Probe of electrical vortex sensor and electrical vortex sensor

An eddy current sensor and cable technology, applied in instruments, electrical devices, electromagnetic means, etc., can solve the problems of the sensor detection displacement sensitivity and linear range reduction, low compensation accuracy, long sensor probe length, etc., to ensure the detection of displacement. Sensitivity, reduced probe size, reduced effects of eddy current field effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

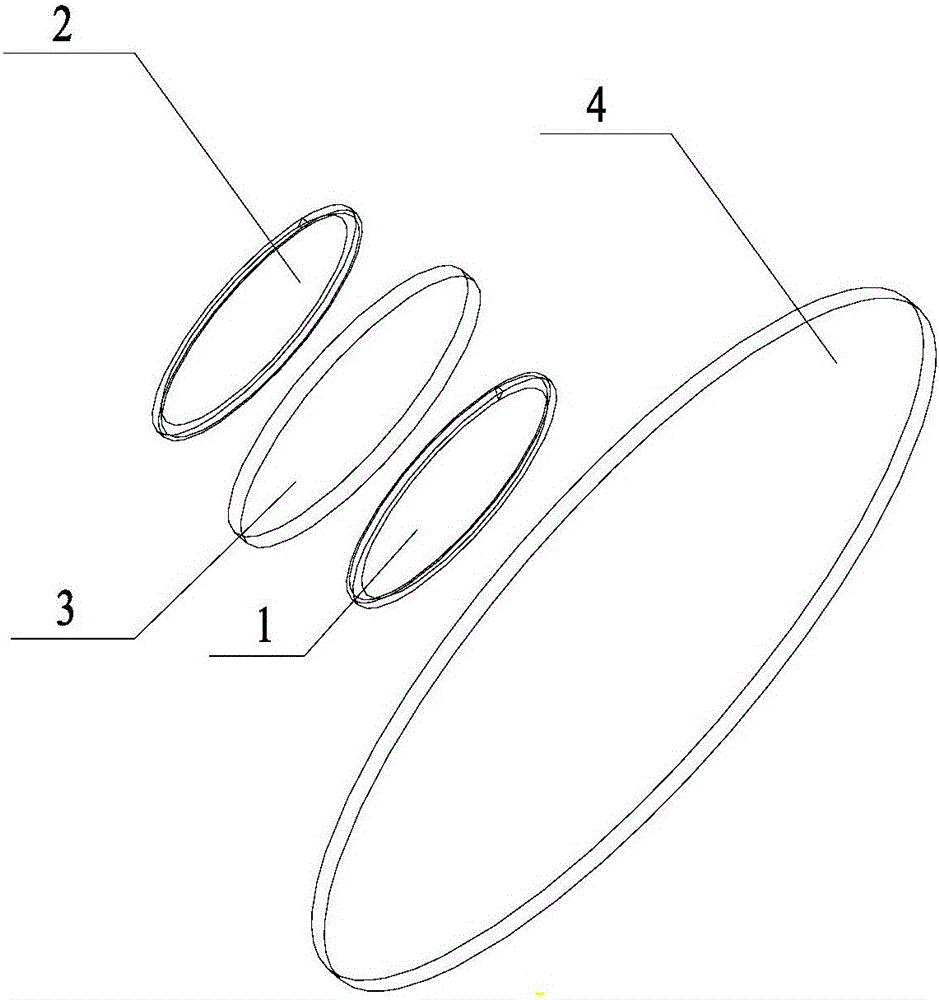

[0019] figure 1 It is a schematic diagram of the position of the coil in the probe of an eddy current sensor provided by Embodiment 1 of the present invention. This embodiment is applicable to the situation where the size of the probe is reduced on the basis of ensuring the detection accuracy, and specifically includes: detection coil 1, temperature compensation coil 2 and a magnetic isolation plate 3; the magnetic isolation plate 3 is arranged between the detection coil 1 and the temperature compensation coil 2, and is parallel to the detection coil 1 and the temperature compensation coil 2 respectively.

[0020] According to Faraday's law of electromagnetic induction, when the detection coil 1 in the probe passes a sinusoidal alternating current i 1 , the space around the detection coil 1 will inevitably produce a sinusoidal alternating magnetic field H 1 , it causes the surface of the measured metal conductor placed in this magnetic field to generate an induced current, th...

