Long-carbon-chain nylon pipe and preparation method thereof

A long carbon chain and nylon tube technology, applied in the field of long carbon chain nylon tube material and its preparation, can solve the problem of oil resistance, zinc chloride resistance not meeting the requirements, low temperature resistance not reaching minus 40°C, delivery Long cycle and other problems, to achieve good resistance to zinc chloride solution, good heat and oxygen aging resistance, and good light aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

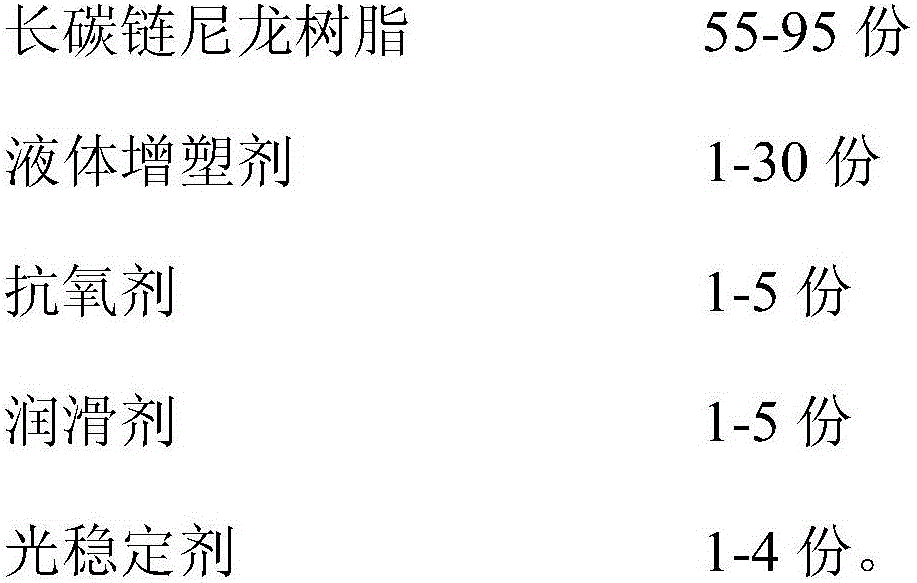

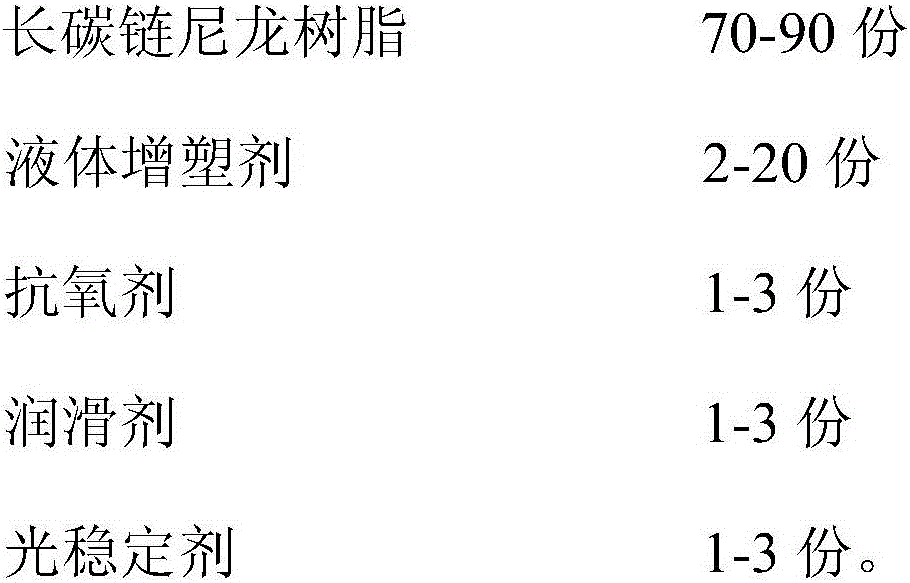

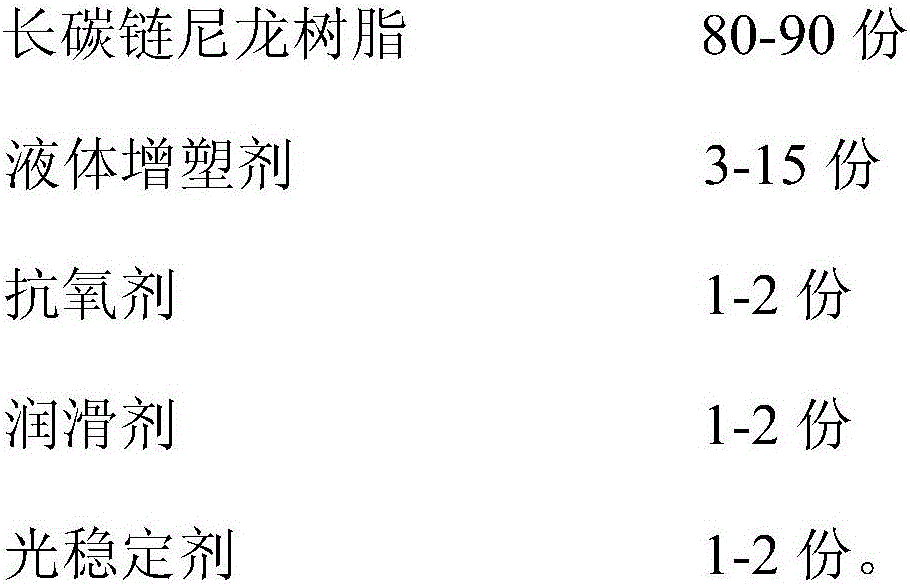

Method used

Image

Examples

Embodiment 1

[0031] A long carbon chain nylon hose material, the raw materials include the following parts by weight: nylon 1012 resin: 85 parts, benzenesulfonylbutylamine: 15 parts, and a blend of antioxidants 1098 and 168 in a mass ratio of 1:1 : 1 part, calcium stearate: 1 part, light stabilizer 622: 1 part;

[0032] A method for preparing long carbon chain nylon pipe material, comprising the following steps:

[0033] 1) Mixing, add nylon 1012 resin, 1098, 168 blend according to the mass ratio of 1:1, calcium stearate and light stabilizer 622 into the high mixer, and blend for 3 minutes at room temperature to obtain a uniformly mixed material ;

[0034] 2) Extrusion and granulation, add the mixed materials in step 1) into the twin-screw extruder, add benzenesulfonylbutylamine through the liquid metering pump, carry out traction and cooling, blow dry and granulate, each area of the twin-screw extruder The temperature setting is: the temperature of the first zone of the twin-screw ext...

