A current carrier chip assembly machine and assembly method

A technology for tape and assembler, which is applied to conveyor objects, transportation and packaging, climate sustainability, etc., can solve the problems of poor production quality, difficult to meet processing requirements, low efficiency, etc., to achieve smooth process action, avoid Excessive complexity, to meet the effect of large-scale continuous production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below according to the drawings and embodiments.

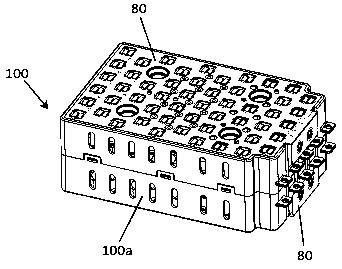

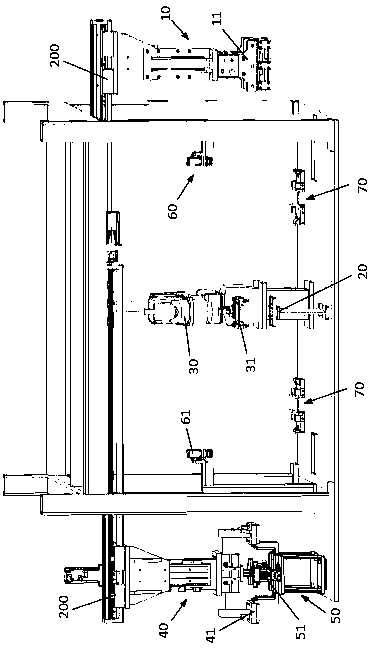

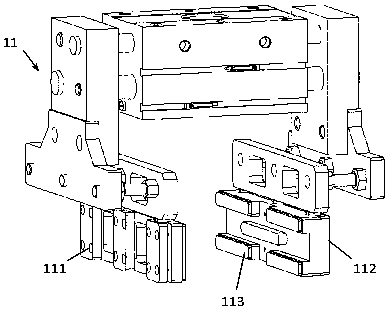

[0031] Such as figure 1 and figure 2 As shown, a current carrier assembly machine according to the embodiment of the present invention includes: an assembly station 20, which is used to undertake the assembly of the loading tape 80 and the casing 100a after the battery is inserted into the shell; the handling and feeding device 10, It is used to transport the shell 100a after the battery is inserted into the shell to the assembly station 20, including the first pneumatic gripper 11 that can be lifted and translated; The chip head 31 obtains the current carrier 80 and places the current carrier 80 on the upper and lower sides of the housing 100a respectively to form the assembly 100; the conveying and unloading device 40 includes a movable pressing assembly 100 The second pneumatic gripper 41.

[0032] The first current carrier is placed on the assembly statio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com