Optical module lighting power control system and control method therefor

A technology of optical power control and optical modules, which is applied in light sources, electric light sources, lighting devices, etc., can solve the problems of relatively large fluctuations in the output optical power of lasers, the inability to maintain constant output optical power, and the inability to adapt to changes in laser characteristics. Work efficiency, burnout prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

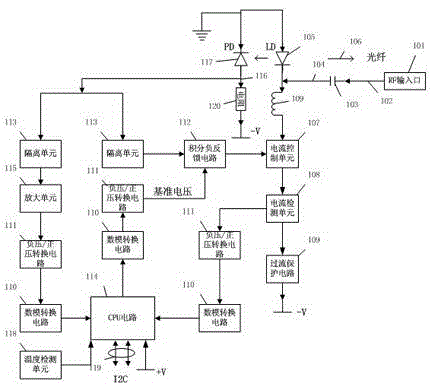

Embodiment 1

[0045] Implementation of the present invention at first sight figure 2 , mainly including RF input port 101, microstrip line 102, DC blocking capacitor 103, microstrip matching line 104, laser LD105, laser backlight detector PD117, circuit line 116, broadband inductor 121, sampling resistor 120, current control unit 107 , current detection unit 108, overcurrent protection circuit 109, negative pressure / positive pressure conversion circuit 111, digital-to-analog conversion circuit 110, integral negative feedback circuit 112, isolation unit 113, CPU circuit 114, amplifier circuit 115 and temperature detection unit 118.

[0046] The microwave signal is input from the RF input port 101 and transmitted through the microstrip line 102. It must be blocked by a DC blocking capacitor 103 to isolate the DC voltage of the optical power control system of the optical module from being affected by the outside. After the microwave signal passes through the DC blocking capacitor 103 , modula...

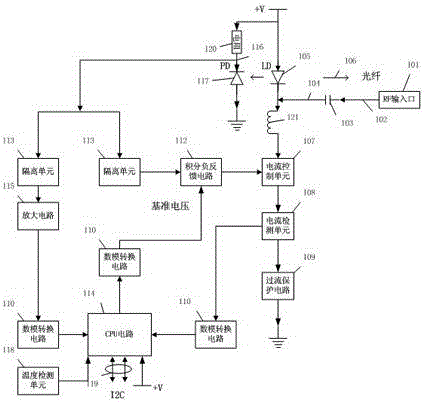

Embodiment 2

[0052] Embodiment 2 of the present invention sees image 3 , mainly including RF input port 101, DC blocking capacitor 103, microstrip matching line 104, laser LD105, laser backlight detector PD117, broadband inductor 121, sampling resistor 120, current control unit 107, current detection unit 108, overcurrent protection circuit 109 , digital-to-analog conversion circuit 110 , integral negative feedback circuit 112 , isolation unit 113 , CPU circuit 114 , amplification circuit 115 and temperature detection unit 118 .

[0053]The microwave signal is input from the RF input port 101 and transmitted through the microstrip line 102. It must be blocked by a DC blocking capacitor 103 to isolate the DC voltage of the optical power control system of the optical module from being affected by the outside. After the microwave signal passes through the DC blocking capacitor 103 , modulated on the laser LD105 by the microstrip matching line 104, and the modulated laser signal is output thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com