Method of repeatedly using seed crystals to prepare monocrystalline high-temperature alloy

A technology of superalloy and seed crystal, applied in the field of preparation of single crystal superalloy, can solve the problems of failure of single crystal orientation control, miscellaneous crystal, unreusable seed crystal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment is a method of repeatedly using seed crystals to prepare a single crystal superalloy test rod having a [001] orientation deviated from the axial direction by an angle of α, and the number of superalloy test rods to be prepared is multiple. The number of superalloy test rods to be prepared in this embodiment is 2, and the [001] orientation of the seed crystal in this embodiment deviates from the axial direction by 0 degrees.

[0034] The concrete steps of this embodiment are as follows:

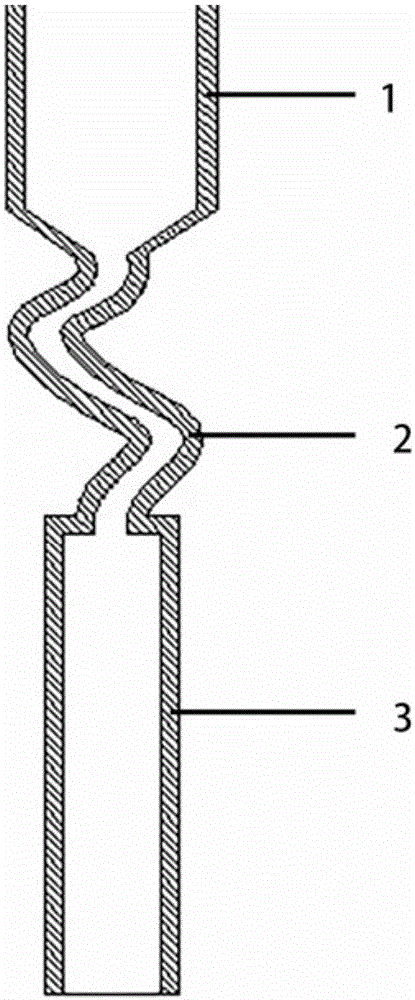

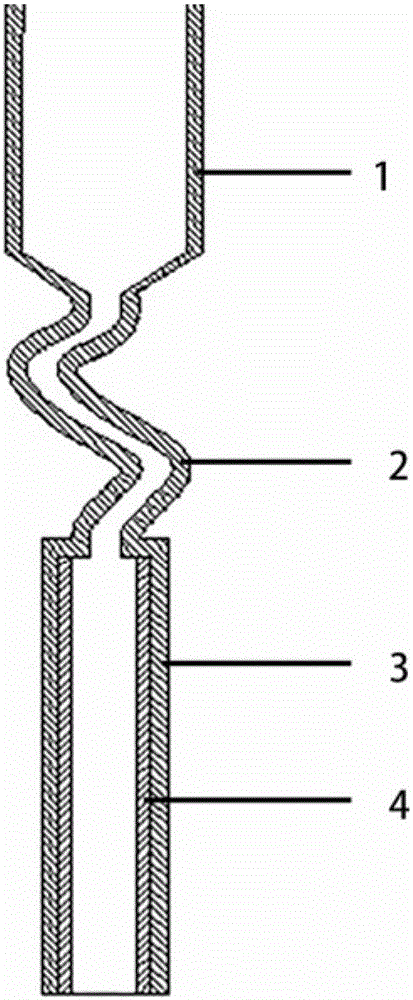

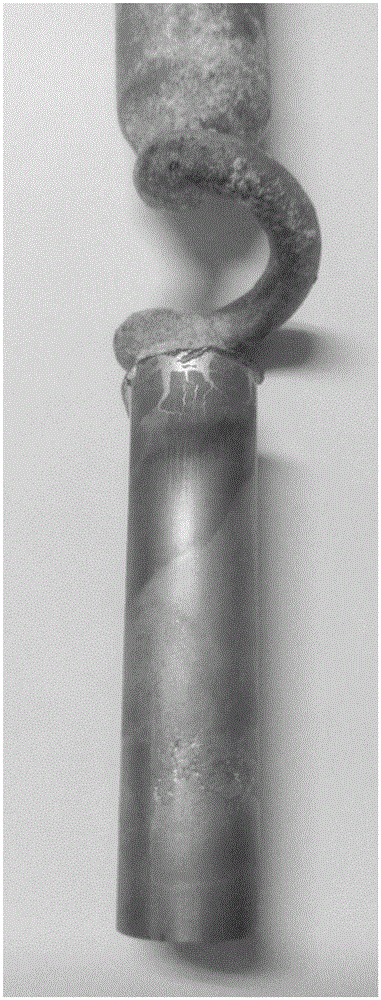

[0035] The first step is to make a mold shell for pre-embedding the corundum tube in the seeding section. The mold shell is composed of a casting segment 1, a crystal selection segment 2 and a seeding segment 3, and one end of the crystal selection segment 2 is connected to one end of the casting segment 1, and the other end of the crystal selection segment 2 is connected to the seeding segment 3 one end of the connection. The corundum tube 4 is placed in the seeding seg...

Embodiment 2

[0045] This embodiment is a method of repeatedly using seed crystals to prepare a single crystal superalloy test rod having a [001] orientation deviated from the axial direction by an angle of α, and the number of superalloy test rods to be prepared is multiple. The number of superalloy test rods to be prepared in this embodiment is 4, and the [001] orientation of the seed crystal deviates from the axial direction by 4 degrees in this embodiment.

[0046] The concrete steps of this embodiment are as follows:

[0047] The first step is to make a mold shell for pre-embedding the corundum tube in the seeding section. The mold shell is composed of a casting segment 1, a crystal selection segment 2 and a seeding segment 3, and one end of the crystal selection segment 2 is connected to one end of the casting segment 1, and the other end of the crystal selection segment 2 is connected to the seeding segment 3 one end of the connection. The corundum tube 4 is placed in the seeding s...

Embodiment 3

[0059] This embodiment is a method of repeatedly using seed crystals to prepare a single crystal superalloy test rod having a [001] orientation deviated from the axial direction by an angle of α, and the number of superalloy test rods to be prepared is multiple. The number of superalloy test bars to be prepared in this embodiment is 8, and the [001] orientation of the seed crystal deviates from the axial direction by 7 degrees in this embodiment.

[0060] The concrete steps of this embodiment are as follows:

[0061] The first step is to make a mold shell for pre-embedding the corundum tube in the seeding section. The mold shell is composed of a casting segment 1, a crystal selection segment 2 and a seeding segment 3, and one end of the crystal selection segment 2 is connected to one end of the casting segment 1, and the other end of the crystal selection segment 2 is connected to the seeding segment 3 one end of the connection. The corundum tube 4 is placed in the seeding s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com