Complete set of equipment applied to full-automatic laser engraving of paper

A laser engraving and fully automated technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as stoppage and incomplete automatic production process, and achieve the goals of reduced idle time, increased output, and high processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

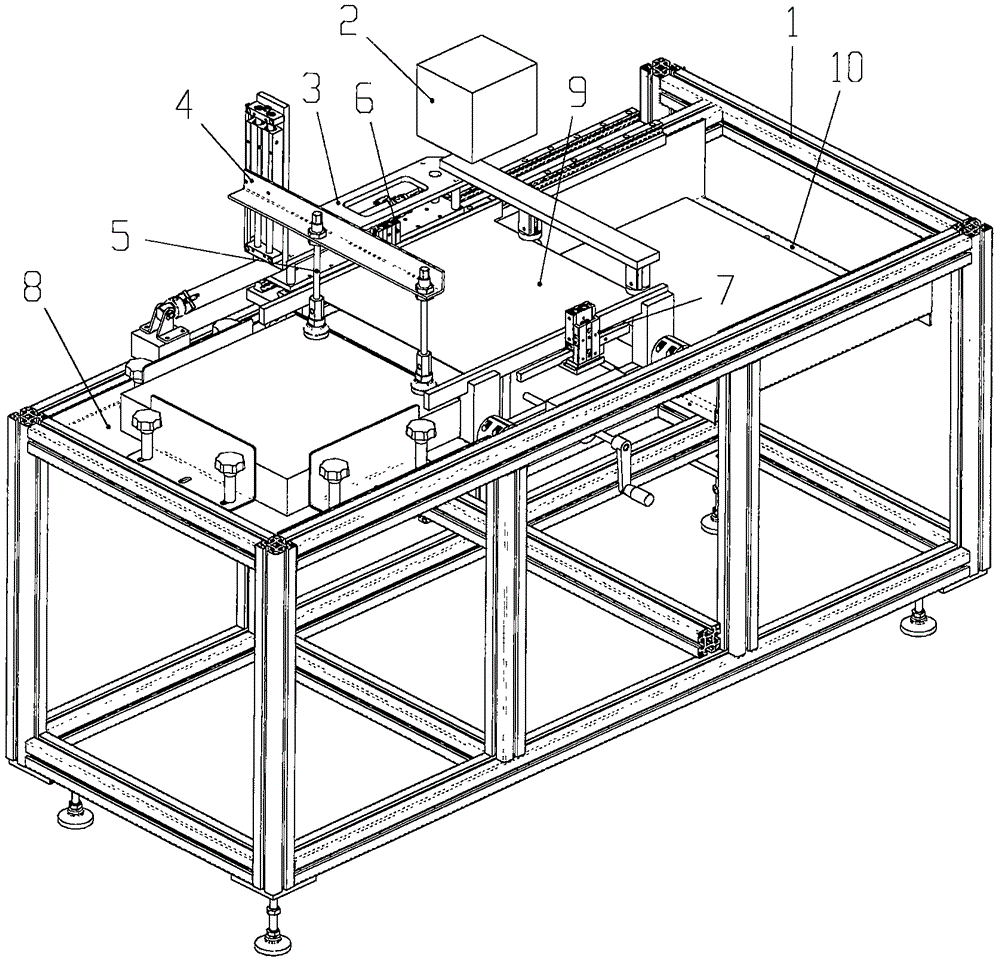

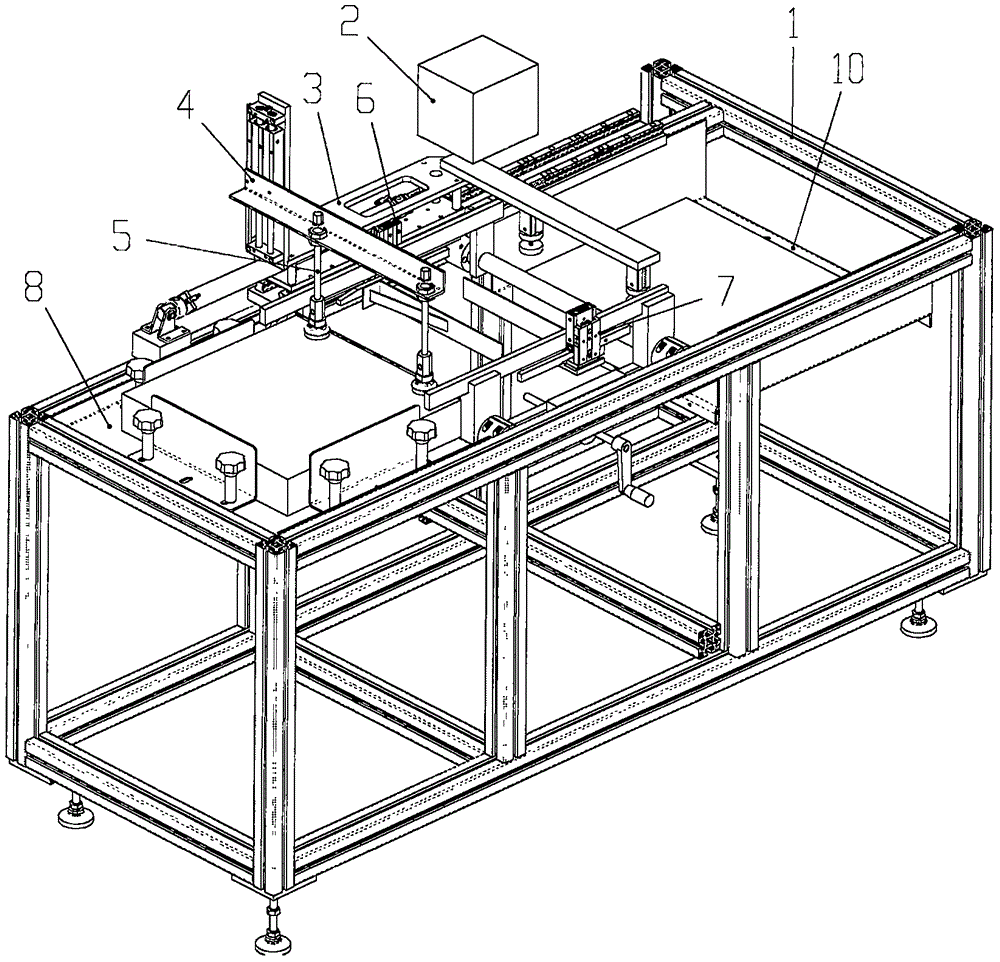

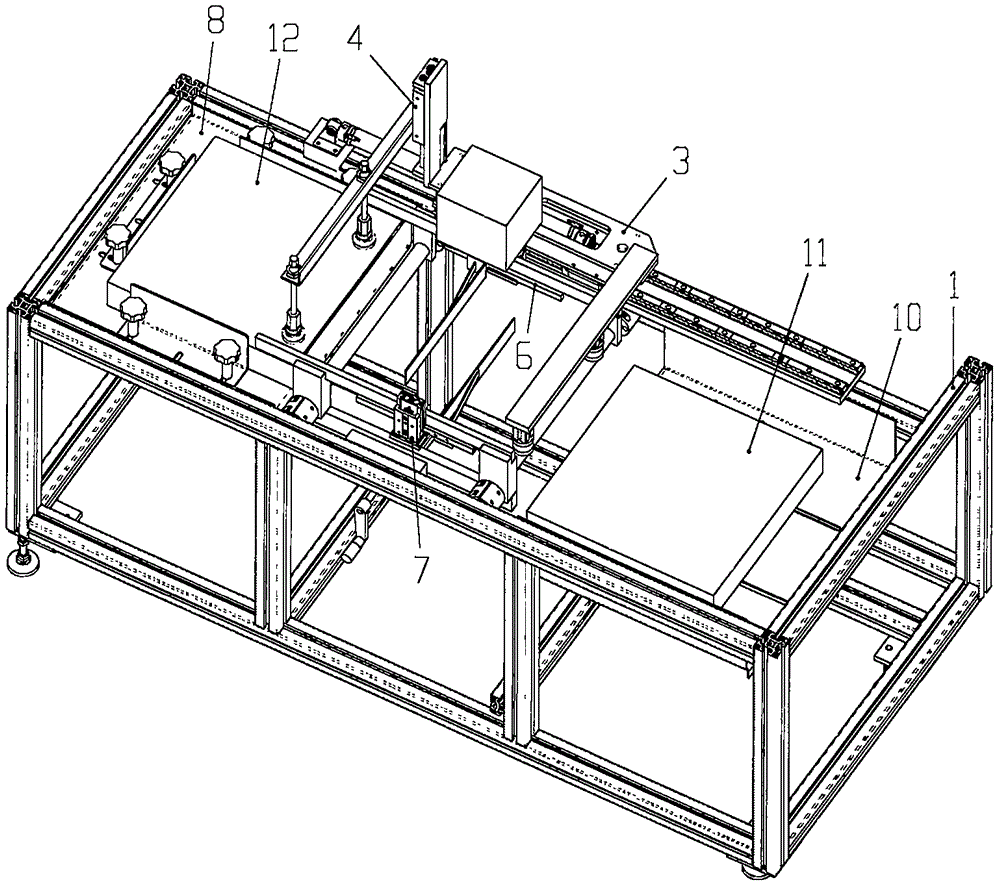

[0028] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention provides a complete set of fully automatic paper laser engraving equipment. The papers to be engraved are arranged in piles on the preparation table. The vacuum suction cup picks up a piece of paper and enters the engraving area. Multiple positions are fixed, the laser head performs high-speed laser engraving on the paper, and after the engraving is completed, the gripper transports the paper to the collection area; the paper conveying process is automatic, and the whole process does not require manual intervention, which realizes automatic operation; the laser marking machine Realize high-speed engraving on paper with high production efficiency.

[0029] figure 1 , 2 , 3 is a structural schematic diagram of a complete set of fully automated paper laser engraving equipment of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com