Vector control underwater planktonic video inspection device

A vector control and inspection device technology, which is applied in the fields of nuclear reactor monitoring, reactor, nuclear power generation, etc., can solve the problems of late start and still in the initial stage of underwater video inspection devices, and improve inspection efficiency and video inspection image quality and weight. Light, impact-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

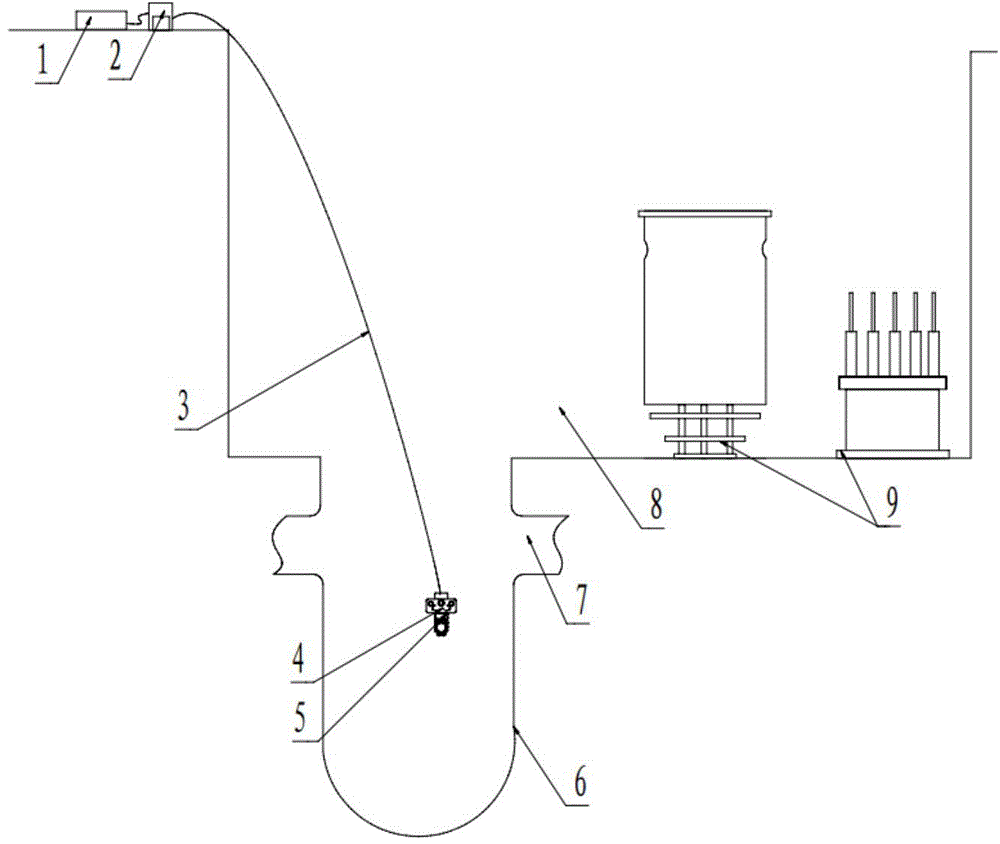

[0025] The vector-controlled underwater floating video inspection device of the present invention is an observation-type underwater robot, which has three-dimensional motion and positioning functions such as floating, diving, suspending, advancing and retreating, and turning, and the maximum working depth is not less than 50 meters underwater , the device is used for video inspection of main pipeline 7, refueling tank 8, reactor internals 9, and pressure vessel 6;

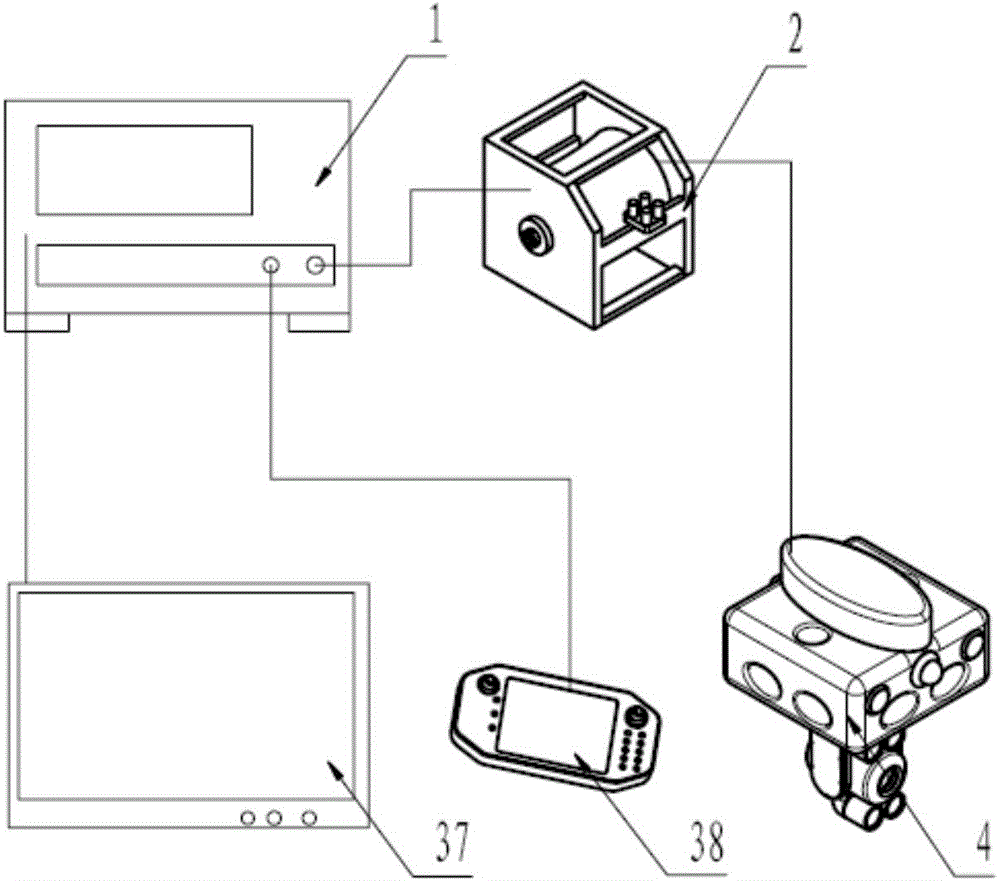

[0026] Such as Figure 1-Figure 8 As shown, the vector control type underwater floating video inspection device of the present invention includes an on-shore control system 1, an umbilical cable retractable device 2, an umbilical cable 3, a submersible body 4, and an underwater control system 5;

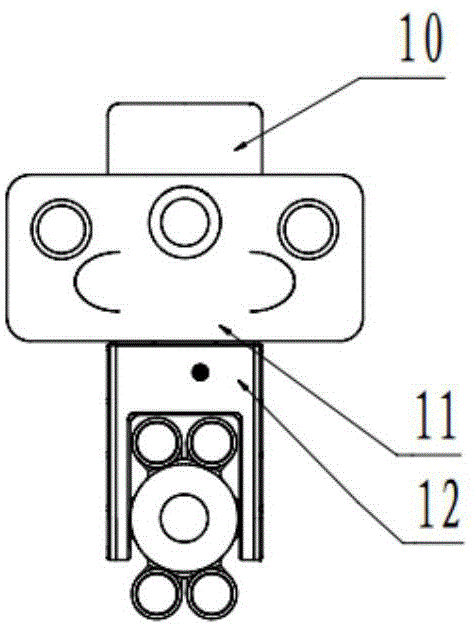

[0027] The submersible body 4 includes a floating block 10, a power platform 11, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com