High precision control system and method for forging oil press

A control system and high-precision technology, applied to the driving device of the forging press, etc., can solve the problems of slow system response, measurement of forging size deviation, and failure to consider frame deformation, etc., to achieve high control accuracy and fast system response. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

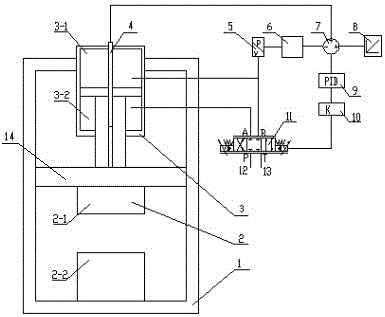

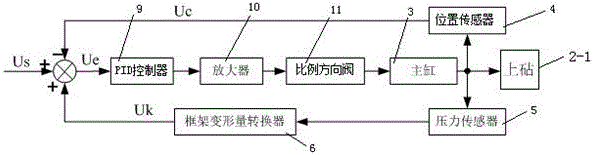

Embodiment 1

[0024] In order to solve the problem that the existing forging hydraulic press does not take into account the deformation of the frame when it is pressurized, which leads to deviations in the actual measurement of the forging size and the slow response of the system, such as figure 1 As shown, this embodiment provides a high-precision control system for forging hydraulic presses, including a press frame 1 and a movable beam 14 moving on the press frame 1. An anvil 2 is installed on the lower surface of the movable beam 14, and the upper surface passes through the plunger. Connected with a master cylinder 3, the master cylinder 3 is provided with a position sensor 4, the position sensor 4 is electrically connected to the adder-subtractor 7, and the adder-subtractor 7 is electrically connected to the input device 8, and the master cylinder 3 is connected to the proportional directional valve through a pipeline 11. The proportional directional valve 11 is electrically connected to...

Embodiment 2

[0028] On the basis of Embodiment 1, the inner chamber of the master cylinder 3 is divided into a master cylinder large chamber 3-1 and a master cylinder small chamber 3-2, and the master cylinder large chamber 3-1 is connected to the B port of the proportional directional valve 11, The small cavity 3-2 of the master cylinder is connected with the A port of the proportional directional valve 11, the P port of the proportional directional valve 11 is connected with the oil supply pipe 12, and the T port of the proportional directional valve 11 is connected with the oil return pipe 13.

[0029] Described type anvil 2 is made up of upper anvil 2-1 and lower anvil 2-2, and upper anvil 2-1 is fixed on the lower surface of movable beam 14, and lower anvil 2-2 is fixed on the lower beam of press frame 1.

[0030] It should be noted that, if figure 1 As shown, the lower anvil 2-2 is fixed on the press frame 1, the main cylinder 3 is fixed on the press frame 1, and when the main cylind...

Embodiment 3

[0032] On the basis of Embodiment 1, preferably, the input device 8 is a touch screen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com