Device for detecting pressure resistant performance of camshaft oil hole plug

A detection device and camshaft technology, which is applied to the measurement device, uses stable tension/pressure to test the strength and strength characteristics of materials, etc., can solve the problems of inconvenient operation, labor and time-consuming, etc. high-efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

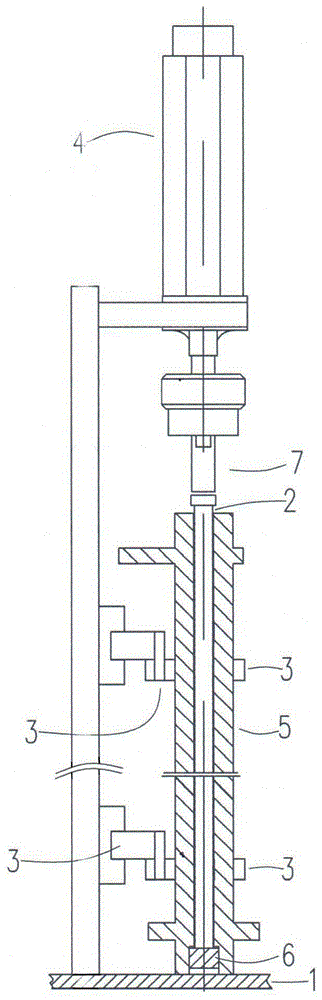

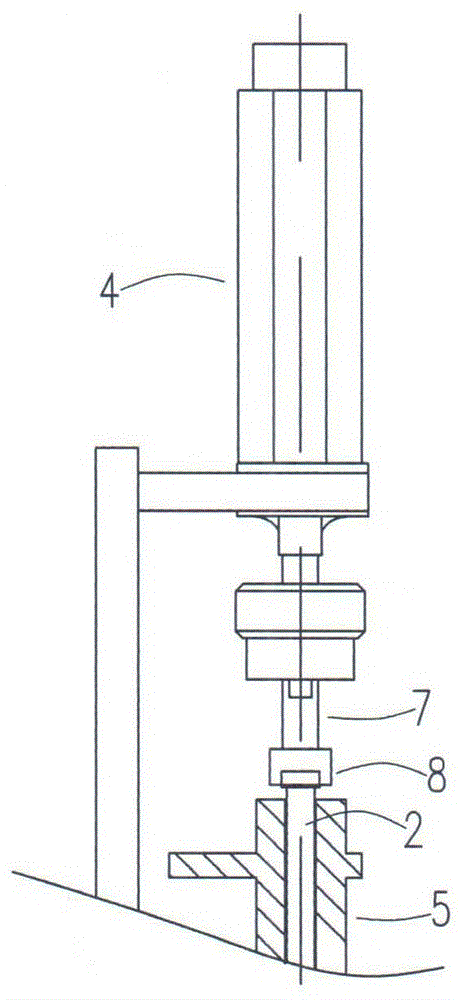

[0013] Such as figure 1 , figure 2 As shown, an embodiment of the present invention includes a base plate 1, a pressure test rod 2. The base plate 1 is provided with a camshaft positioning device 3 and a detection cylinder 4, and the length of the pressure test rod 2 is the same as that of the camshaft 5. The length is adapted, the detection cylinder 4 is equipped with a pressure sensor and a position sensor connected to the PLC; in the test state, the camshaft 5 is positioned on the base plate 1 through the camshaft positioning device 3, and the pressure test rod 2 penetrates Set in the oil passage hole of the camshaft 5, the lower end of the pressure test rod 2 is in contact with the upper end surface of the plug 6, and the upper end of the pressure test rod 2 is pressed against the indenter 7 of the detection cylinder 4, and the detection cylinder 4 is activated to the pressure test rod 2 Pressurize, the data collected by the pressure sensor and the position sensor are sent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com