Environment-friendly and energy-saving integrated cast-in-situ lightweight concrete wall and construction method thereof

A lightweight concrete and construction method technology, applied in walls, building components, buildings, etc., can solve the problems of weak bonding, restricting the development of cast-in-place lightweight concrete walls, affecting the strength of walls and hanging force, etc. Achieve convenient construction, good economic and social benefits, and reduce project management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

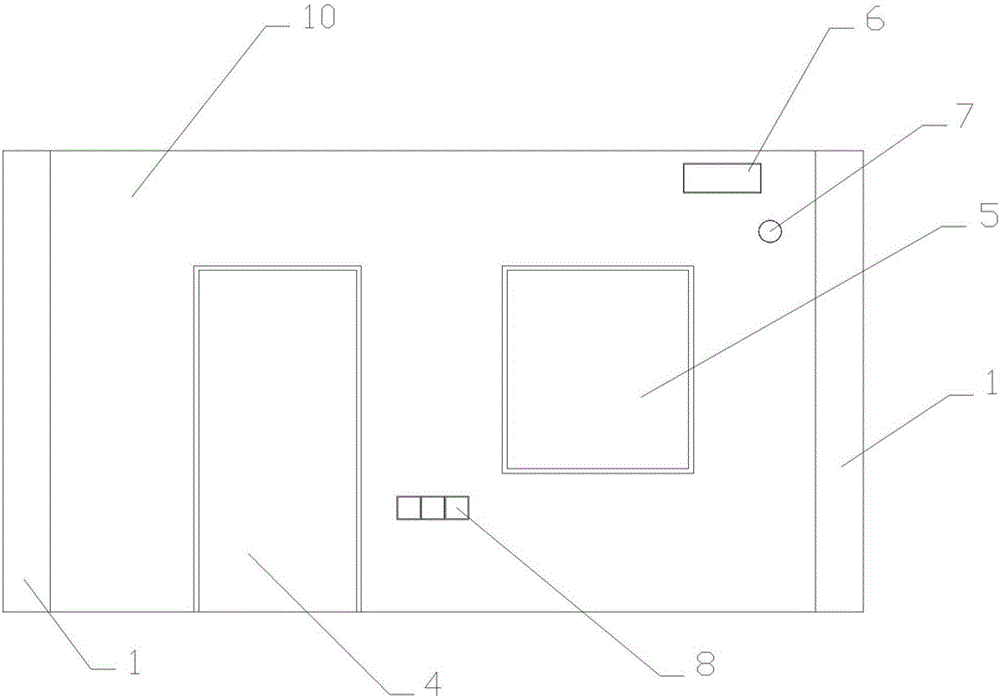

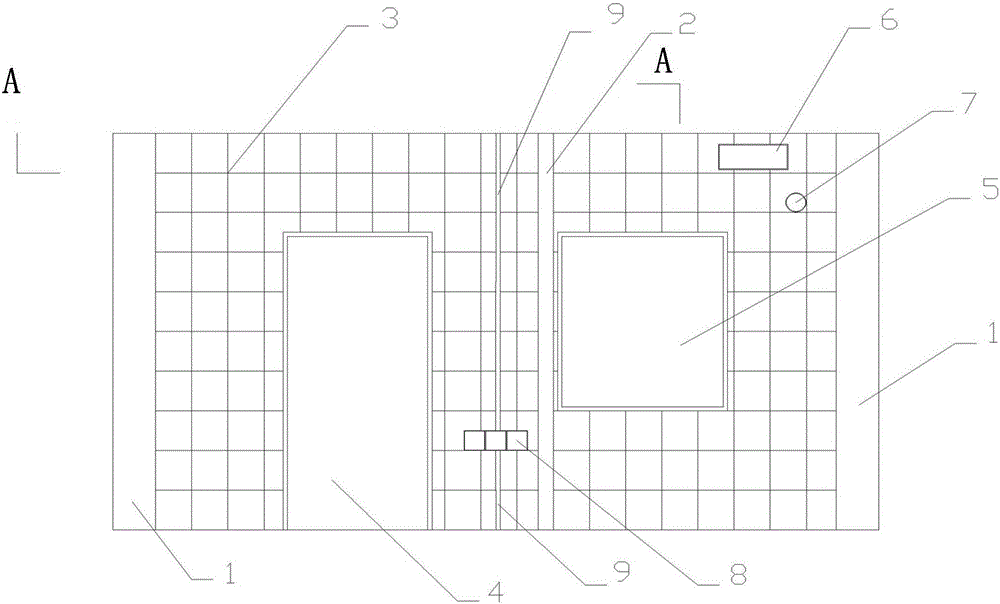

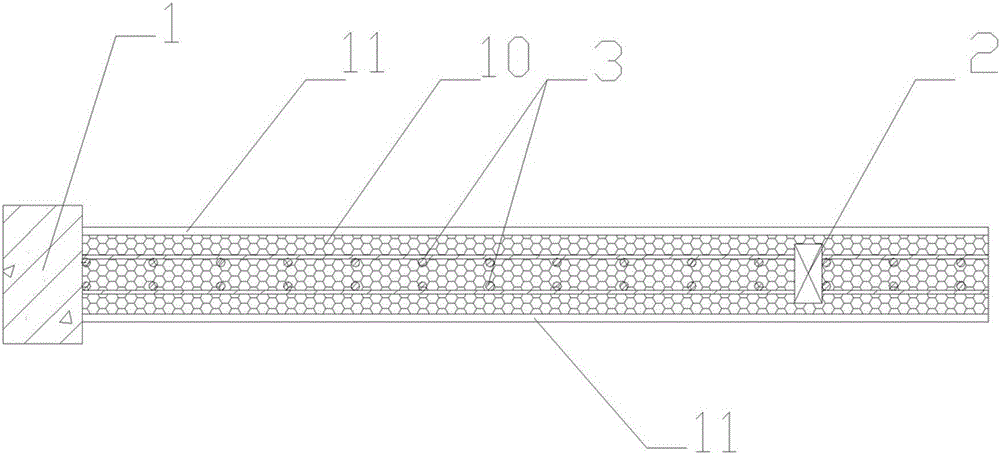

[0034] Such as Figure 1~3 As shown, it is a green energy-saving integrated cast-in-place lightweight concrete wall of the present invention, including a wall body 10 made of formwork cast-in-place lightweight concrete, steel mesh 3, structural columns 2 and tie bars (in the figure not shown), tie bars are located on the structural column 1 at the two ends of the wall body 10 and on the structural beam at the top of the wall body 10, the structural column 2 and the steel mesh sheet 3 are located in the wall body 10, the structural column 2 and the steel bar Mesh sheet 3 is as high as the wall body, and construction columns 2 are distributed at intervals along the length direction of the wall body. ), the steel mesh sheet 3 is vertically arranged between the structural column 2 and the structural column 1, and when there are more than two structural columns 2, the steel mesh sheet 3 is also arranged between the adjacent structural columns 2, wherein the structural The steel me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com