Electrophoretic paint recycling device

A recycling device and electrophoretic paint technology, applied in the field of electrophoretic paint, can solve problems such as short lifespan, and achieve the effects of short process, low maintenance cost and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

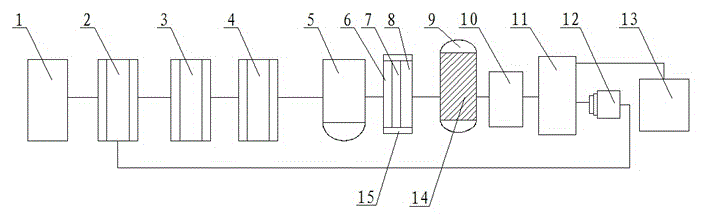

[0018] This embodiment includes a battery swimming pool 1, a primary washing pool 2, a secondary washing pool 3, a tertiary washing pool 4, a precision filter 5, activated carbon 14, a filter 9, an ultrafiltration device 10, a secondary filter 11, and a water pump 12 , low-concentration cleaning pool 13, activated carbon 14, macromolecule separation device 15, battery pool 1 is connected to primary washing pool 2, primary washing pool 2 is connected to secondary washing pool 3, secondary washing pool 3 is connected to third-level washing pool 4, The three-stage washing pool 4 is connected to the precision filter 5, the precision filter 5 is connected to the macromolecular separation device 15, the macromolecular separation device 15 is connected to the activated carbon 14 filter 9, the activated carbon 14 filter 9 is connected to the ultrafiltration device 10, and the ultrafiltration device 10 is connected The secondary filter 11 is connected to the water pump 12 and the low-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com