Piezoelectric thin film element, piezoelectric actuator, piezoelectric sensor, hard-disk drive and ink jet printer device

A technology of piezoelectric actuators and piezoelectric films, applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, electrical components, etc., can solve the oxygen deficiency pressure of piezoelectric films Electrical characteristics, influence and other issues, to achieve the effect of reducing leakage current density, improving piezoelectric characteristics, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

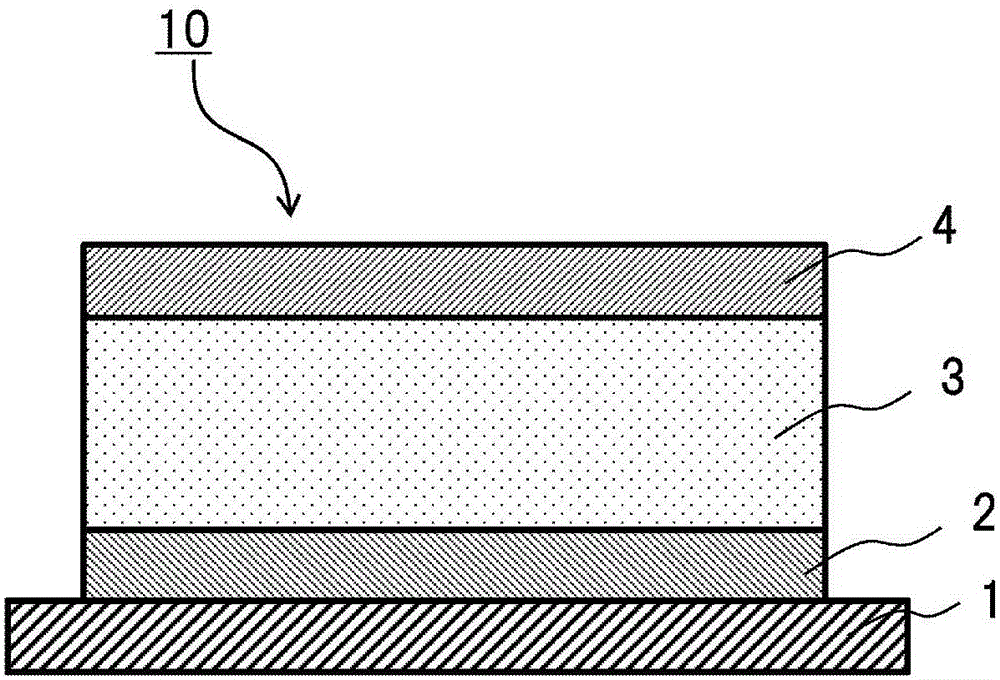

[0050] exist figure 1 The structure of the piezoelectric thin film element 10 of this embodiment is shown in .

[0051] As the substrate 1, a single crystal silicon substrate, a silicon-on-insulator (SOI) substrate, a quartz glass substrate, a compound semiconductor substrate made of GaAs or the like, a sapphire substrate, a metal substrate made of stainless steel or the like, a MgO substrate, SrTiO 3 As the substrate, a single crystal silicon substrate is particularly preferable from the viewpoint of substrate cost and process handling. The thickness of the substrate 1 is usually 10 to 1000 μm.

[0052]A lower electrode layer 2 is formed on a substrate 1 . The lower electrode layer 2 is formed by simultaneous film formation of Pt and the oxide material contained therein, and the film formation conditions in the binary sputtering of the Pt target and the oxide material target or the binary vapor deposition of two materials Thus, fine adjustment of the oxide content in the l...

no. 2 Embodiment approach

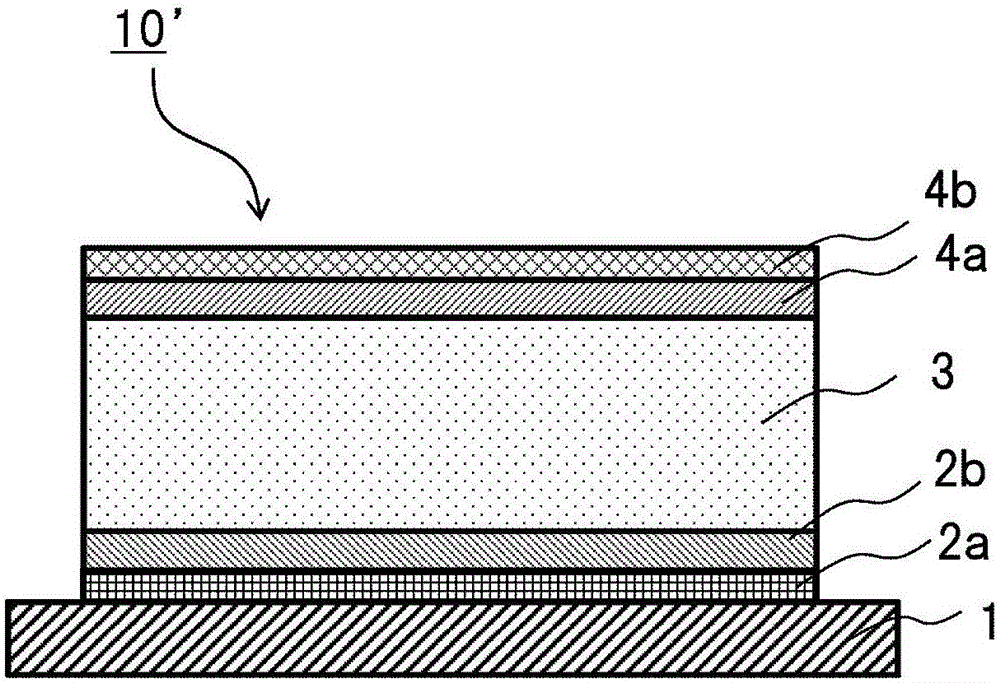

[0060] In the case of improving the piezoelectric characteristics of the piezoelectric thin film element and further improving leakage current suppression, the following configurations can be adopted. exist figure 2 The structure of the piezoelectric thin film element 10' of this embodiment is shown in .

[0061] As the substrate 1, a single crystal silicon substrate, a silicon-on-insulator (SOI) substrate, a quartz glass substrate, a compound semiconductor substrate made of GaAs or the like, a sapphire substrate, a metal substrate made of stainless steel or the like, a MgO substrate, SrTiO 3 As the substrate, a single crystal silicon substrate is particularly preferable from the viewpoint of substrate cost and process handling. The thickness of the substrate 1 is usually 10 to 1000 μm.

[0062] The first lower electrode layer 2 a is formed on the substrate 1 . The first lower electrode layer 2a is formed by simultaneous film formation of Pt and the contained oxide materia...

no. 3 Embodiment approach

[0071] When reducing the resistance value of the piezoelectric thin film element with priority, the following aspects are also applicable. exist figure 2 The structure of the piezoelectric thin film element 10' of this embodiment is shown in .

[0072] As the substrate 1, a single crystal silicon substrate, a silicon-on-insulator (SOI) substrate, a quartz glass substrate, a compound semiconductor substrate made of GaAs or the like, a sapphire substrate, a metal substrate made of stainless steel or the like, a MgO substrate, SrTiO 3 As the substrate, a single crystal silicon substrate is particularly preferable from the viewpoint of substrate cost and process handling. The thickness of the substrate 1 is usually 10 to 1000 μm.

[0073] The first lower electrode layer 2 a is formed on the substrate 1 . The material of the first lower electrode layer 2a is Pt that does not contain oxide materials, and the formation method is sputtering or vapor deposition. The film thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com