Self-cleaning spiral plate sewage heat exchanger

A technology of spiral heat exchange and spiral plate, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc. Solve the problems of fouling on the surface of the heat exchange plate, unsatisfactory sewage discharge effect, etc., and achieve the effect of self-cleaning, eliminating dirt adhesion and scaling, and realizing the effect of sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

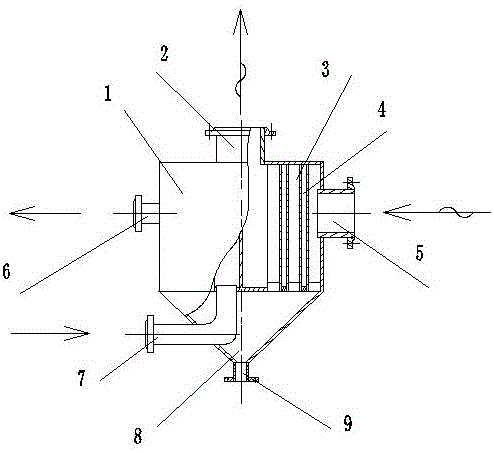

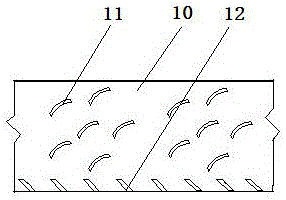

[0013] Depend on figure 1 , figure 2 The shown self-cleaning spiral plate heat exchanger of the present invention is a new type of spiral plate heat exchange equipment designed on the basis of the prior art. It consists of a cylindrical shell 1, a spiral heat exchanger body composed of a wide sewage flow channel 3 and a clean water narrow flow channel 4 formed by two adjacent heat exchange plates winding in parallel multiple turns in the shell 1. The outer spiral plate 10 forming a wide flow channel for sewage heat exchange in the spiral heat exchange body is a plurality of cleaning units formed by arranging and combining convex arc-shaped guide plates 11 on the inner surface, and in the cleaning unit. The lower end of the sewage unit is evenly distributed in a line and is composed of sewage discharge plates 12 arranged at an inclination angle of 45-60° to the horizontal direction. The arc guide plate 11 of the cleaning unit has the same inclination angle, and its inclinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com