High-voltage framework for cation and anion generator

A technology of positive and negative ions and generators, used in transformers, inductors, transformer/inductor components, etc., can solve the problems of easy breakdown, increased production costs, and short coil pin design, and it is not easy to be Breakdown, ensure reliability, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

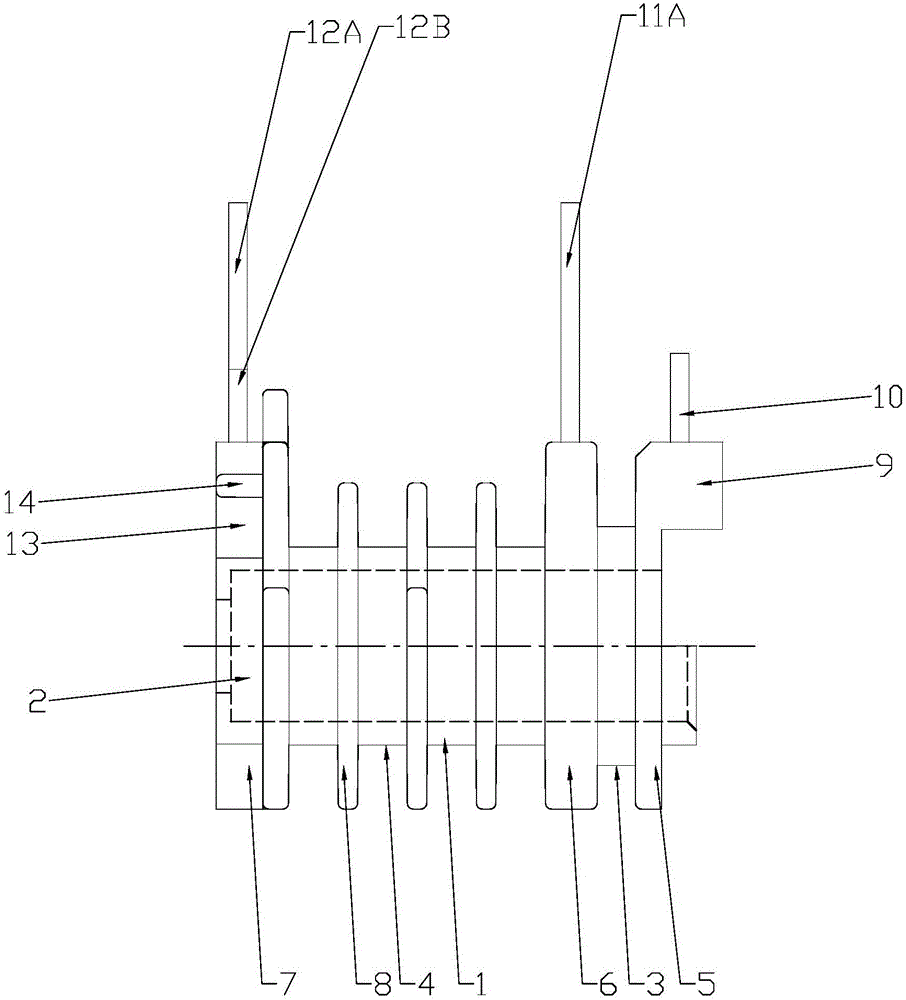

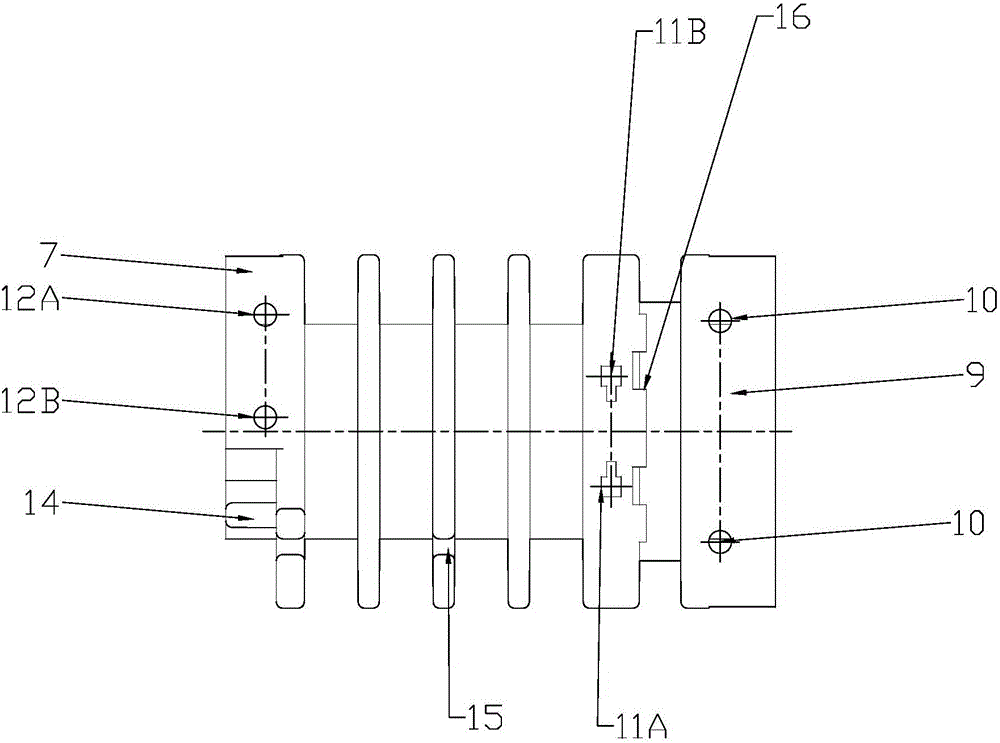

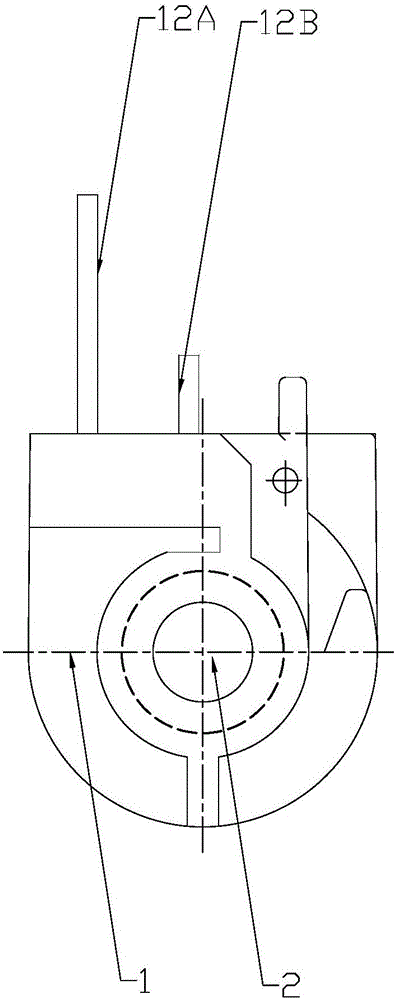

[0017] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0018] Such as Figure 1~3 As shown, the present invention mainly includes an insulating skeleton body 1, and the insulating skeleton body 1 is provided with a primary winding plate 5, a first secondary winding plate 6 and a second secondary winding plate 7 sequentially from one end to the other end, the first secondary winding plate A plurality of secondary winding partitions 8 are arranged between the winding plate 6 and the second secondary winding plate 7, and a primary winding slot 3 is arranged between the primary winding plate 5 and the first secondary winding plate 6, and the first secondary winding The secondary winding slots 4 are preceded by the plate 6 , the second secondary winding plate 7 and a plurality of secondary winding spacers 8 .

[0019] The side wall of the second secondary winding plate 7 is provided with a stress release colum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com