Method for blending apple wine by fermenting concentrated apple juice

A technology for concentrating apple juice and cider, which is applied in the field of fruit wine beverages, can solve the problems of limited production period, high enterprise cost, large equipment investment, etc., and achieves the effect of avoiding wine body loss, low cost and less equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

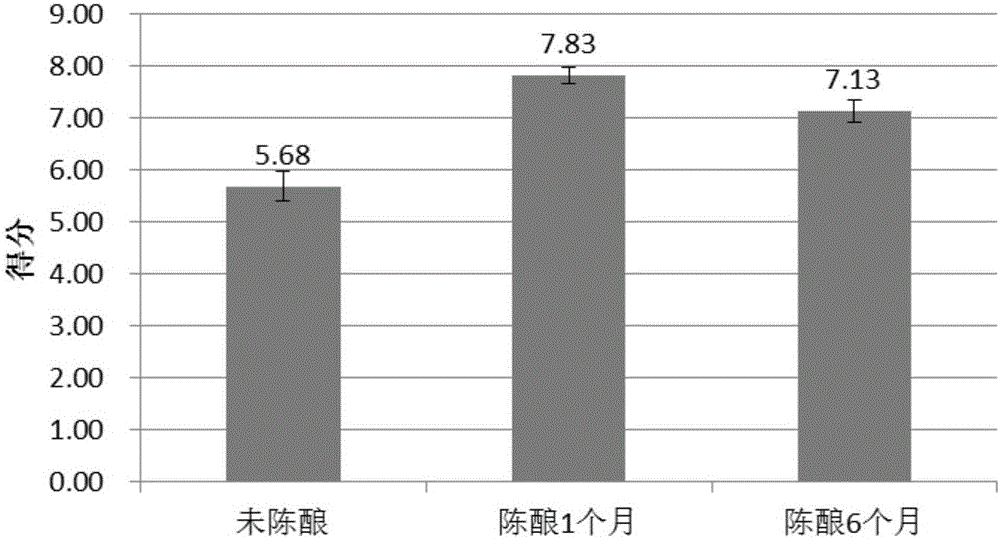

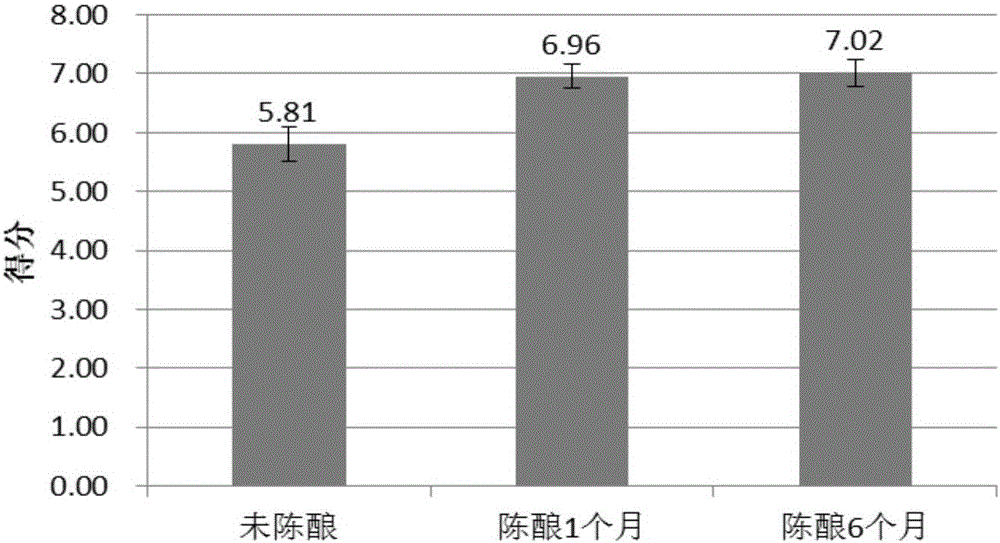

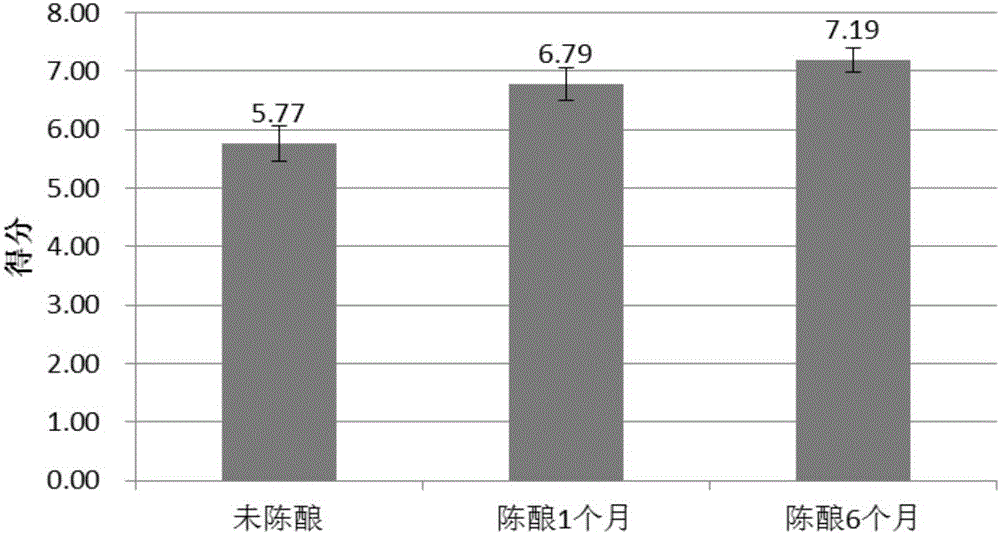

Image

Examples

Embodiment 1

[0030] A method for fermenting concentrated apple juice to deploy cider, specifically comprising the following steps:

[0031] 1) Dilution: using the concentrated apple juice as raw material, dilute the concentrated apple clear juice with a sugar content of 70Brix and an acidity of 1.44% (in terms of malic acid) to a sugar content of 20Brix and an acidity of 0.404%.

[0032] 2) Bacteriostasis: Add potassium metabisulfite to the apple juice diluted in step 1) and let it stand for 2 hours to inhibit the growth of miscellaneous bacteria. Among them, 50mg of potassium metabisulfite is added to every 1L of apple juice;

[0033] 3) Fermentation: Add the activated active dry yeast into the clear apple juice, control the fermentation temperature at 20° C., and ferment for 10 days until the sugar content does not change to obtain wine liquor. Among them, the quality of active dry yeast added to every 1L of apple juice is 250mg;

[0034] Among them, the activated active dry yeast is o...

Embodiment 2

[0044] A method for preparing cider from concentrated apple juice, specifically comprising the following steps:

