LED area light source modules capable of being spliced in array

An LED surface light source and array technology, applied in the field of LED surface light source modules, can solve problems such as affecting the luminous effect, improve visual effects, ensure overall sense and safety, and avoid the exposure of wires and solder joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the drawings and embodiments. The described embodiments are only part of the embodiments of the present invention. All other embodiments that are based on the embodiments of the present invention without making creative results fall within the protection scope of the present invention.

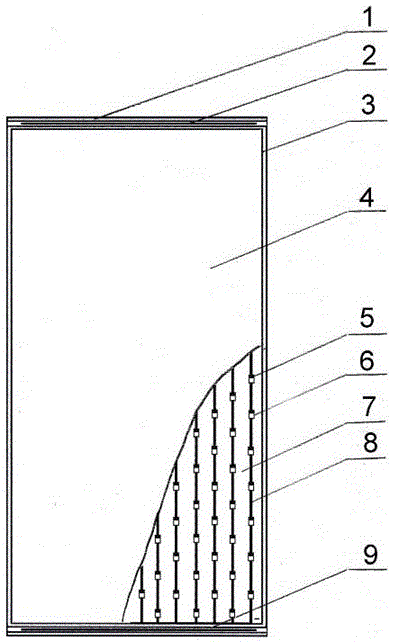

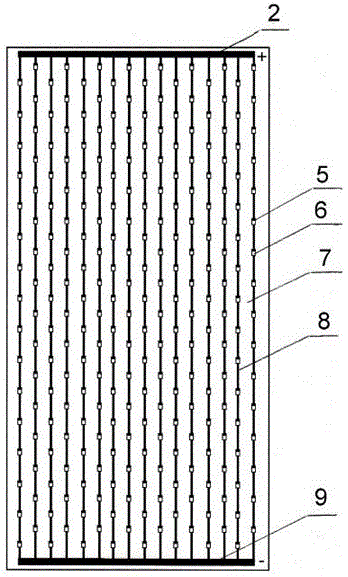

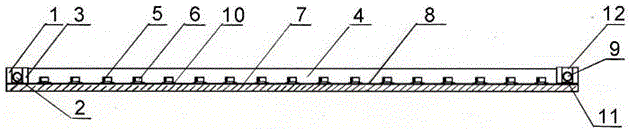

[0023] A LED surface light source module that can be arrayed and spliced. Its appearance structure and part of its internal structure are as follows: figure 1 Shown. figure 2 It is a schematic diagram of distributed connection with each group of 16 chips in series and 16 groups in parallel. image 3 It is a cross-sectional view of the module of the present invention. There are 16 flip-chips on the ceramic substrate 7. The positive terminal 5 of the flip-chip is connected to the silver wire 8 on the ceramic substrate 7 through the solder paste 10, and the 16 chips are connected in series. For the chip string, the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com