Embodiment 2

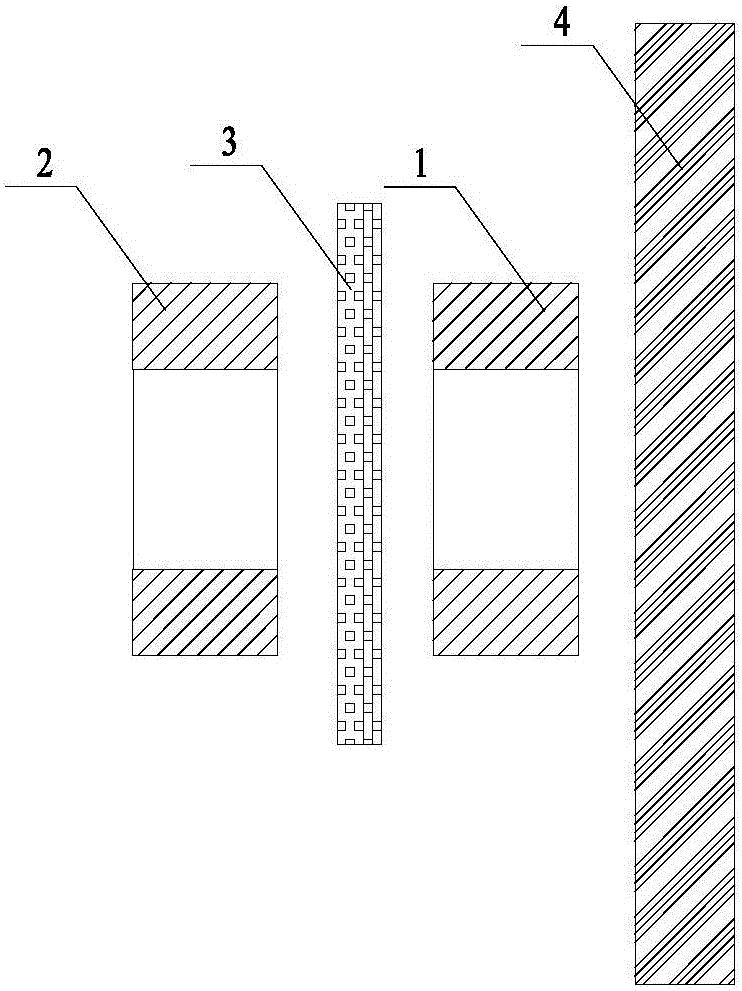

[0025] figure 2 It is a cross-sectional view of the position of the coil in the probe of an eddy current sensor in the second embodiment of the present invention. On the basis of the above-mentioned embodiments, the technical solution of this embodiment further limits the specific positions of the detection coil 1 and the temperature compensation coil 2, specifically including: the detection coil 1 and the temperature compensation coil 2 are related to the magnetic isolation Plate 3 is mirror symmetrical. When winding the coil, the same bundle of enameled wires can be wound on the frame according to the set rules by a winding machine to form the detection coil 1 and the temperature compensation coil 2 . Wherein, the set rules may be parameters manually input to the winding machine, including the number of turns of the coil, the winding method, and the distance between the coils. The advantage of such a design is to effectively ensure the consistency of parameters between th...

Embodiment 3

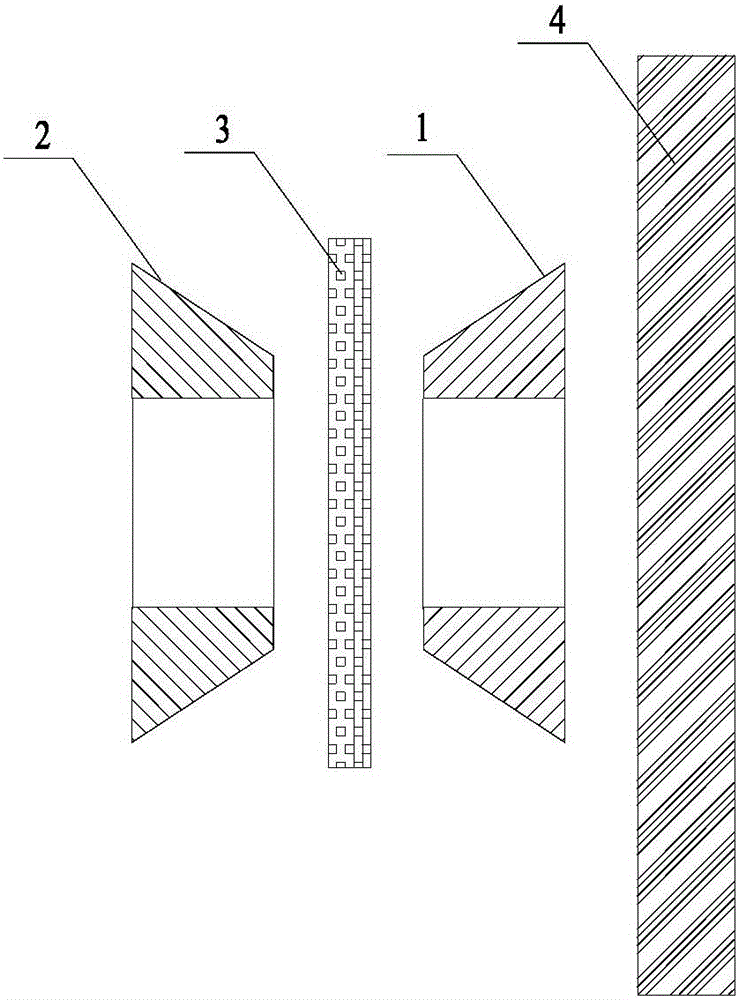

[0027] image 3It is a sectional view of the coil position in the probe of another eddy current sensor in the third embodiment of the present invention. On the basis of the above-mentioned embodiments, the technical solution of this embodiment further defines the specific shapes of the detection coil 1 and the temperature compensation coil 2, specifically including: the cross section of the detection coil 1 along the direction of the central axis is trapezoidal, and the trapezoidal The distance between the bottom surface and the detection surface is smaller than the distance between the top surface of the trapezoid and the detection surface. Although the magnetic isolation plate 3 is set between the detection coil 1 and the temperature compensation coil 2, it can isolate the magnetic field of the temperature compensation coil 2 and the magnetic field of the detection coil 1, but the electromagnetic isolation effect of the magnetic isolation plate 3 will be affected by the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com