A tidal level adaptive floating pendulum wave power generation system

A power generation system, self-adaptive technology, applied in the direction of ocean energy power generation, engine function, engine components, etc., can solve the problems of not considering the influence of the wave absorption efficiency of the floating body, changing the attitude, and not having it, so as to reduce the probability of being damaged, Optimize the appearance design and avoid the effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

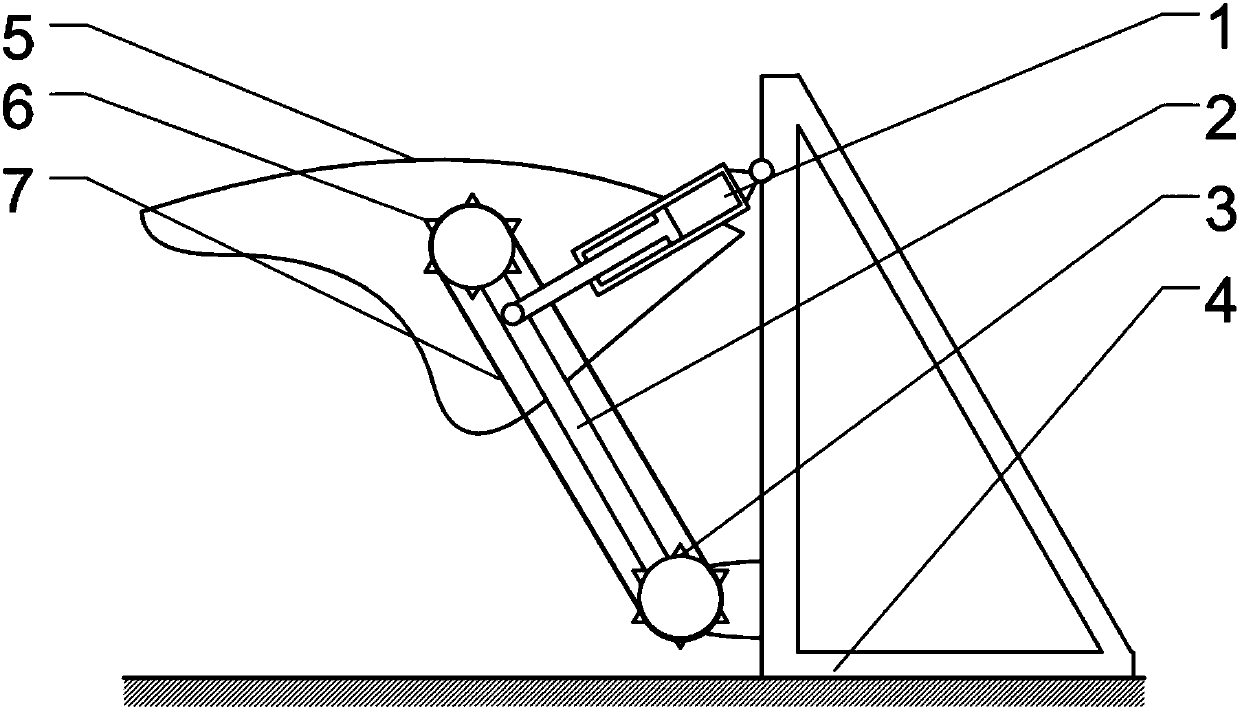

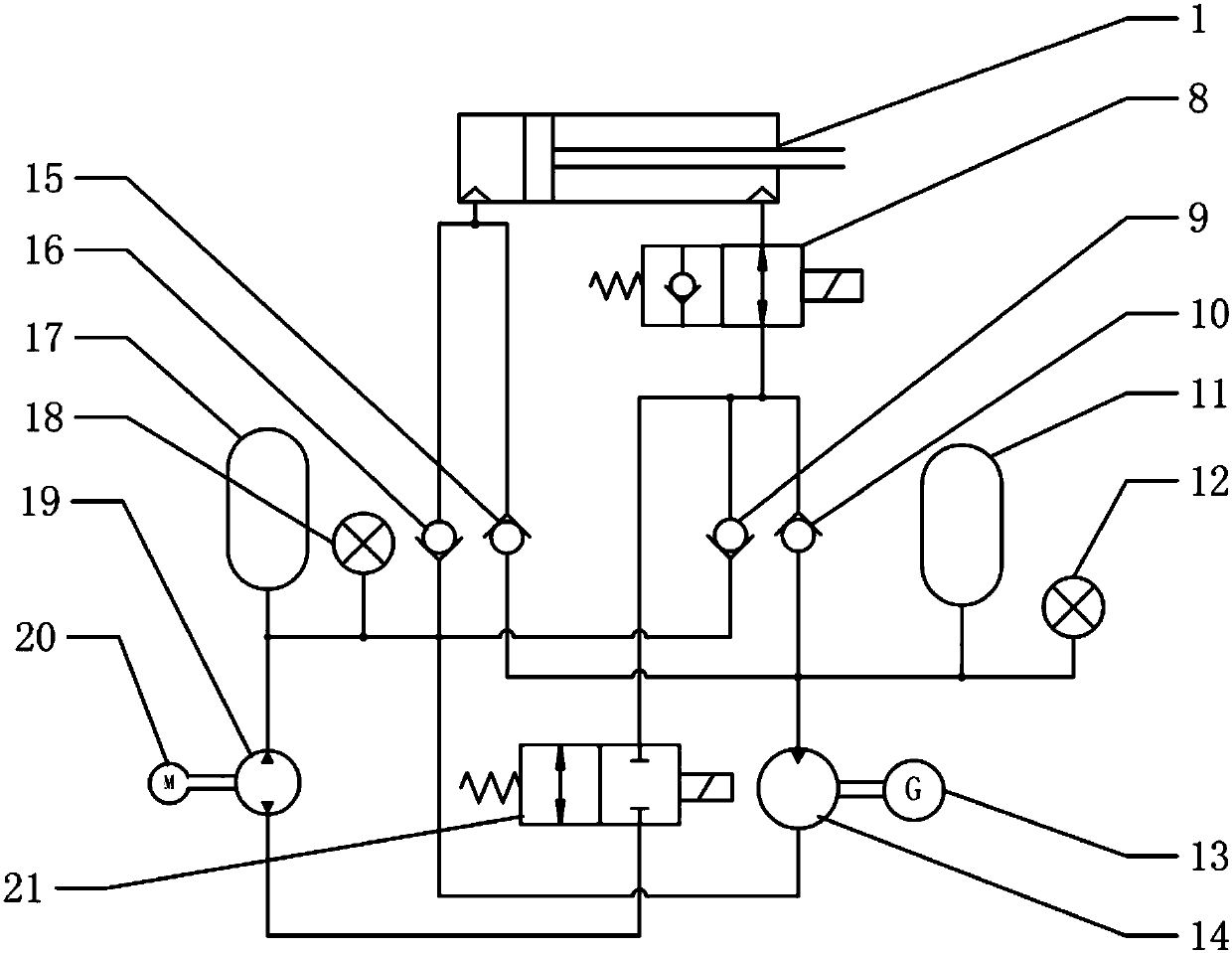

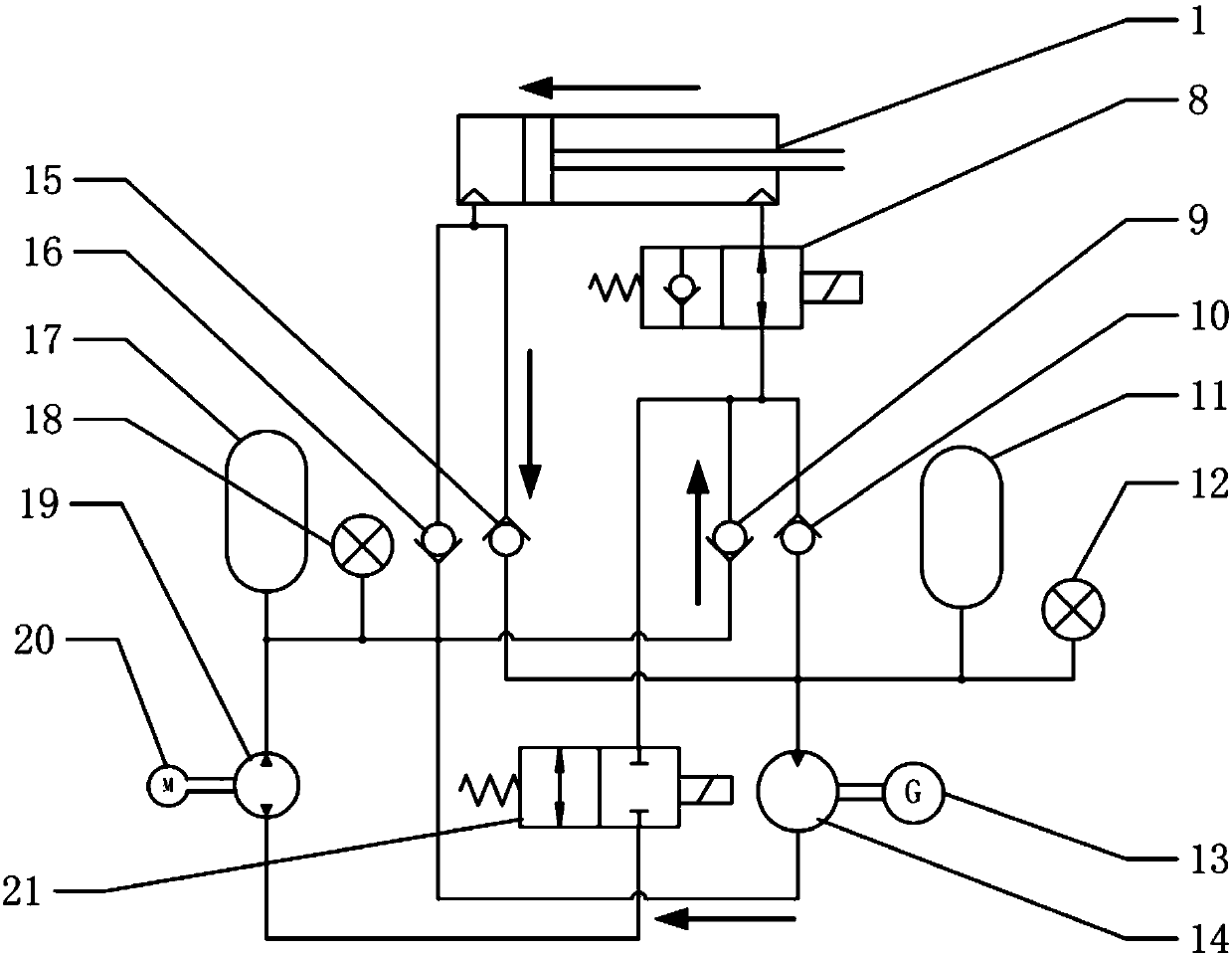

[0027] Such as figure 1 As shown, the present invention includes a floating body structure floating on the sea surface and a hydraulic system connected to the floating body structure for energy conversion. The connecting rod 2 between the two synchronous pulleys; the floating body 5 is a sealed structure welded by internal hollow steel, the floating body 5 is hinged with the bracket 4, and the bracket 4 is a frame fixed on the shore or the seabed or one side of a large floating body The structure plays a supporting role for the whole system, so that the floating body 5 swings around the fulcrum on the support with the ups and downs of the waves; the connecting rod 2 is connected with the hydraulic system, and converts the mechanical energy of the floating body 5 into hydraulic energy and transmits it to the hydraulic system for power generation....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com