Curved surface local normal vector measuring method based on vortex dot matrix

A measurement method and technology of normal vectors, applied in the field of detection, can solve problems such as difficulty in accurate measurement of normal vectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

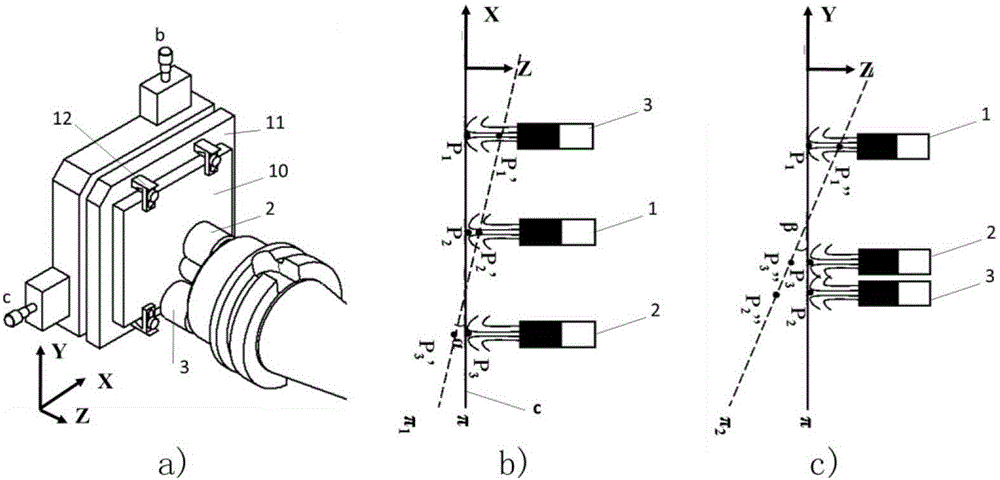

[0035] The specific implementation manner of the present invention will be described in detail in conjunction with the accompanying drawings and technical solutions.

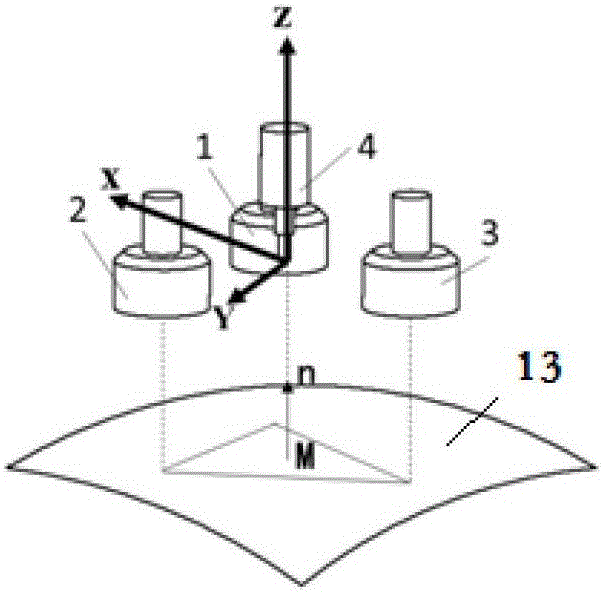

[0036] attached figure 1 -Schematic diagram of surface method vector measurement based on eddy current lattice, the tested part 13 is a cylindrical aluminum alloy part, its section arc angle is 40°, arc radius is 1m, reference busbar is 500mm, and wall thickness is 6mm. The measurement face is the outer surface of the part. The basic parameters of the three eddy current sensors are: measuring range 10mm, coil diameter 20mm, linearity 0.3%, resolution 1μm. In order to facilitate the measurement motion planning, the section trajectory is along the direction of the generatrix of the cylindrical surface, the scanning measurement method is bidirectional reciprocating measurement, and the scanning measurement speed is 200mm / min.

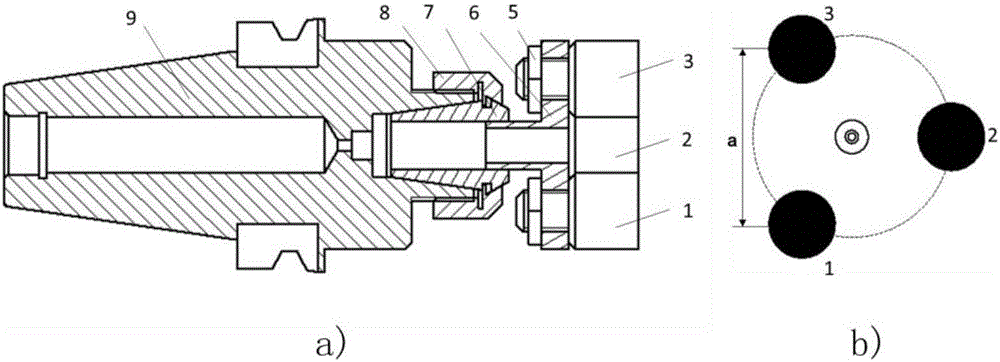

[0037] The first step is the assembly of the eddy current lattice measurement device. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com