Temperature control system for reagent cabin of biochemical analyzer

A temperature control system, temperature control system technology, applied in the field of medical equipment, can solve the problems of long circulation pipeline, low refrigeration efficiency, low heat conduction efficiency of circulating water, etc., reduce equipment failure rate, suppress scale, etc., and facilitate The effect of troubleshooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

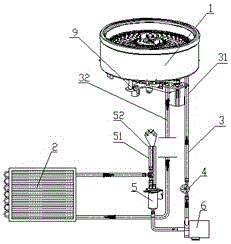

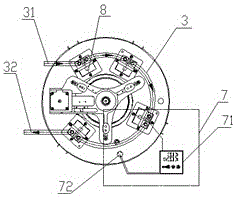

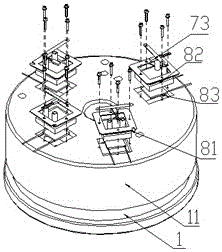

[0027] see Figure 1-Figure 5 , the embodiment of the present invention includes:

[0028] A temperature control system for a reagent chamber of a biochemical instrument, comprising: a refrigeration chamber 1, a refrigeration device 8, a circulation pipeline 3, a radiator 2 and a temperature control system 7, and the number of the refrigeration devices 8 is four groups and is evenly arranged in the refrigeration chamber 1, the refrigerating device 8 includes: a semiconductor cooling chip 83 in contact with the bottom of the cooling chamber 1, a water cooling head 82 arranged above the semiconductor cooling chip 83, and a pressure plate 81 arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com