Transmission electron microscope sample table for observing three-dimensional atom probe test sample

A transmission electron microscope sample and atom probe technology, which is applied to circuits, discharge tubes, electrical components, etc., can solve the problems of low success rate, inconvenient operation, and small application range, and achieve the effect of convenient operation and one-handed operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

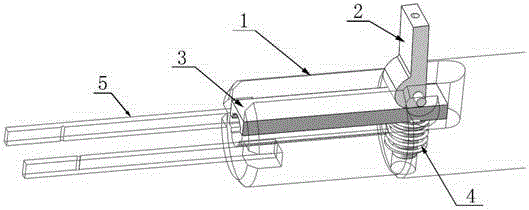

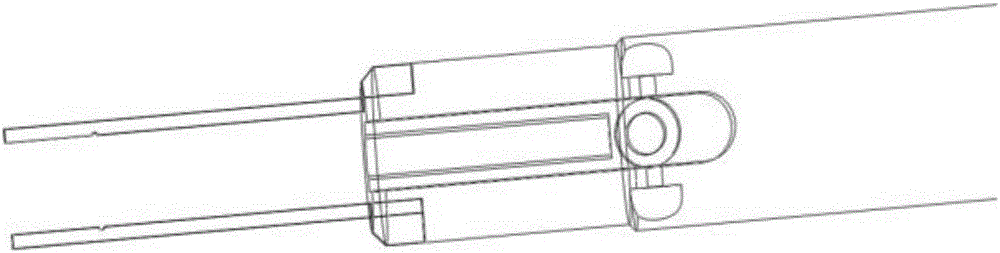

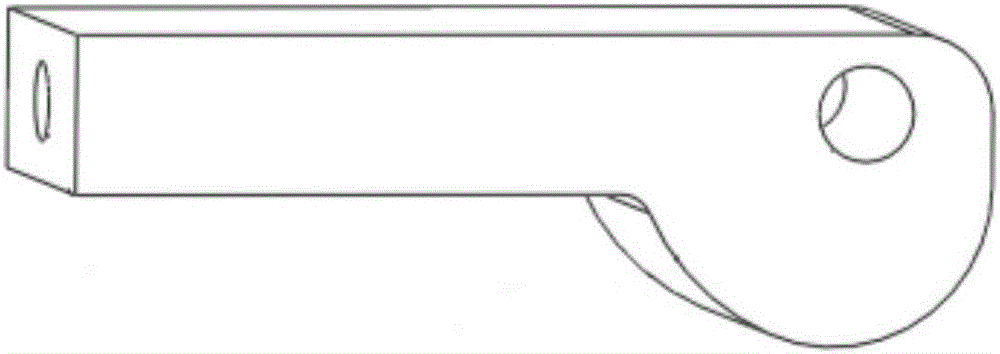

[0050] In this embodiment, an improvement is made on the sample rod body 1 of the existing transmission electron microscope sample rod. The above-mentioned structure is adopted, and two guide rods are provided for independent processing, and then inserted into the slot of the sample rod body by interference fit. The maximum outer edge distance between two guide rails is 4.3mm, the guide rail width is 1mm, and the height is 1mm. The notches for the clamp and eccentric are 13mm long and 2.5mm wide, and run from the top of the sample holder body all the way to the center. In order to facilitate the smooth movement of the pressing block up and down, a semi-cylindrical tail that matches the width and height of the notch is added to the rear end of the notch. At the bottom of the notch, a circular arc-shaped bottom groove and a rectangular step are designed according to the shape and size of the sample-carrying copper tube and the professional clamping platform, so as to position th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com