Double row tapered roller bearing and installing structure thereof

A tapered roller bearing and installation structure technology, applied in the field of bearing structure, can solve the problems of unsatisfactory bearing life, difficult installation, low reliability, etc., and achieve the effects of superior performance, lower assembly accuracy requirements, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

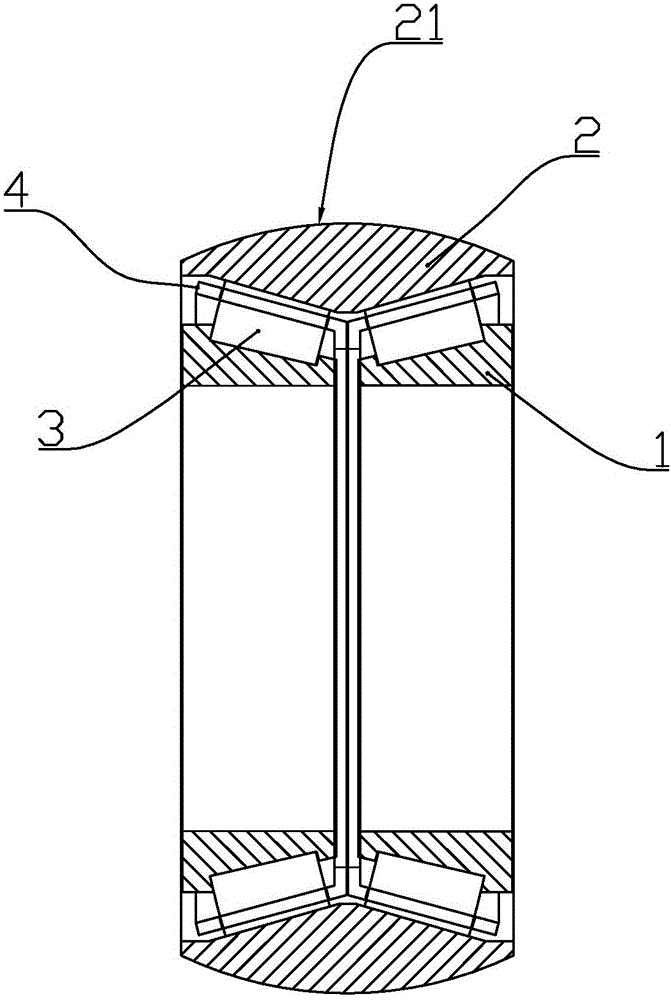

[0014] according to figure 1 As shown, a double-row tapered roller bearing capable of bearing axial and radial combined loads described in this embodiment includes an inner ring 1, an outer ring 2, and two sets of rollers installed between the inner ring and the outer ring. Each group of rollers is respectively installed on a cage 4; the outer wall 21 of the outer ring is a convex spherical surface.

Embodiment 2

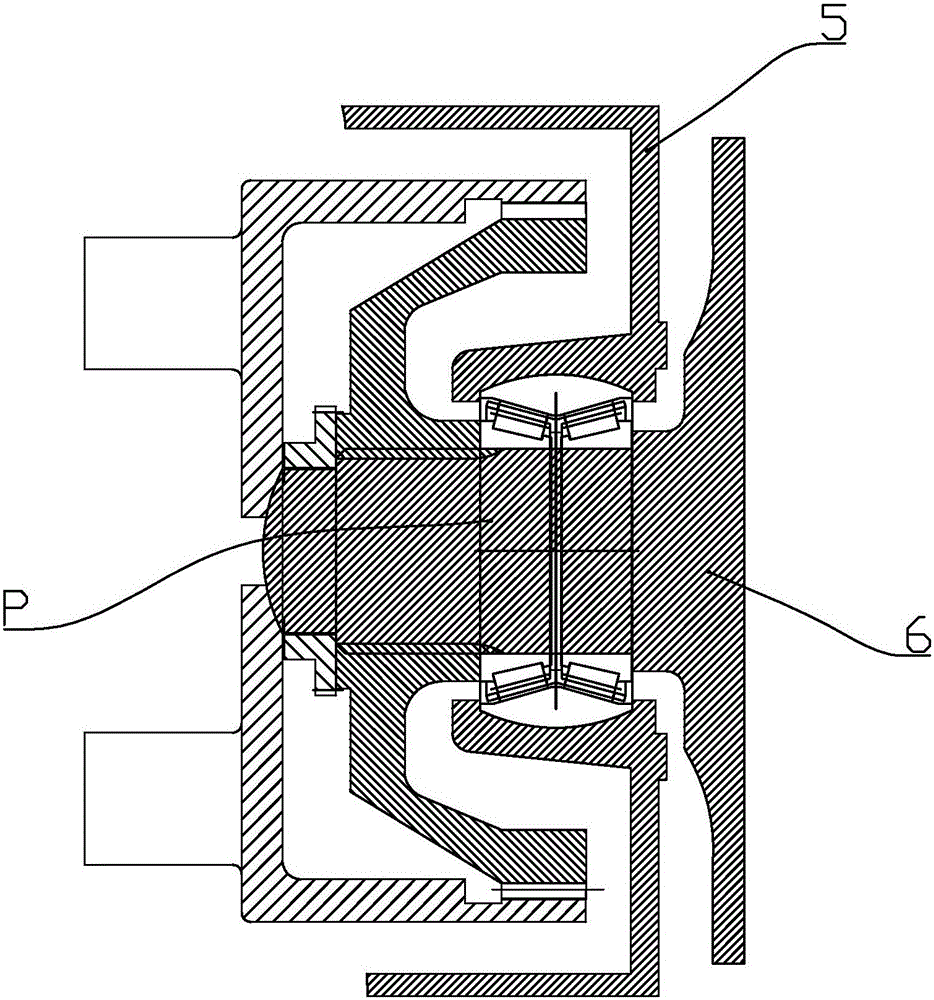

[0016] according to figure 1 and figure 2 As shown, the installation structure of a double-row tapered roller bearing capable of bearing axial and radial combined loads described in this embodiment,

[0017] It includes an organic casing 5, a double-row tapered roller bearing P and an output shaft 6.

[0018] The double-row tapered roller bearing includes an inner ring 1, an outer ring 2, and two sets of rollers 3 installed between the inner ring and the outer ring, and each set of rollers is respectively installed on a cage 4; The outer wall 21 of the outer ring is a convex spherical surface; the casing is formed with an inner concave spherical surface that is slidably connected with the outer wall of the outer ring; the output shaft is connected with the inner ring.

[0019] The outer wall of the outer ring is a convex spherical surface, which is essentially used as the inner ring of the joint bearing and plays a role of self-alignment; the bearing has improved radial and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com