Environment-friendly packaging bag and preparation method thereof

A packaging bag, environmental protection technology, applied in the field of packaging bags, can solve the problems of environmental pollution, packaging bag opening is not easy to tear, packaging bags are not easy to recycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

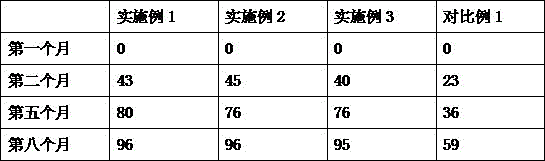

Embodiment 1

[0015] Environmentally friendly packaging bags, including the following raw materials in parts by weight: 40 parts of polyethylene, 60 parts of starch, 50 parts of reed pulp, 75 parts of alumina, 30 parts of zircon sand, 80 parts of methyl ethyl ketoxime, and 50 parts of barite powder parts, 30 parts of bisphenol A epoxy acrylate, and 50 parts of fiber brucite.

[0016] The preparation method of the above-mentioned environment-friendly packaging bag comprises the following steps: mixing polyethylene, starch, reed pulp, aluminum oxide, zircon sand, methyl ethyl ketone oxime, barite powder, bisphenol A epoxy acrylate with a high-speed mixer , The fiber brucite is mixed evenly, the mixing time is 60-100min, the rotating speed is 300-350rpm, and then blow molding with a blow molding machine.

Embodiment 2

[0018] Environmental packaging bag, including the following raw materials in parts by weight: 10 parts of polyethylene, 40 parts of starch, 20 parts of reed pulp, 70 parts of alumina, 10 parts of zircon sand, 20 parts of methyl ethyl ketoxime, 30 parts of barite powder 20 parts, 20 parts of bisphenol A epoxy acrylate, 10 parts of fiber brucite.

[0019] The preparation method of the above-mentioned environment-friendly packaging bag comprises the following steps: mixing polyethylene, starch, reed pulp, aluminum oxide, zircon sand, methyl ethyl ketone oxime, barite powder, bisphenol A epoxy acrylate with a high-speed mixer , The fiber brucite is mixed evenly, the mixing time is 60-100min, the rotating speed is 300-350rpm, and then blow molding with a blow molding machine.

Embodiment 3

[0021] Environmentally friendly packaging bags, including the following raw materials in parts by weight: 60 parts of polyethylene, 100 parts of starch, 80 parts of reed pulp, 80 parts of alumina, 50 parts of zircon sand, 100 parts of methyl ethyl ketone oxime, 90 parts of barite powder Parts, 50 parts of bisphenol A epoxy acrylate, 80 parts of fiber brucite.

[0022] The preparation method of the above-mentioned environment-friendly packaging bag comprises the following steps: mixing polyethylene, starch, reed pulp, aluminum oxide, zircon sand, methyl ethyl ketone oxime, barite powder, bisphenol A epoxy acrylate with a high-speed mixer , The fiber brucite is mixed evenly, the mixing time is 60-100min, the rotating speed is 300-350rpm, and then blow molding with a blow molding machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com