Ceramic press powder grating and ceramic brick forming system and production line using same

A powder grid and press technology, which is applied in the field of architectural ceramics, can solve the problems of blockage of the air outlet of the mold, affecting the fluidity of the powder, and the decrease of the fluidity of the ceramic powder, so as to avoid damage, increase the service life, and increase the density. evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

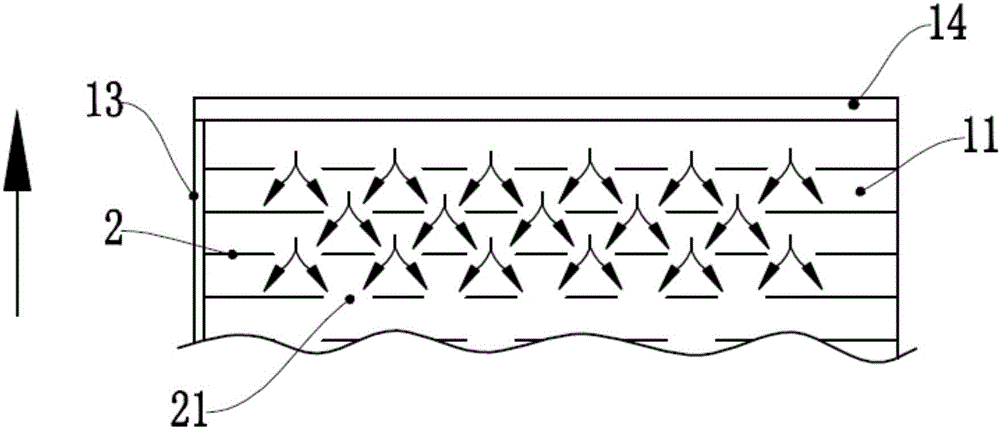

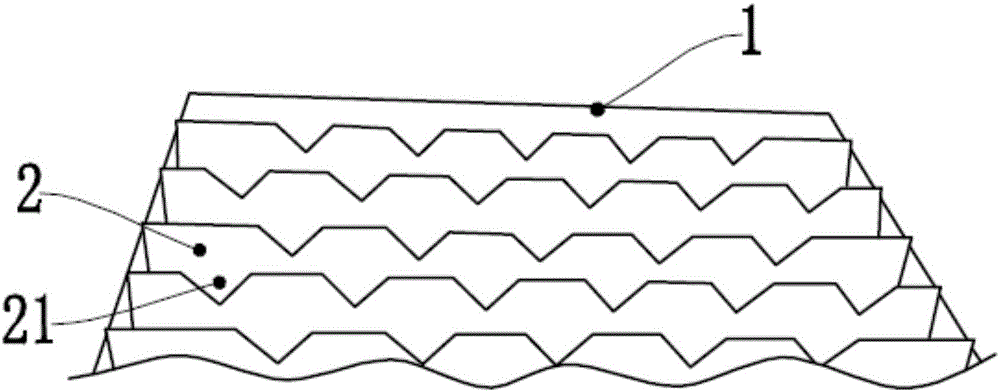

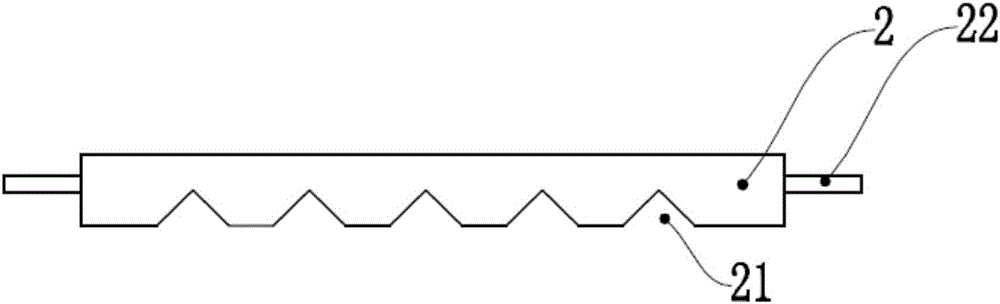

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0032] In this embodiment

[0033] A ceramic press powder grid (such as Figure 1-3 As shown), it includes a grid frame 1 and several partitions 2, the grid frame 1 is surrounded by longitudinal ribs 13 and transverse ribs 14, and the partitions 2 are horizontally arranged in the grid frame 1, and the The grid frame 1 is divided into several rectangular powder filling areas 11 , and a number of powder openings 21 are provided on one side of the separator 2 , so that two of the powder filling areas 11 communicate with each other. Preferably, the powder openings 21 of the two spacers 2 are staggered from each other.

[0034] The powder grid of the ceramic press in this embodiment, when in use, the distributing machine lays ceramic powder 3 on it, and the ceramic powder 3 is sprinkled on the powder f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com