Small engine layered catalyst article and method of making

A technology of catalysts and products, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., and can solve problems such as poor ability and poor toxicity resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

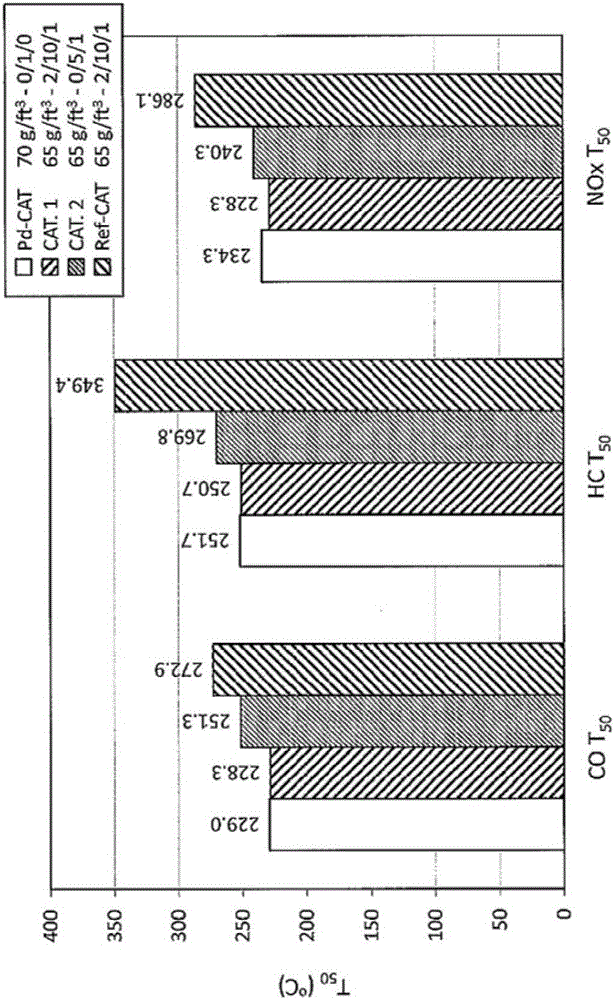

Examples

preparation example Construction

[0052] The preparation of the second catalytic layer can be deposited on the first layer in the same manner as described above for the deposition of the first catalytic layer, using OSC as a support for rhodium and optionally platinum components . An alumina support can also be included in the second catalytic layer, but is not required.

[0053] Before several exemplary embodiments of the invention are described, it is to be understood that the invention is not limited to the details of construction and process steps set forth in the following description. The invention is capable of other embodiments and of being carried out in various ways.

[0054] The following non-limiting examples are intended to illustrate various embodiments of the invention. In each example, the support is cordierite.

Embodiment

[0056] 1. Forming the first catalytic layer

[0057] A portion of the solution of the palladium component and a portion of the solution of the platinum component are mixed with high surface area lanthanum-alumina, and water to form a wet powder and achieve incipient wetness impregnation. Separately, a further part of the solution of the palladium component and a further part of the solution of the platinum component are mixed with refractory lanthanum oxide-alumina, and water to form a wet powder and achieve incipient wetness impregnation. Ceria-zirconia, octanol, acetic acid and zirconium acetate were added and mixed with the Pd / Pt+ support mixture in a planetary mixer (P-mixer). The wet powder preparation was crushed to a particle size of 90% = 5-15 μm. The slurry is coated onto the monolithic support using deposition methods known in the art for depositing catalysts on substrates. After coating, the support with the primer layer and the first catalytic layer was dried and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com