Spring tightening device, jaw crusher, processing plant of mineral material and method for compressing or decompressing spring loading tie rod in jaw crusher

A jaw crusher and locking device technology, applied in the field of spring locking, can solve the problems of difficulty in locking the spring, large force and multiple tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In the following description, like reference numerals denote like elements. It should be noted that the drawings are not in all cases drawn to scale and that they are mainly for the purpose of illustrating embodiments of the invention.

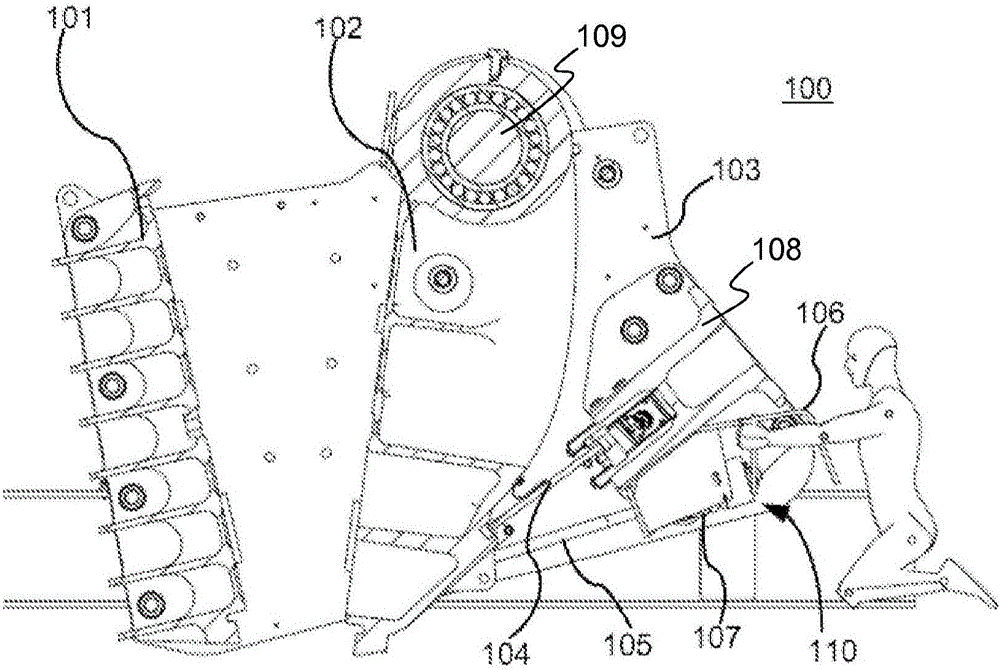

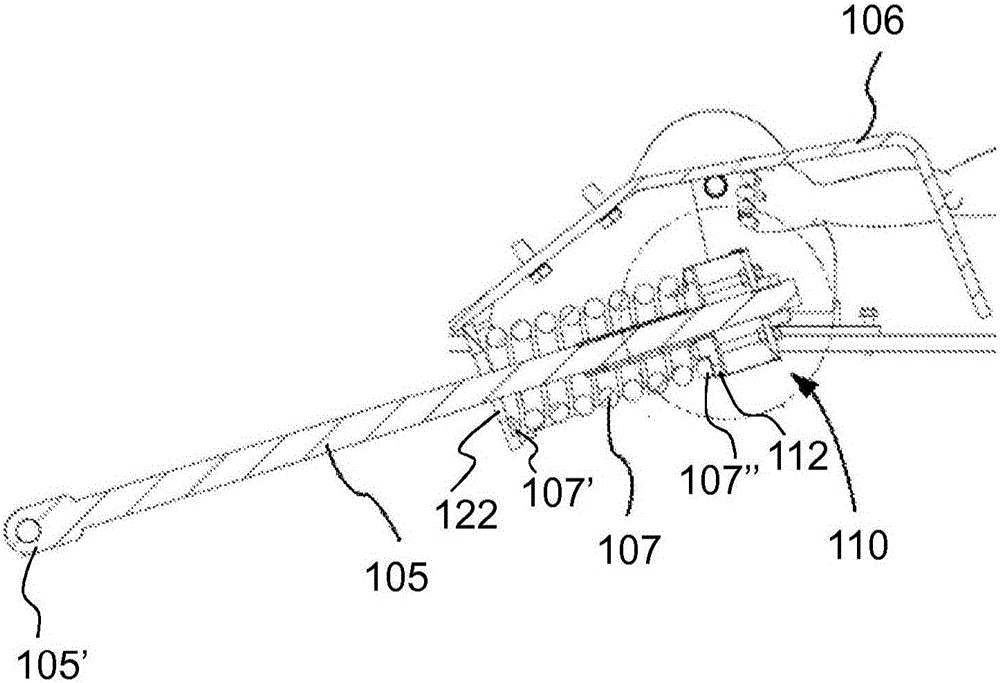

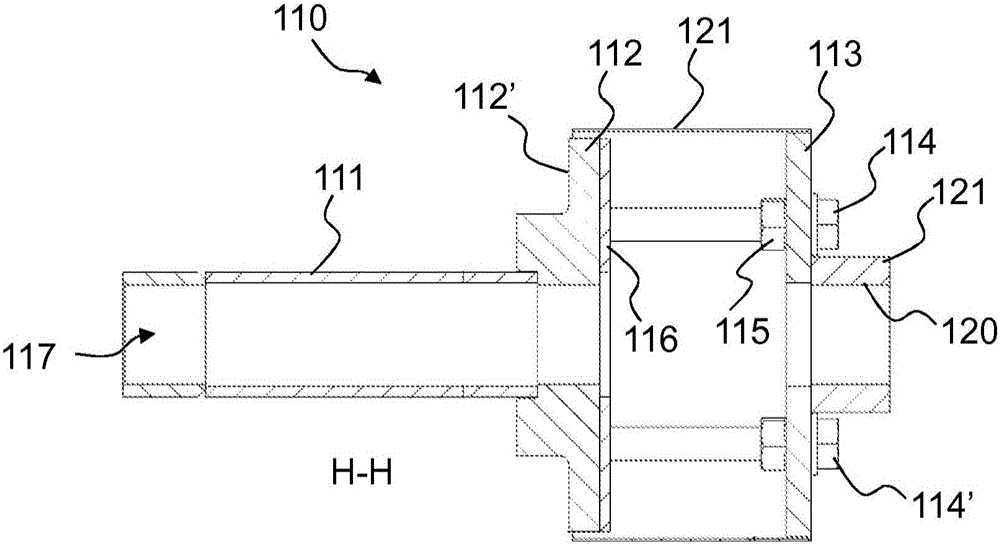

[0059] figure 1Shown is a jaw crusher 100 comprising: a fixed jaw 101 as the front part of the jaw crusher; Type crusher frame side plate 103 support. The rear part 108 of the frame of the jaw crusher is fastened between these side plates. The pendulum is supported by the rear of the frame through toggle plate 104 . Furthermore, a tie rod 105 is arranged between the lower end of the pendulum and the rear part 108 of the frame; the tie rod is loaded by a spring 107 . When the spring 107 is locked, the pull rod pulls the pendulum 102 back against the toggle plate 104 . With the locking device 110 according to a preferred embodiment of the present invention, the spring acting on the pull rod is mounted in place. The jaw crusher inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com