Belt conveyor system for rectangular shield tunneling machine and application and method for belt conveyor system for rectangular shield tunneling machine

A belt conveying and shield machine technology, applied in the direction of mechanical conveyors, conveyors, conveyor objects, etc., can solve the problems of low transportation efficiency and affect the construction of rectangular shields, and achieve improved transportation efficiency, simple structure, and low manufacturing costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that the following examples are only used to illustrate the present invention, not to limit the scope of application of the present invention.

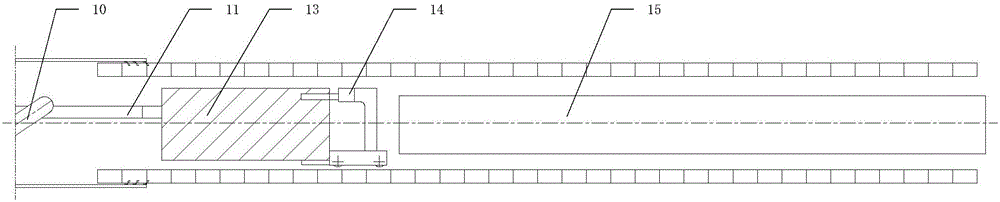

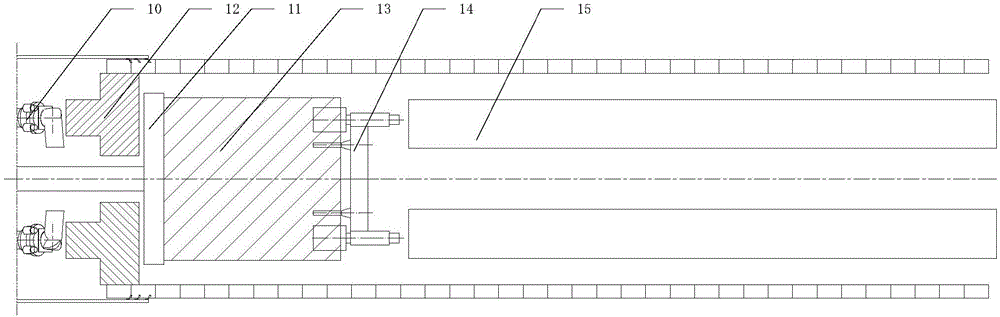

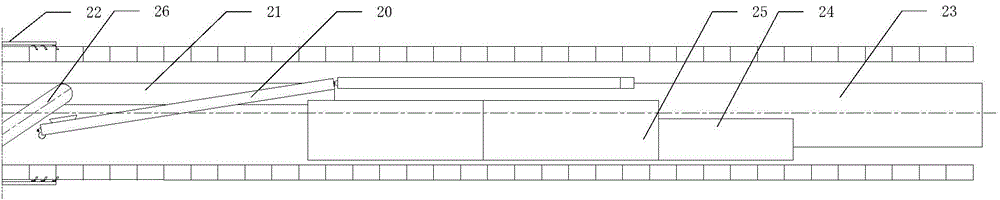

[0046] Please refer to Figure 4 , Figure 5 and Figure 6 , a rectangular shield machine, including a shell 30, a lining 39 installed inside the shell 30, a screw soil dumper 31, a central beam 32, a piece feeding machine 33 and a juxtaposed trolley 34, and a segment assembly machine The working area 35 also includes a belt conveying system for the rectangular shield machine, which is used to transport the muck outward during the propulsion process of the rectangular shield machine. The belt conveying system for the rectangular shield machine includes a first-stage belt conveyor 42, a second stage belt conveyor, lifting mechanism and axial movement mechanism, and the muck discharged by the screw dumper 31 is tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com