GW-XZ type linear vibrating screen

A linear vibrating screen, GW-XZ technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of cumbersome tensioning mechanism, accumulated damage of screen box parts, unsatisfactory screen box inclination adjustment mechanism, etc., to achieve The overall structure and component structure are scientific and reasonable, the effect of improving dynamic characteristic parameters and avoiding resonance cumulative damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention is further described:

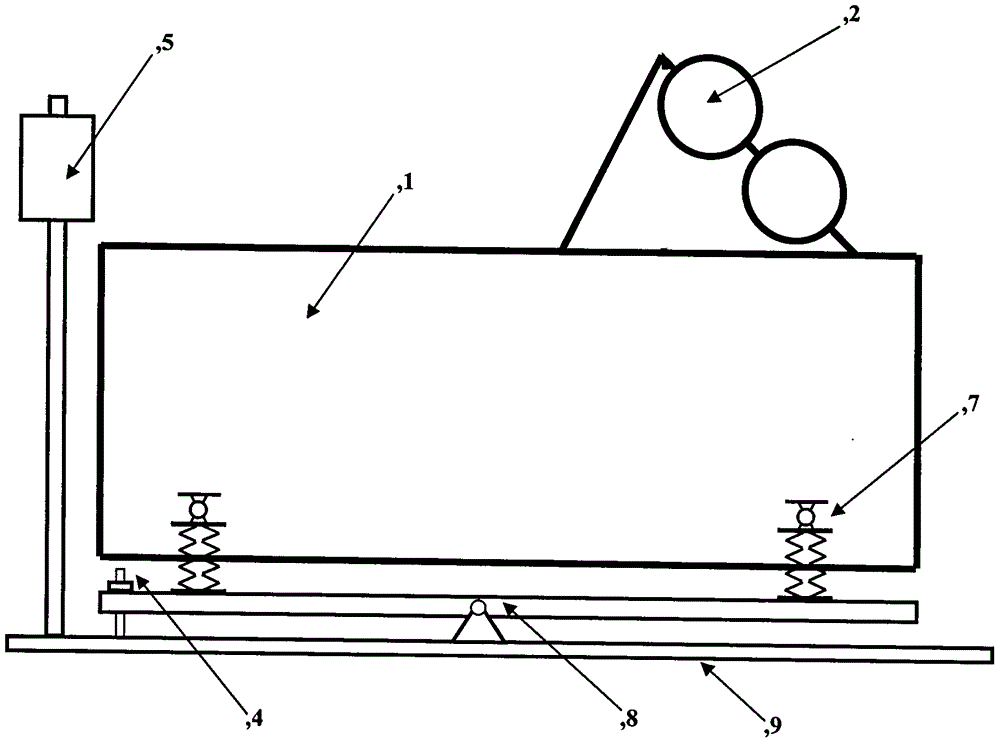

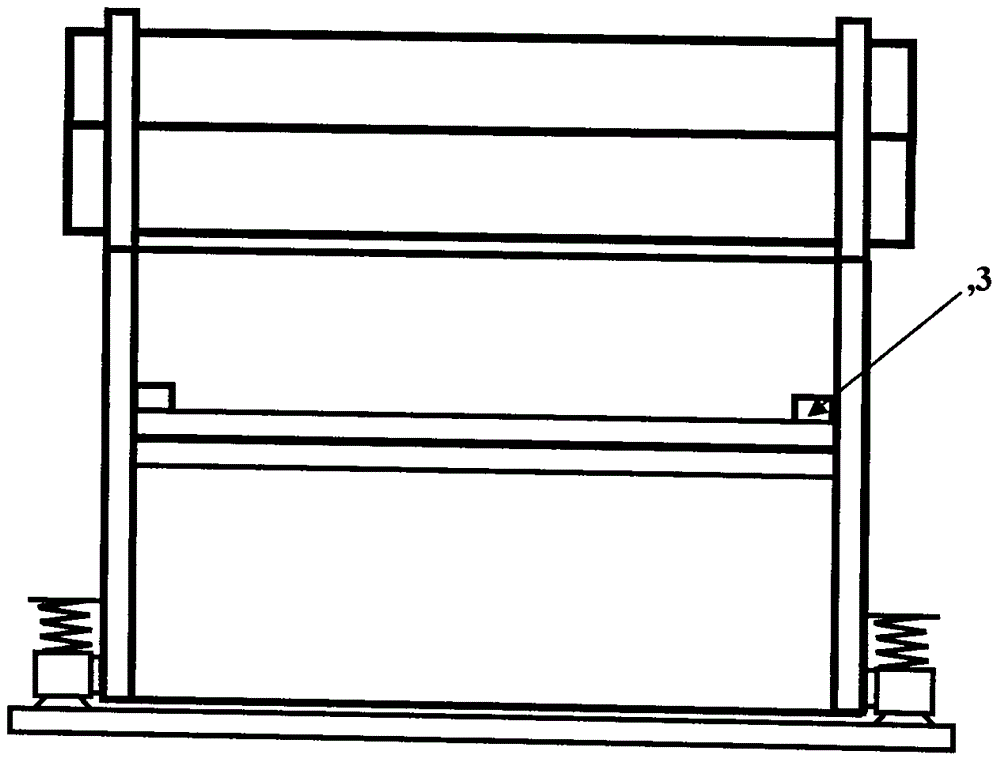

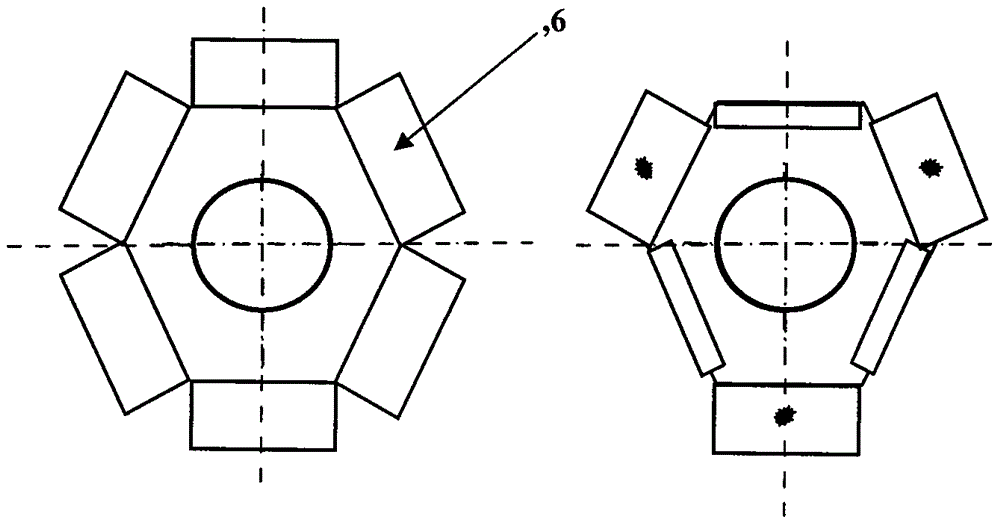

[0026] Such as figure 1 , figure 2 , GW-XZ type linear drilling vibrating screen, consisting of screen box 1, large-span vibration motor based on steel rope coupling 2, gear inclined block type sieve plate pressing mechanism 3, screen box self-weight screw inclination adjustment mechanism 4, with automatic The electrical switch box 5 of the control function, spot fusion electric welding plum blossom steel foil anti-loosening gasket 6, the parallel combination support spring 7 with dumpling support, the screen box support lever 8 with dumpling support and the complete machine base 9 are composed of main components.

[0027] GW-XZ type linear drilling vibrating screen, the screen box 1 is installed on the support lever 8 of the screen box with the support through the parallel combined support spring 7 with the support, and the support lever 8 of the screen box with the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com