High-voltage insulation gas circuit distributor for high-speed motor train unit

A high-speed EMU, high-voltage insulation technology, applied in motor vehicles, electric vehicles, collectors, etc., can solve the problems of wind duct head-on creepage, can not meet the requirements of high-speed rail safe operation, hidden dangers and other problems, to improve the creepage distance, Guaranteed reliability and economy, good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

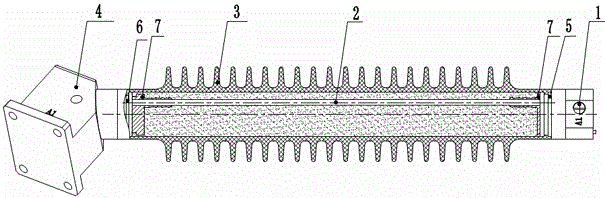

[0018] like figure 1 As shown, a high-voltage insulating gas circuit distributor for high-speed EMUs provided by this embodiment includes a distributor body, an upper connecting part 1, a lower connecting part 4, an airway core 2 and an outer insulating umbrella group 3. The upper end connecting part 1 and the lower end connecting part 4 are installed at both ends of the distributor body, the outer insulating umbrella group 3 is distributed on the outer peripheral end of the distributor body and is integrally injection molded with the distributor body, the airway core 2 is placed At the inner end of the distributor body, the airway core is made of high-strength elastic polyurethane, the outer insulating umbrella group 3 and the distributor body are made of high-temperature vulcanized silicone rubber, and the ports of the upper connecting part 1 and the lower connecting part 4 are provided with A plurality of upper connecting part air channels 5 and lower connecting part air ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com