Electric heating bucket detecting and carrying workstation

An electric hot tub and workstation technology, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of heavy workload, affecting product accuracy, low efficiency, etc., and achieve the effect of saving detection costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

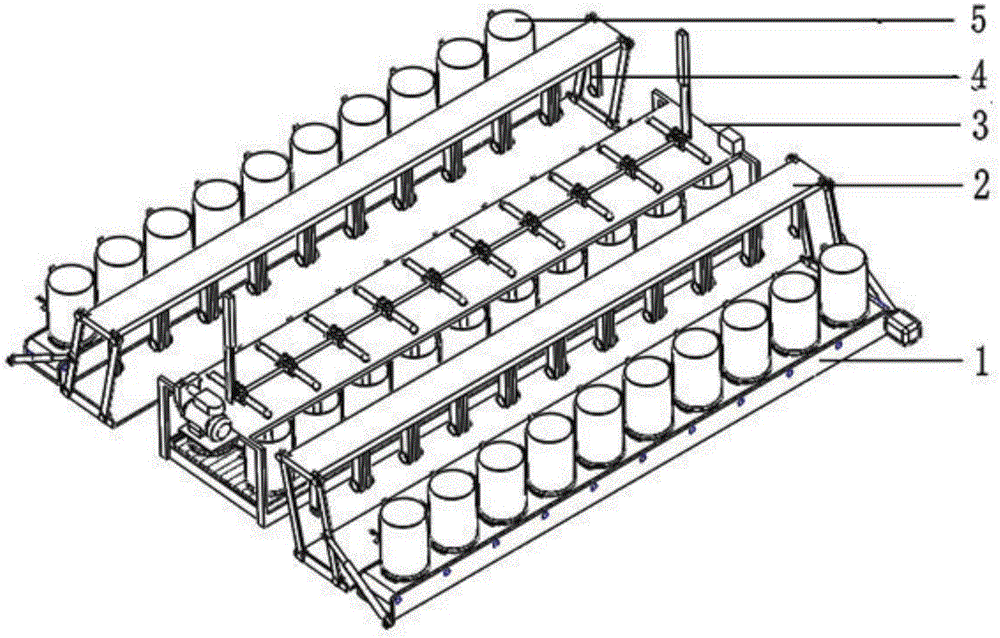

[0020] Embodiment: An electric hot water barrel detection and handling workstation.

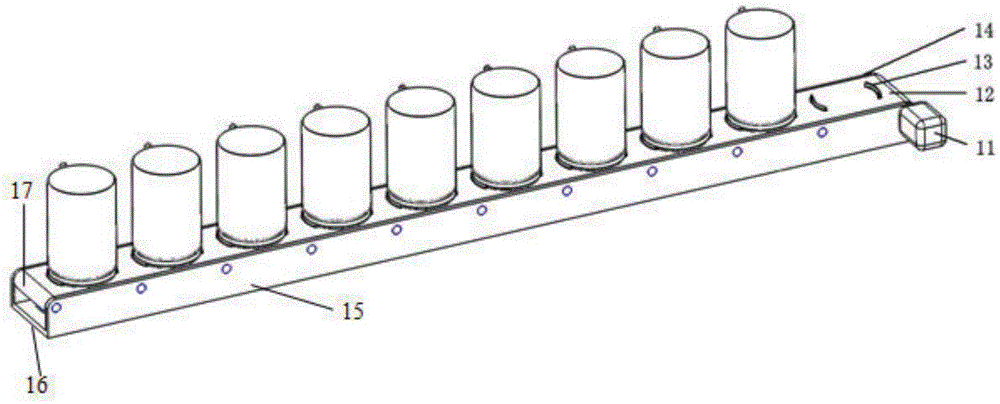

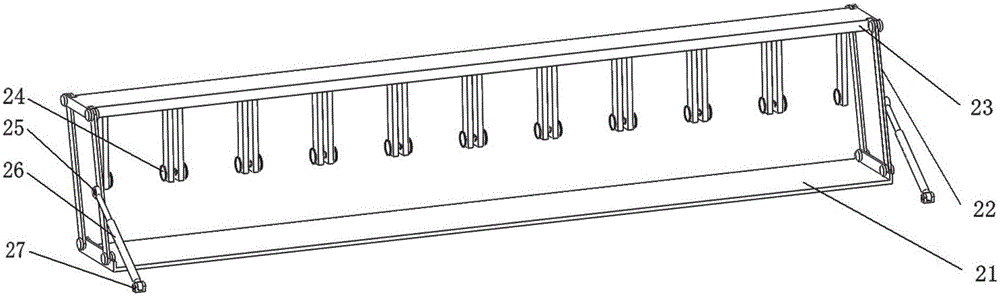

[0021] refer to Figure 1 to Figure 4 As shown in the figure, an electric hot water bucket detection and handling workstation includes:

[0022] Feeding and conveying system 1, said feeding and conveying system 1 includes a "U"-shaped support frame 14 welded by two symmetrically arranged side plates 15 and a bottom plate 16, and the upper end of said support frame 14 is along the length of support frame 14 A plurality of rollers 17 arranged side by side at intervals are installed in the direction, and a transverse conveyor belt 12 is sleeved between the rollers 17. The upper surface of the transverse conveyor belt 12 is arranged with a plurality of arc-shaped electric water bucket positioning blocks 13 side by side and at intervals along the length direction of the conveyor belt. The end of the side plate 15 of the support frame 14 is equipped with a driving motor 11 that can drive the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com