[0045] 1) Dilution: using concentrated apple juice as raw material, the concentrated apple clear juice with a sugar content of 70Brix and an acidity of 1.44% (in terms of malic acid) is diluted to a sugar content of 20Brix and an acidity of 0.404%.

[0046] 2) Bacteriostasis: Add potassium metabisulfite to the apple juice diluted in step 1) and let it stand for 2 hours to inhibit the growth of miscellaneous bacteria. Among them, 50mg of potassium metabisulfite is added to every 1L of apple juice;

[0047] 3) Fermentation: Add the activated active dry yeast into the clear apple juice, control the fermentation temperature at 20° C., and ferment for 10 days until the sugar content does not change to obtain wine liquid. Among them, the quality of active dry yeast added to every 1L of apple juice is 250mg;

[0048] Among them, the activated active dry yeast is obtaine...

Embodiment 3

[0058] A method for preparing cider from concentrated apple juice, specifically comprising the following steps:

[0059] 1) Dilution: using concentrated apple juice as raw material, the concentrated apple clear juice with a sugar content of 70Brix and an acidity of 1.44% (in terms of malic acid) is diluted to a sugar content of 20Brix and an acidity of 0.404%.

[0060] 2) Bacteriostasis: Add potassium metabisulfite to the apple juice diluted in step 1) and let it stand for 2 hours to inhibit the growth of miscellaneous bacteria. Among them, 50mg of potassium metabisulfite is added to every 1L of apple juice;

[0061] 3) Fermentation: Add the activated active dry yeast into the clear apple juice, control the fermentation temperature at 20° C., and ferment for 10 days until the sugar content does not change to obtain wine liquid. Among them, the quality of active dry yeast added to every 1L of apple juice is 250mg;

[0062] Among them, the activated active dry yeast is obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com