Enclosed armored smokeless halogen-free non-combustible power cable

A power cable and closed technology, which is used in the field of closed armored smokeless, halogen-free and non-combustible power cables, can solve the problems of explosion in the milling system, overheating insulation, poor flame retardancy, etc., and achieves high requirements for temperature resistance and pressure resistance. Good sealing performance and excellent bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

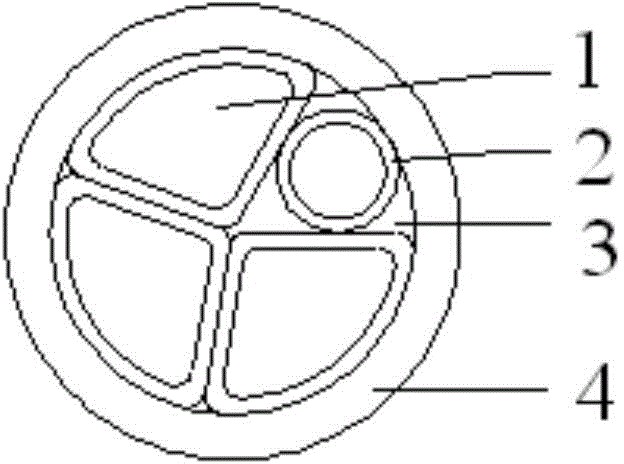

[0025] A sealed armored smoke-free, halogen-free and non-combustible power cable, the structure of which is as follows figure 1 As shown, it includes a metal armor sheath 4, an insulating layer 2 and a conductor 1 arranged sequentially from the outside to the inside, and a filler is also provided between the metal armor sheath 4 and the insulation layer 2. The metal armor sheath adopts The metal armor sheath is made of 304 stainless steel tape. The composition does not contain halogens.

[0026] The metal armor sheath 4 is made of metal strips welded by the welding and embossing production line and then formed into a tube to cover the cable core. After the embossing ring is embossed, the appearance of the metal armor sheath is in the shape of spiral rings, making the cable soft Increased degree for easy bending. In addition, the metal armor sheath 4 is isolated from the conductive wire core by an insulation layer, a wrapping layer, etc., so that there is no risk of electric ...

Embodiment 2

[0029] A closed armored smoke-free, halogen-free and non-combustible power cable, including a sheath, an insulating layer and a conductor arranged in sequence from the outside to the inside, and a filler is provided between the sheath and the insulating layer, and the sheath is welded corrugated metal Armored sheath, the metal armored sheath adopts TUIM copper tape. The composition does not contain halogens.

[0030] The metal armored sheath is made of metal strips welded by the welding and embossing production line and then formed into a tube to cover the cable core. After the embossed ring is embossed, the appearance of the metal armored sheath is in the shape of spiral rings, which makes the cable softer. increased for easy bending. In this embodiment, one conductor is provided, and the cross section is circular.

Embodiment 3

[0032] A closed armored smoke-free, halogen-free and non-combustible power cable, including a sheath, an insulating layer and a conductor arranged in sequence from the outside to the inside, and a filler is provided between the sheath and the insulating layer, and the sheath is welded corrugated metal Armored sheath, the metal armored sheath adopts H18 aluminum tape. The composition does not contain halogens.

[0033] The metal armored sheath is made of metal strips welded by the welding and embossing production line and then formed into a tube to cover the cable core. After the embossed ring is embossed, the appearance of the metal armored sheath is in the shape of spiral rings, which makes the cable softer. increased for easy bending. In this embodiment, there is only one conductor, and the cross section is fan-shaped.

[0034] The invention utilizes the incombustibility, non-toxicity and high temperature resistance of the metal armor sheath layer, so that the power cable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com