A permanent magnet rail

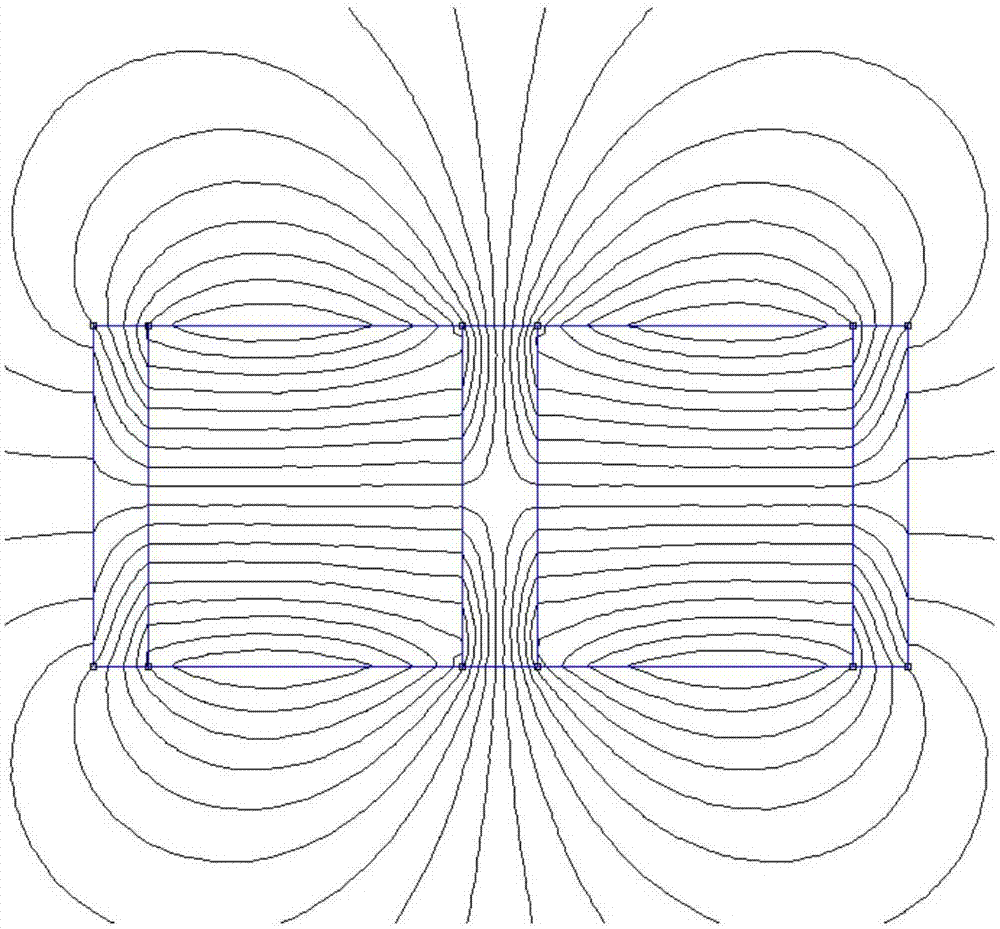

A technology of guide rails and permanent magnets, applied in tracks, roads, buildings, etc., can solve problems such as inability to form a closed magnetic circuit, incomplete magnetic-gathering structure, and poor magnetic-gathering effect, so as to ensure high-speed operation performance and improve the magnetic-gathering effect , the effect of suppressing the unevenness of the magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

