Self-lifting semi-submersible type underwater working platform

A working platform and semi-submersible technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as high requirements for ballast water systems, complicated load adjustment operations, and high requirements for operators, and achieve simple structure, Low cost, high buoyancy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended Figures 1 to 4 The working platform for self-elevating and semi-submersible launching provided by the present invention is described in detail.

[0032] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In the embodiments, parts of the same configuration are given the same reference numerals and descriptions are omitted.

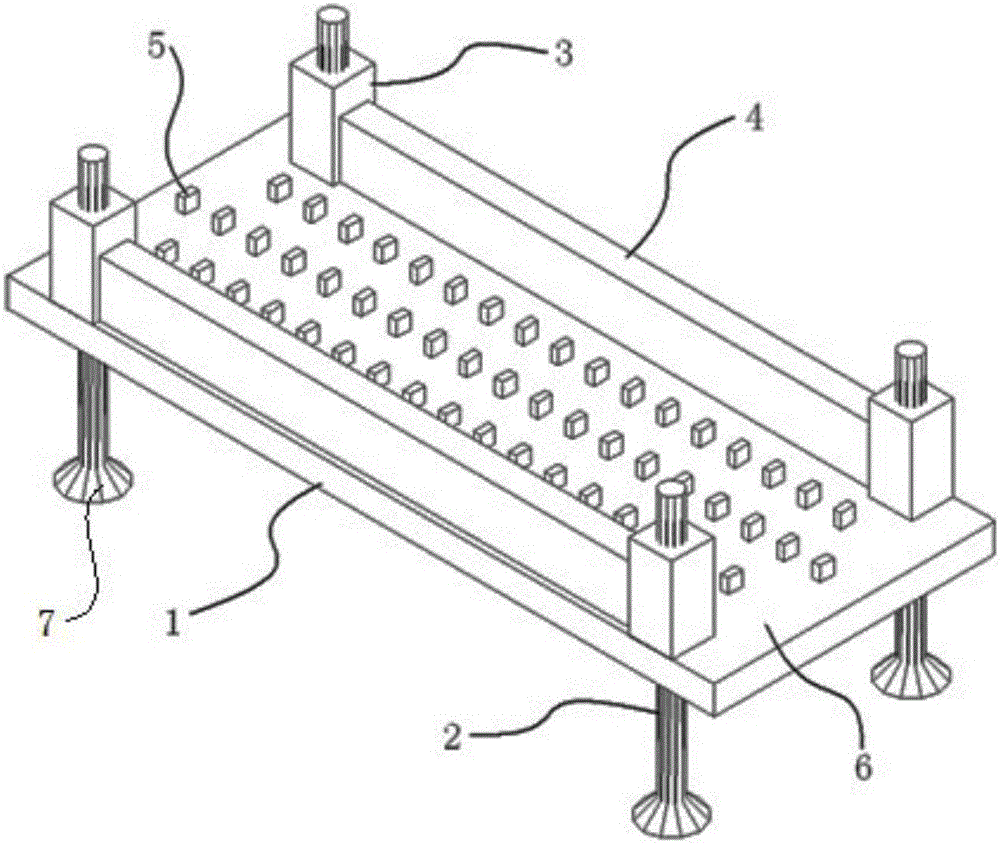

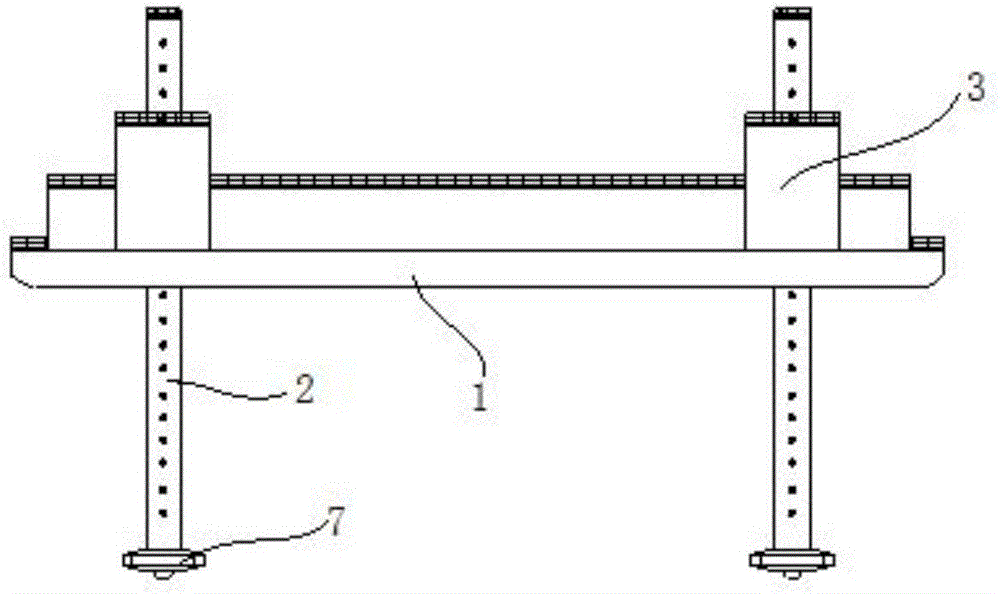

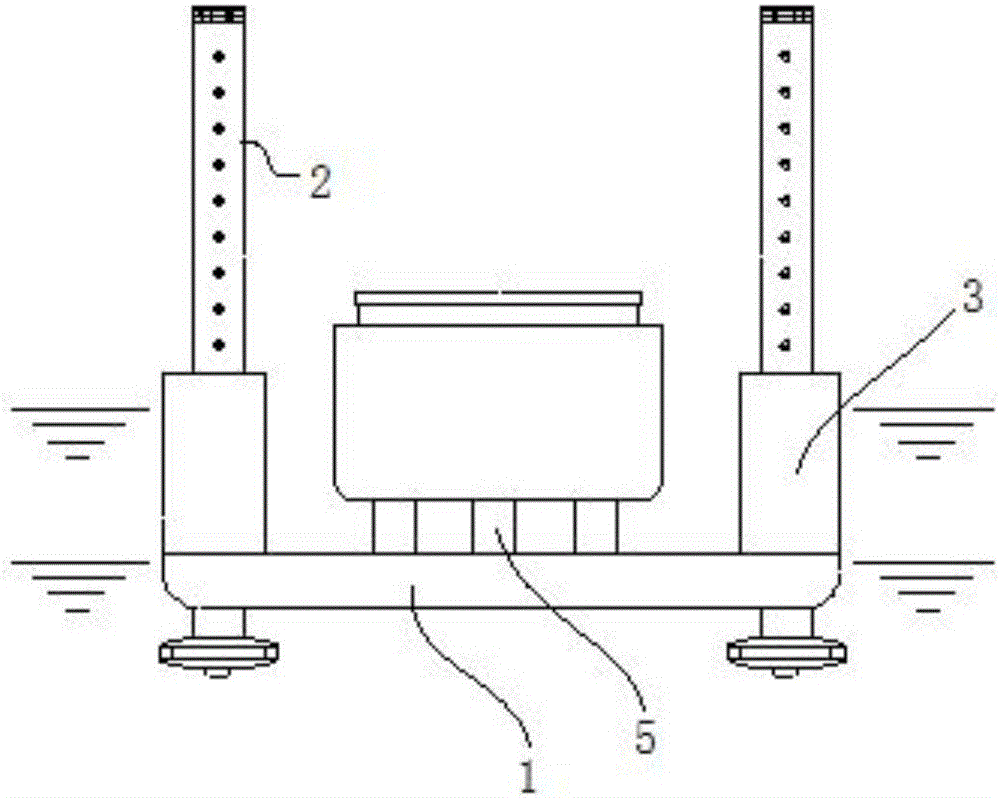

[0033] figure 1 It is the overall elevation view of the working platform of self-elevating semi-submersible launching in the embodiment of the present invention, figure 2 It is the front view of the working platform of self-elevating semi-submersible launching in the embodiment of the present invention, as figure 1 and figure 2 As shown in , the working platform for self-elevating semi-submersible launching inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com