Asphalt resin anti-sloughing agent for drilling fluid, and preparation method of asphalt resin anti-sloughing agent

A technology of asphalt resin and anti-slump agent, which is applied in the field of asphalt resin anti-slump agent for drilling fluid and its preparation, can solve problems such as easy well collapse, increase well wall stability, enhance flexibility and heat resistance, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

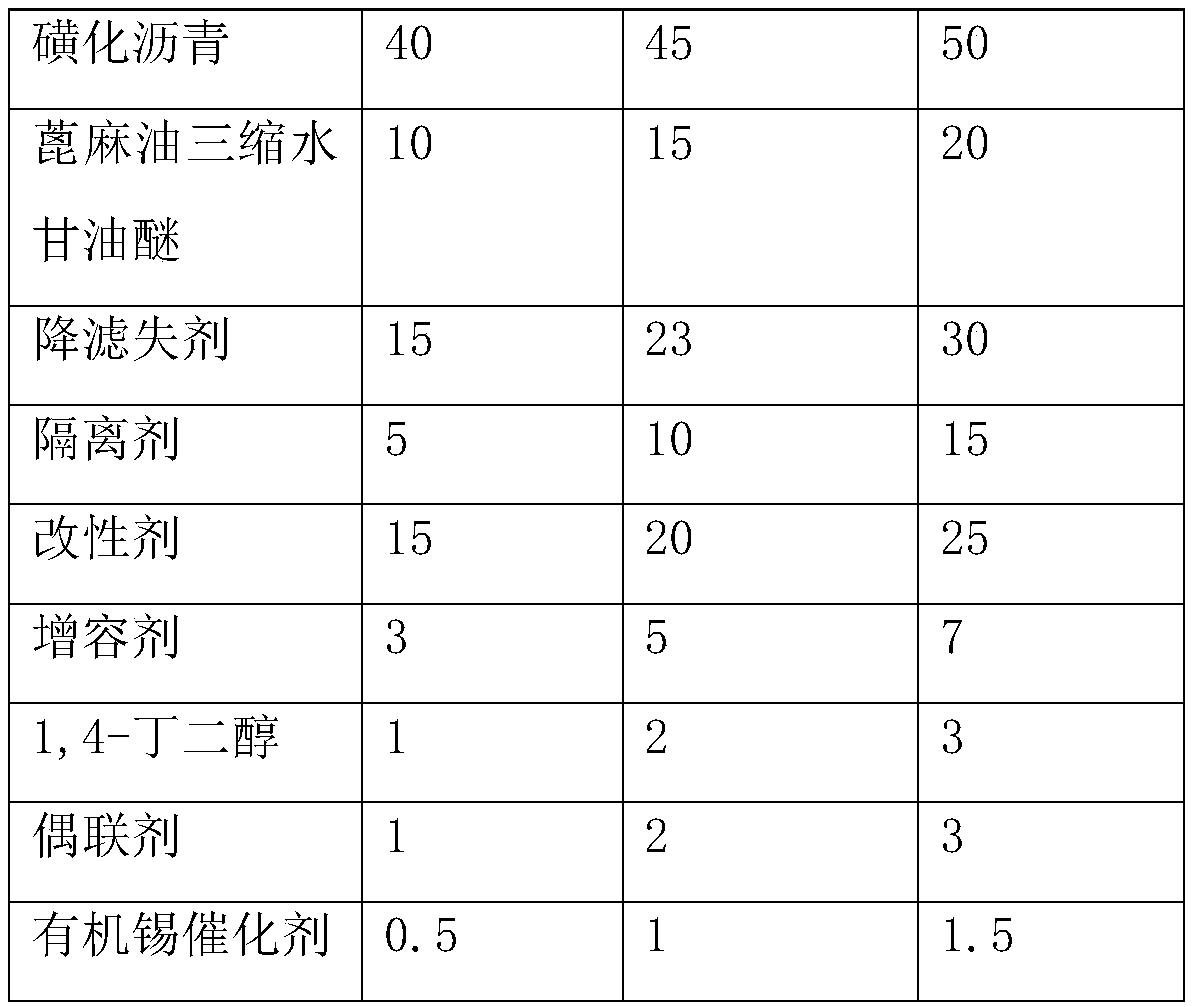

Examples

preparation example 1-3

[0038] In Preparation Example 1-3, the chlorinated palm oil methyl ester is selected from the model RY-118 chlorinated palm oil methyl ester sold by Dongguan Ruiyun Environmental Protection Technology Co., Ltd., and the precipitated silica is selected from Shijiazhuang Datai Chemical Technology Co., Ltd. Precipitated silica for sale with type A130

preparation example 1

[0039] Preparation example 1: (1) Disperse 2kg of graphite oxide in 40kg of water, and disperse for 1h under 400w ultrasonic conditions to obtain an aqueous solution of graphene oxide; mix 8kg of sodium hydroxide, 3kg of urea and 80kg of water to prepare a solution, and prepare a solution at -10 Freeze at ℃ for 8 hours, add 5kg of starch, stir at 0℃ for 4 hours, slowly warm up to room temperature, add 3kg of chloropalm oil methyl ester and 2kg of precipitated silica, and mix well to obtain a starch solution, the particle size of precipitated silica 400 mesh;

[0040] (2) Mix the starch solution and the graphene oxide solution at a mass ratio of 10:2.5, sonicate for 30 minutes, filter with a polytetrafluoroethylene membrane, wash with deionized water until neutral, vacuum-dry at 60°C, and grind for 200 Mesh sieve.

preparation example 2

[0041] Preparation example 2: (1) Disperse 3kg of graphite oxide in 60kg of water, and disperse it under 450w ultrasonic conditions for 0.8h to obtain an aqueous solution of graphene oxide; mix 10kg of sodium hydroxide, 5kg of urea and 83kg of water to prepare a solution, and put it in - Freeze at 10°C for 9 hours, add 8kg of starch, stir at 0°C for 5h, slowly warm up to room temperature, add 4kg of chlorinated palm oil methyl ester and 4g of precipitated silica, and mix well to obtain a starch solution and precipitated silica particles The diameter is 400 mesh;

[0042] (2) Mix the starch solution and the graphene oxide solution at a mass ratio of 10:2.7, sonicate for 40 minutes, filter with a polytetrafluoroethylene membrane, wash with deionized water until neutral, dry in vacuum at 70°C, and grind for 200 Mesh sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com