Oil and gas separator with adjustable flow and parallel multi-branches

一种油气分离器、多支路的技术,应用在机器/发动机、用于弹性流体的泵送装置的部件、旋转活塞式/摆动活塞式的泵部件等方向,能够解决无法满足动力用螺杆压缩机试验系统宽量程高效率低成本等问题,达到除油效果良好、有利于分离、提高除油效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

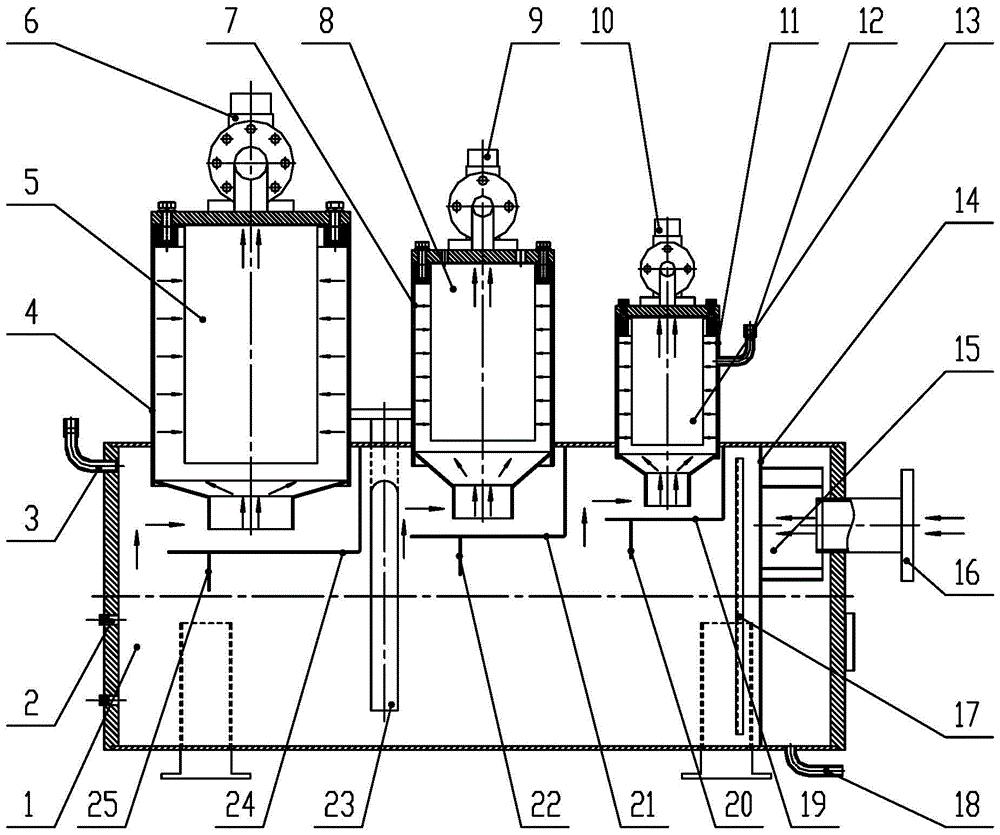

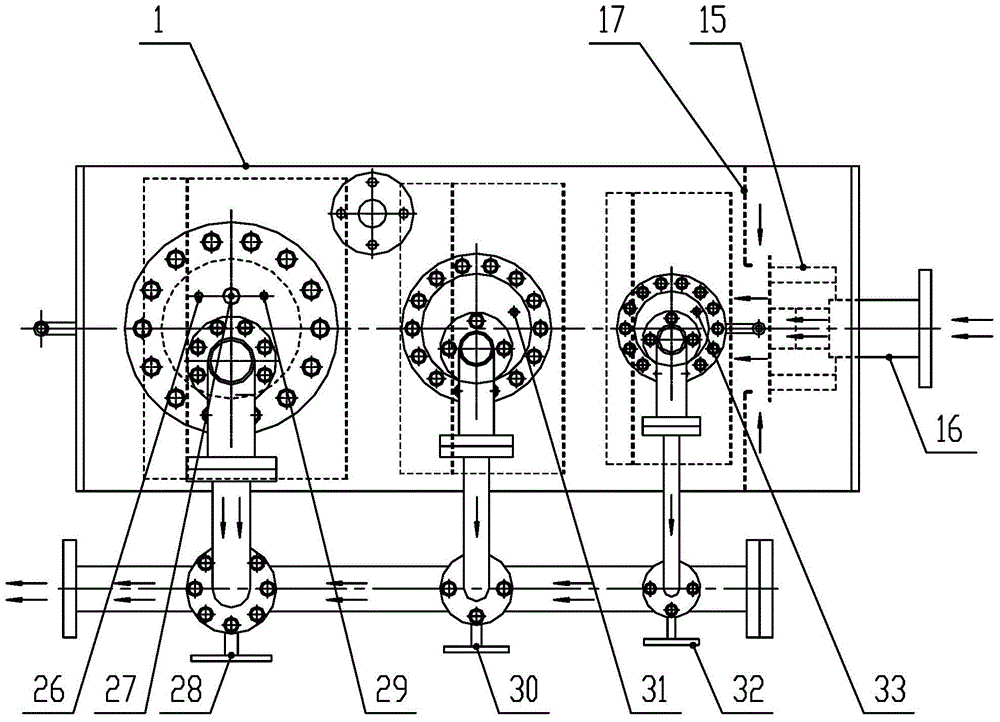

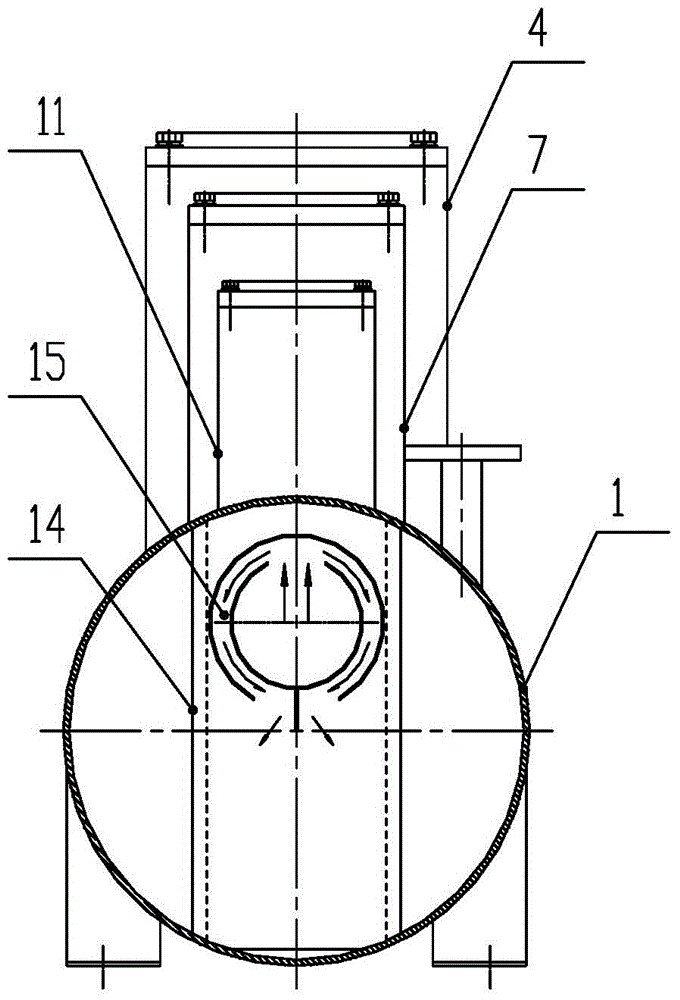

[0043] The present invention will be further explained below in conjunction with the accompanying drawings. Figure 1~4 The arrow in is the flow direction of the oil-gas mixture.

[0044] Such as Figure 1~4 As shown, the cylinder 1 of the present oil and gas separator is provided with a feed pipe 16 for conveying a mixture of oil and gas, a circulating lubricating oil outlet pipe 23 connected with an oil pump, and an exhaust pipe system for discharging gaseous separated materials. A centrifugal degreasing unit 15, a labyrinth degreasing unit, a three-row filter degreasing unit, and an exhaust piping are sequentially arranged between the body 1 from the feed pipe 16 to the exhaust pipe system.

[0045] Such as figure 1 , 2 As shown, one end of the feed pipe 16 is inserted into the first centrifugal degreasing pipe 15a of the centrifugal degreasing unit 15. The oil and gas mixture enters the first centrifugal degreasing pipe 15a from the feed pipe 16, and the first centrifugal degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com