Preparation method of stable ferrous hydroxide

A ferrous hydroxide, stable technology, applied in the field of chemistry teaching, can solve problems such as not being suitable for classroom demonstrations, potential safety hazards, and potential safety hazards, and achieve the effects of low cost, simple process, and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

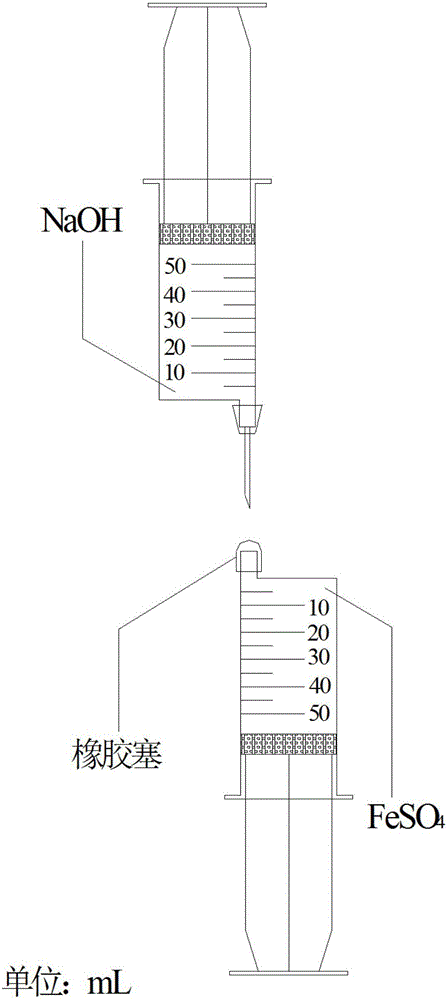

[0041] A preparation method for stable ferrous hydroxide, comprising steps as follows:

[0042] (1) Take dissolved NaOH, FeSO 4 ·7H 2 O distilled water and distilled water to be used are heated to 98°C and boiled for 5 minutes. At the same time, nitrogen gas is passed into the boiling water at a constant speed of 95 SCCM, and then the boiling water is cooled to room temperature to obtain distilled water that dissolves NaOH after treatment, and dissolves FeSO after treatment. 4 ·7H 2 O distilled water, distilled water for use after processing;

[0043] (2) Take 100ml of distilled water that dissolves NaOH after treatment, add 1.6g of NaOH and stir to dissolve to obtain NaOH solution, take 100ml of treatment and dissolve FeSO 4 ·7H 2 O distilled water, add 5.56g FeSO 4 ·7H 2 O was stirred and dissolved to obtain FeSO 4 solution, keep feeding nitrogen during the preparation process, and the speed of nitrogen feeding is 60SCCM; 4 Add reduced iron powder into the solution, ...

Embodiment 2

[0052] A preparation method for stable ferrous hydroxide, comprising steps as follows:

[0053] (1) Take dissolved NaOH, FeSO 4 ·7H 2 The distilled water of O and the distilled water to be used are heated to 96°C and boiled for 6 minutes. At the same time, nitrogen gas is passed into the boiling water at a constant speed of 90 SCCM, and then the boiling water is cooled to room temperature to obtain distilled water that dissolves NaOH after treatment, and dissolves FeSO after treatment. 4 ·7H 2 O distilled water, distilled water for use after processing;

[0054] (2) Take 100ml of distilled water that dissolves NaOH after treatment, add 1.6g of NaOH and stir to dissolve to obtain NaOH solution, take 100ml of treatment and dissolve FeSO 4 ·7H 2 O distilled water, add 5.56g FeSO 4 ·7H 2 O was stirred and dissolved to obtain FeSO 4 solution, keep feeding nitrogen during the preparation process, and the speed of nitrogen feeding is 60SCCM; 4 Add reduced iron powder into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com