Control of rotating field machine

A technology of rotating field and control equipment, applied in the field of feedback control, which can solve the problems of electric power reduction of rotating field motors, problems of heat export, and temperature rise of series resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

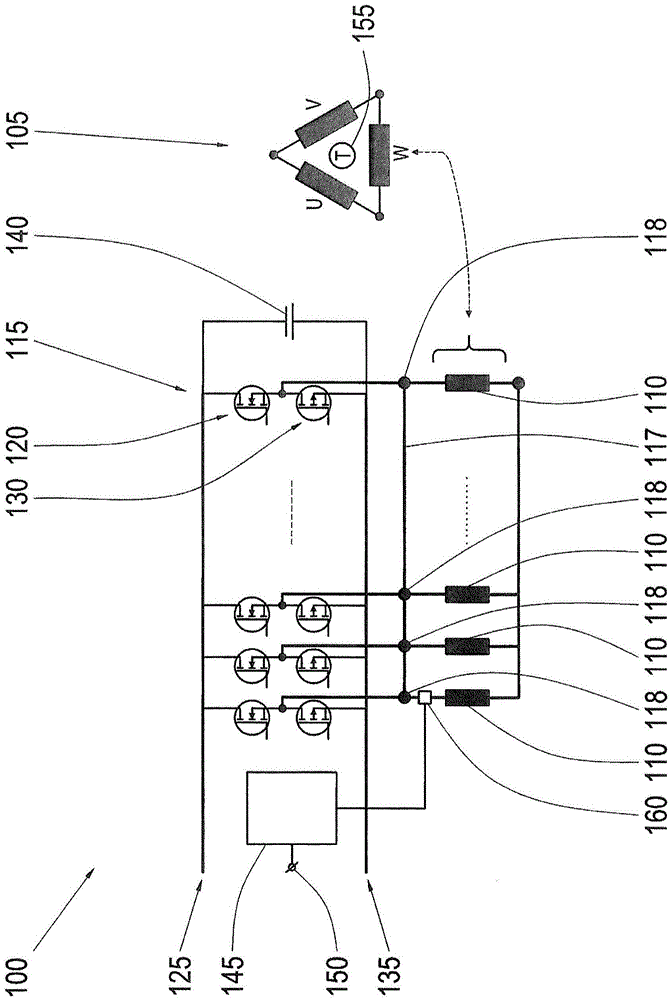

[0016] figure 1 A circuit diagram of the components of a control device 100 for controlling a rotating field motor 105 is shown. The rotating field machine 105 can be used in particular in a motor vehicle, for example as a generator, starter or in particular as an integrated starter generator. The rotating field electric machine 105 generally comprises P phases, of which three phases U, V and W are exemplified here. Each phase comprises a plurality of windings 110 which are connected in parallel to one another and are preferably constructed identically. exist figure 1 In the illustration of , only the components relating to phase W are shown in more detail, the other phases U and V being driven in a corresponding manner.

[0017] A half-bridge 115 is provided to provide a predetermined voltage at the connections of the phase W. Half-bridge 115 includes a first current valve 120 for connecting the terminal to high potential 125 and a second current valve (“low-side switch”)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com