Embodiment 2

[0045] A long carbon chain nylon hose material, the raw materials include the following parts by weight: nylon 1212 resin: 55 parts, benzenesulfonamide: 1 part, and a blend of antioxidants 1098 and 168 in a mass ratio of 1:1 : 1 part, calcium stearate: 1 part, light stabilizer 622: 1 part;

[0046] A method for preparing long carbon chain nylon pipe material, comprising the following steps:

[0047] 1) Mixing, add nylon 1012 resin, antioxidant 1098, 168 blend according to 1:1 mass ratio, calcium stearate and light stabilizer 622 into the high-speed mixer, and blend at room temperature for 3 minutes to obtain a uniform mixture materials;

[0048] 2) Extrusion and granulation, add the mixed materials in step 1) into the twin-screw extruder, add benzenesulfonylbutylamine through the liquid metering pump, carry out traction and cooling, blow dry and granulate, each area of the twin-screw extruder The temperature setting is: the temperature of the first zone of the twin-screw e...

Embodiment 3

[0050] A long carbon chain nylon hose material, the raw materials include the following parts by weight: nylon 1012 resin: 75 parts, benzenesulfonylbutylamine: 15 parts, and a blend of antioxidants 1098 and 168 in a mass ratio of 1:1 : 3 parts, calcium stearate: 3 parts, light stabilizer 622: 2 parts;

[0051] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com