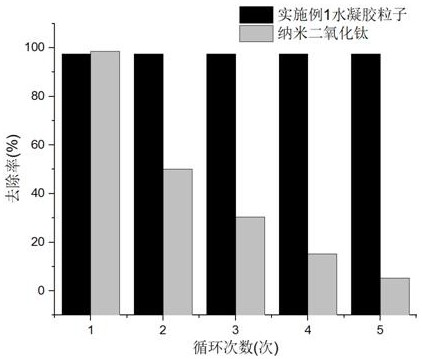

[0025] The morphology of the pho...

Embodiment 2

[0027] A method for preparing photocatalytic hydrogel particles, comprising the following preparation steps:

[0028] S1. Dissolve 1g of nano-titanium dioxide, 4g of graphene oxide and 8g of aminopolyethylene glycol acrylate in 750mL of water, ultrasonically disperse for 30min, at 40 o C was reacted for 6 hours, left standing and filtered to obtain a graphene oxide composite;

[0029] S2. In the reactor, add 10 g of acrylamide, 2 g of N,N-methylenebisacrylamide, 0.01 g of ammonium persulfate, 1 g of graphene oxide complex and 20 g of deionized water, and Under action, mix uniformly to obtain reaction solution;

[0030] S3. Use a syringe to drop the reaction solution into a 50cm long heatable glass tube filled with soybean oil at a rate of every 30s. The temperature of the soybean oil is 95 o C, the product collected at the lower end of the glass tube was washed with water to obtain photocatalytic hydrogel particles.

Embodiment 3

[0032] A method for preparing photocatalytic hydrogel particles, comprising the following preparation steps:

[0033] S1. Dissolve 2g of nano-titanium dioxide, 2g of graphene oxide and 2g of aminopolyethylene glycol acrylate in 500mL of water, ultrasonically disperse for 30min, and dissolve at 40 o C was reacted for 6 hours, left standing and filtered to obtain a graphene oxide composite;

[0034] S2. In the reactor, add 10 g of acrylamide, 0.5 g of N,N-methylenebisacrylamide, 0.02 g of V40, 0.5 g of graphene oxide composite and 15 g of deionized water, and Under action, mix uniformly to obtain reaction solution;

[0035] S3. Use a syringe to drop the reaction liquid into a 30cm long heatable glass tube filled with soybean oil at a rate of every 40s. The temperature of the soybean oil is 90 o C, the product collected at the lower end of the glass tube was washed with water to obtain photocatalytic hydrogel particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com