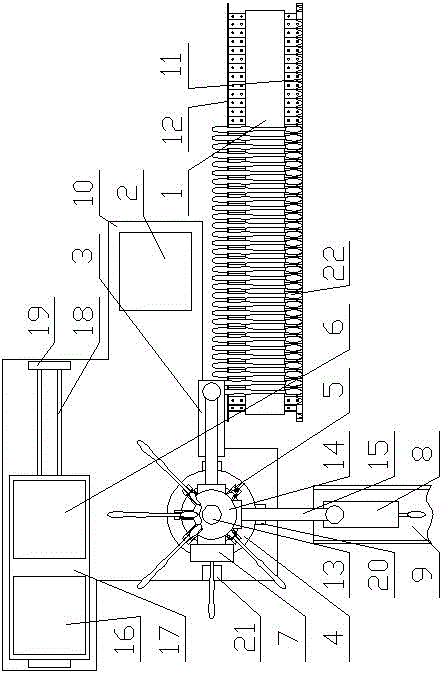

Automatic labeling machine for toothbrush handles

A technology for a toothbrush handle and a marking machine, which is applied to printing machines, rotary printing machines, brushes, etc., can solve the problems of low production efficiency, high production cost, and high defective rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0111] When the present invention is in use, when one end of the marking machine 16 of the slide plate 17 is attached to the limit block 19, that is, the inking device 6 corresponds to the marking station at this moment, and when it is close to the limit block 19 on the side of the marking machine 16 The signal sensor H of the signal sensor H does not get a signal, and the signal sensor G on the limit block 19 near the side of the inking device 6 gets a signal at the same time, then the inking device 6 and the gluing device 3 work, but the marking machine 16 does not work .

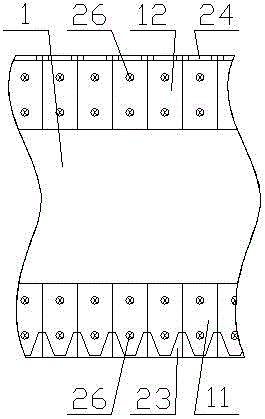

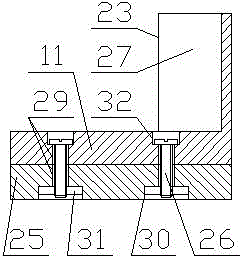

[0112]After the system is started, the motor C drives the conveyor belt 25 to move forward step by step. The operator places the toothbrush 22 on the conveyor belt 25 in sequence. The paint template 36 of the paint block 37 leaves the paint box 34, and then through the action of the piston B45, the paint block 37 is driven to stretch out to the top of the toothbrush handle of the toothbrush 22, and the pi...

Embodiment 2

[0120] When the present invention is in use, when one end of the inking device 6 of the slide plate 17 is attached to the limit block 19, that is, the marking machine 16 corresponds to the marking station at this time, when the limit block 19 on the side of the inking device 6 is close to The signal sensor G of the signal sensor G does not get a signal, and the signal sensor H on the limit block 19 near the side of the marking machine 16 gets a signal at the same time, then the inking device 6 and the gluing device 3 do not work, and the marking machine 16 works .

[0121] After the system is started, the motor C drives the conveyor belt 25 to move forward step by step, and the operator places the toothbrush 22 on the conveyor belt 25 in sequence. The motor A51 of the fetching device A3 drives the rotating base block 49 to rotate until the center line of the rotating base block 49 is in the same vertical plane as the toothbrush 22, and the piston rod D stretches out. The pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com