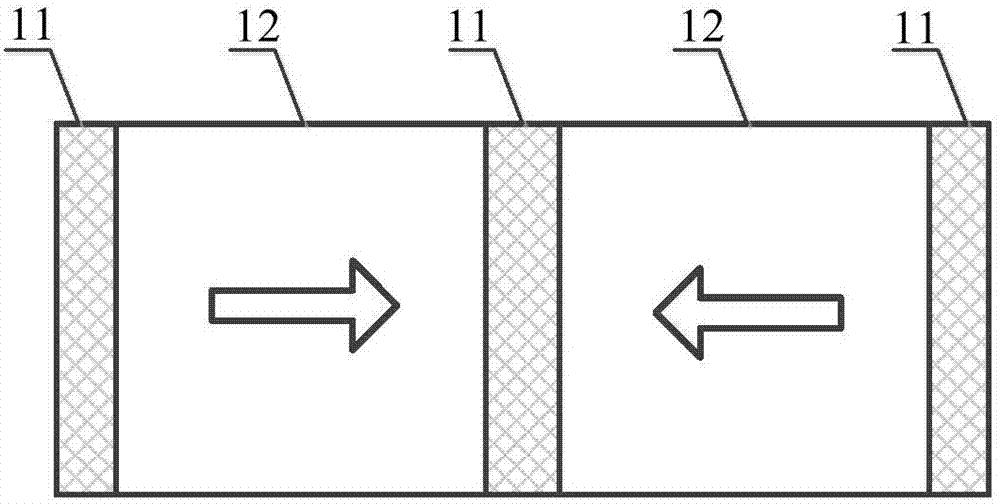

[0064] Embodiment 1. The permanent magnet guide rail is composed of 5 permanent magnets (ie magnetized magnets), including 3 horizontal magnetized magnets and 2 vertical magnetized magnets.

[0065] Figure 7 It is a schematic cross-sectional view of the permanent magnet guide rail in Embodiment 1 of the present invention. like Figure 7 As shown, in the permanent magnet guide rail in the first embodiment, N is 5, that is, the total number of the horizontal magnetization magnets and the vertical magnetization magnets is 5 pieces.

[0066] For example, if Figure 7 As shown, the permanent magnet guide rail is composed of 5 pieces of magnetized magnets 71-75 and 2 pieces of carbon steel 76 and 77. Among them, 71, 73 and 75 are horizontal magnetization magnets, 72 and 74 are vertical magnetization magnets, the horizontal magnetization magnets and the vertical magnetization magnets are arranged at intervals, and carbon steel 76 and 77 are arranged on the vertical magnetization ...

Embodiment 2

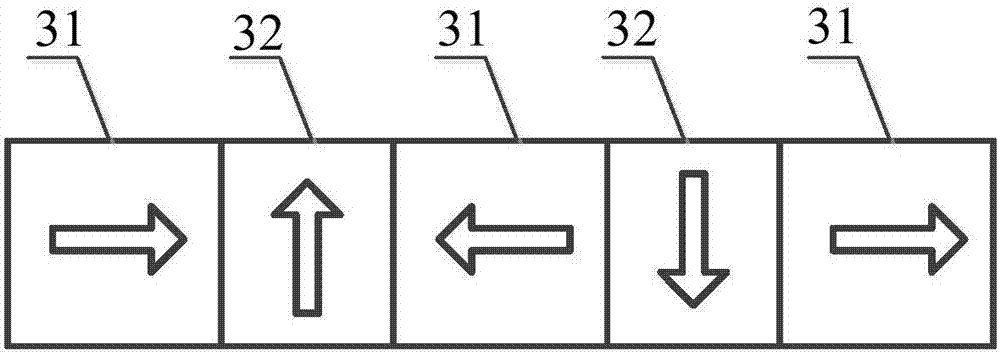

[0072] Embodiment 2. The permanent magnet guide rail is composed of 5 permanent magnets (ie magnetized magnets), including 2 horizontal magnetized magnets and 3 vertical magnetized magnets.

[0073] Figure 9 It is a schematic cross-sectional view of the permanent magnet guide rail in the second embodiment of the present invention. like Figure 9 As shown, in the permanent magnet guide rail in the second specific embodiment, N is 5, that is, the total number of the horizontal magnetization magnets and the vertical magnetization magnets is 5 pieces.

[0074] For example, if Figure 9 As shown, the permanent magnet guide rail is composed of 5 pieces of magnetized magnets 91-95 and 3 pieces of carbon steel 96, 97 and 98. Among them, 91, 93 and 95 are vertical magnetization magnets, 92 and 94 are horizontal magnetization magnets, the horizontal magnetization magnets and vertical magnetization magnets are arranged at intervals, and carbon steel 96, 97 and 98 are arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com