Gum dipping device and method for testing of tensile property of carbon fiber multifilaments

A tensile property and dipping device technology, which is applied in the field of dipping devices for carbon fiber multifilament tensile performance testing, can solve the problems of unfavorable environmental protection and safe operation, large human injury, uncontrollable fiber glue content, etc. Low cost, reducing the harm to the body, beneficial to environmental protection and the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Step 1. Adjust the temperature of the test room to 25°C ± 2°C and the relative humidity to 50% ± 10%. Open all the sliding doors of the test chamber 1 and let it stand in this environment for more than 2 hours.

[0049] Step 2. Select a carbon fiber that needs to be dipped from the HF10-12K-A2 carbon fiber. The fixed length of the fiber is about 1500 meters, and it also needs to be in an environment with a temperature of 25°C±2°C and a relative humidity of 50%±10%. Leave in for more than 2 hours.

[0050] Step 3. Take the fiber ingot in step 2 and fix it on the unwinding mechanism 2 to ensure that the fiber is pulled out from the upper end.

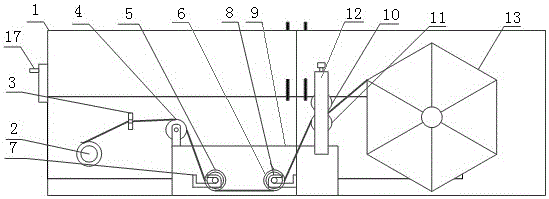

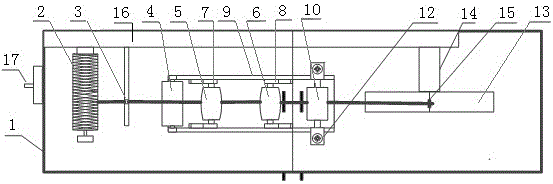

[0051] Step 4. After pulling out the fiber, it passes through the porcelain eye 3, the transmission roller 4, the first spreading roller 4, and the second spreading roller 6. °, then pass between the extruding rubber roller one 10 and the extruding rubber roller two 11, and it is fixed on the cross bar of the receiving frame 13 wi...

Embodiment 2

[0057] Step 1. Adjust the temperature of the test room to 25°C ± 2°C and the relative humidity to 50% ± 10%. Open all the sliding doors of the test chamber 1 and let it stand in this environment for more than 2 hours.

[0058] Step 2. Select 1 ingot of carbon fiber that needs to be dipped from T700SC-12K-50C carbon fiber. The fixed length of the fiber is about 1700 meters. Leave in for more than 2 hours.

[0059] Step 3. Take the fiber ingot in step 2 and fix it on the unwinding mechanism 2 to ensure that the fiber is pulled out from the upper end.

[0060] Step 4. After pulling out the fibers, they pass through the porcelain eye 3, the transmission roller 4, the first spreading roller 4, and the second spreading roller 6. °, then pass between the extruding rubber roller one 10 and the extruding rubber roller two 11, and it is fixed on the cross bar of the receiving frame 13 with the positioning clip 15.

[0061] Step 5. Add the resin system specified in the Chinese national...

Embodiment 3

[0066] Step 1. Adjust the temperature of the test room to 25°C ± 2°C and the relative humidity to 50% ± 10%. Open all the sliding doors of the test chamber 1 and let it stand in this environment for more than 2 hours.

[0067] Step 2. Select a carbon fiber that needs to be dipped from the HF30-12K-A2 carbon fiber. The fixed length of the fiber is about 1600 meters, and it needs to be placed in the environment of step 1 for more than 2 hours.

[0068] Step 3. Take the fiber ingot in step 2 and fix it on the unwinding mechanism 2 to ensure that the fiber is pulled out from the upper end.

[0069] Step 4. After pulling out the fibers, they pass through the porcelain eye 3, the transmission roller 4, the first spreading roller 4, and the second spreading roller 6. °, then pass between the extruding rubber roller one 10 and the extruding rubber roller two 11, and it is fixed on the cross bar of the receiving frame 13 with the positioning clip 15.

[0070] Step 5. Add the resin sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com