Thin-film transistor substrate, manufacturing method thereof and display panel

A technology of a thin film transistor and a manufacturing method, which is applied in the field of thin film transistor substrates, can solve problems such as light leakage and transmittance reduction, and achieve the effects of reducing light leakage, increasing resolution, and improving display effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

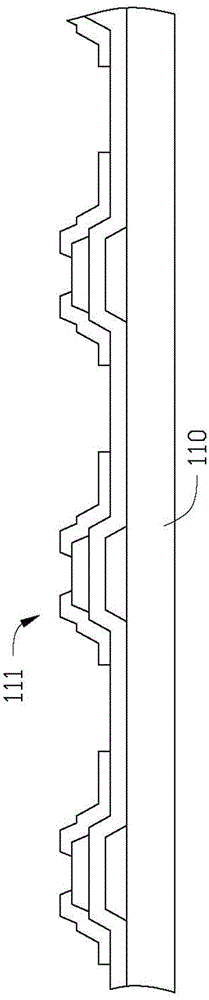

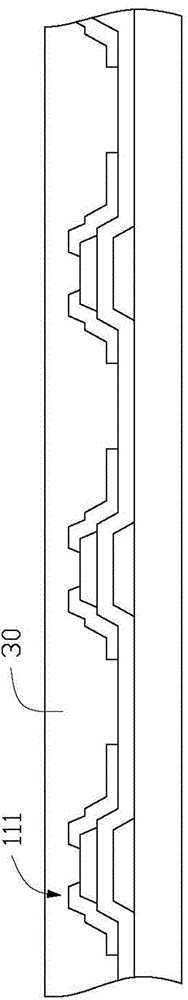

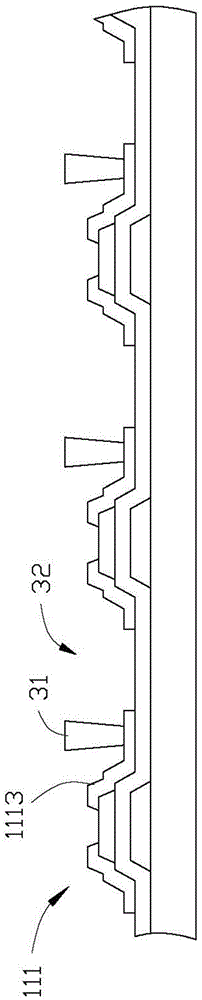

[0021] Please also see Figures 1 to 9 , which is a cross-sectional view of each step of the manufacturing method of the thin film transistor substrate 11 according to a preferred embodiment of the present invention. The method comprises the steps of:

[0022] Step S01, such as figure 1 As shown, a first substrate 110 is provided, and a plurality of thin film transistors 111 are formed on the first substrate 110 .

[0023] Step S02, such as figure 2 As shown, a first photoresist layer 30 is formed on the first substrate 110 and the thin film transistors 111 , and the first photoresist layer 30 covers a plurality of the thin film transistors 111 . In this embodiment, the first photoresist layer 30 is a positive photoresist.

[0024] Step S03, such as image 3 As shown, the first photoresist layer 30 is patterned to form a spacer 31 at a position above the drain 1113 of the thin film transistor 111 . There are gaps 32 between adjacent spacers 31 . In this embodiment, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com