Active power output control parameter pre-processing method for hydropower station during automatic power generation

A technology of automatic power generation and control parameters, applied in the direction of single-network parallel feeding arrangement, etc., can solve problems such as unreliable water head reliability suggestions, unresolved time statistics, priority calculation power allocation, unresolved issues, etc., to reduce program complexity performance, improve the robustness of the program, and improve the efficiency of the solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0030] The present invention provides a method for preprocessing parameters of active power output control parameters of automatic power generation in hydropower stations, including the following operations:

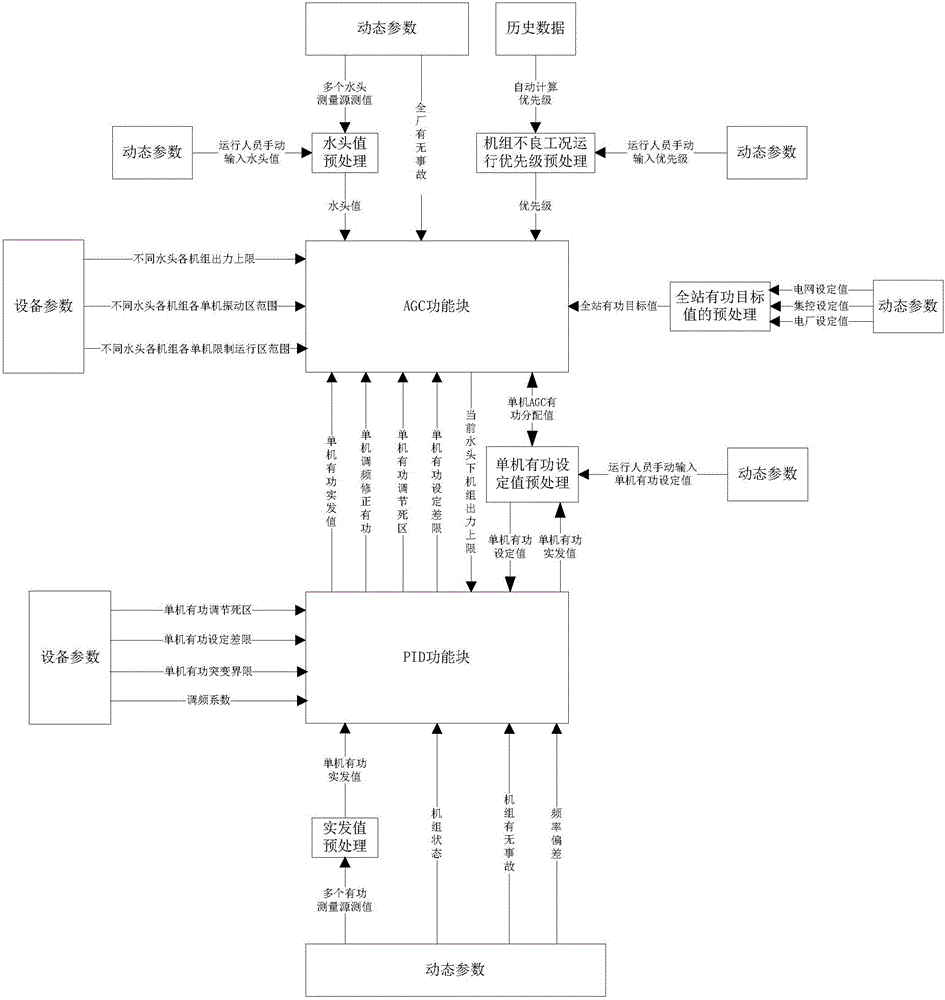

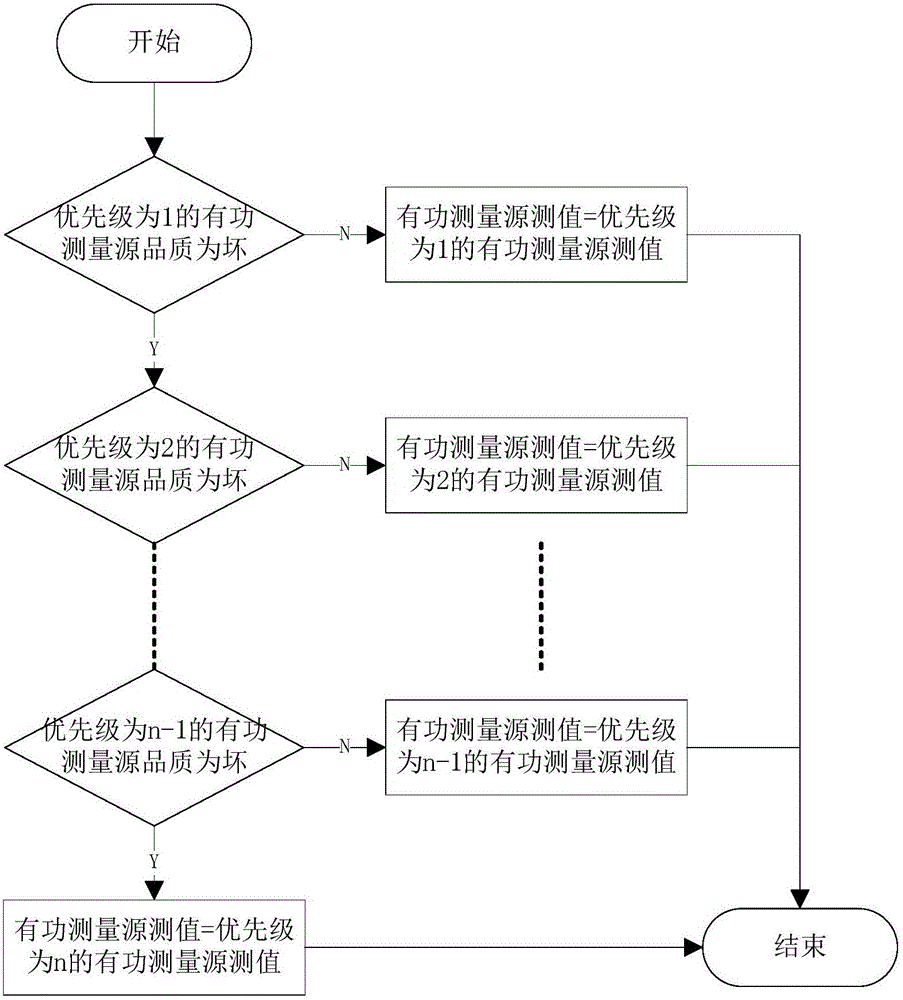

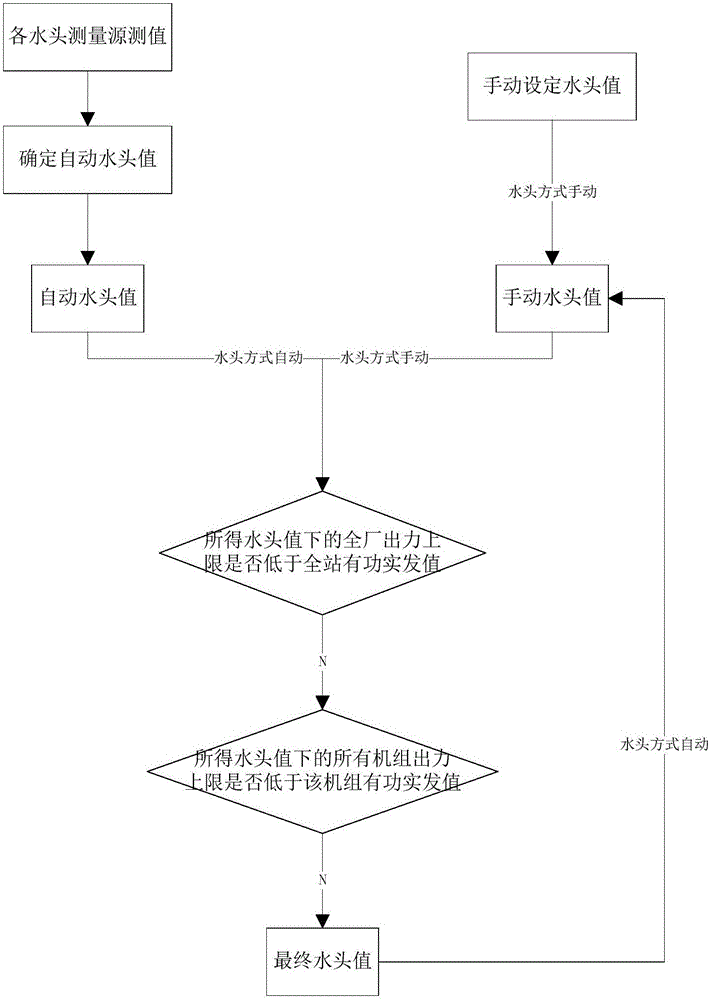

[0031] Divide the core functions of automatic power generation control of hydropower stations into two functional blocks of AGC and PID for processing; the preprocessing parameters are first input into the preprocessing functional block for processing, and then sent to the two functional blocks of AGC and PID, and directly sent Equipment parameters and dynamic parameters participate in the generation of intermediate parameters, which are called when the AGC function block is used to establish the combined output model of the hydropower generating set and perform active power distribution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com