Magnetic Particle Driven Vibration Absorption System

A technology of magnetic particles and vibration absorbers, which is applied in the direction of magnetic springs, vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the problems of corresponding adjustment of the most frequency of the vibration absorber, and achieve the effect of simple assembly and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

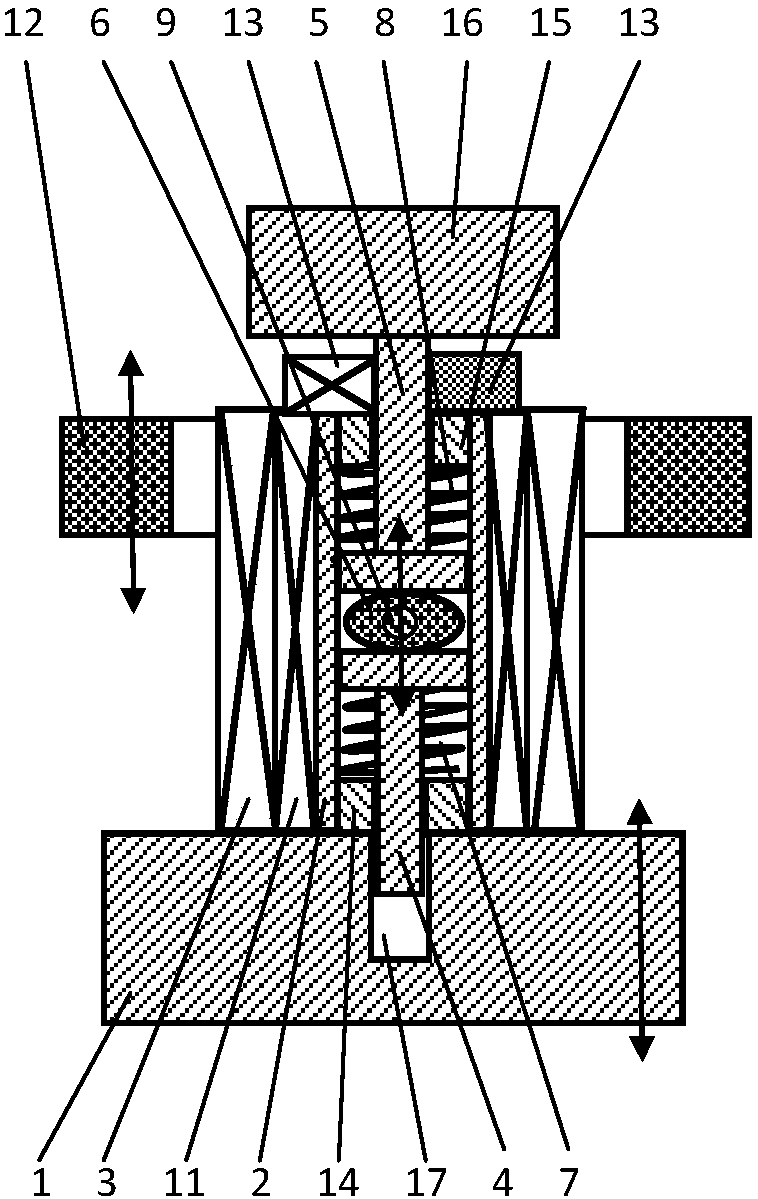

[0056] Such as figure 1 As shown, a magnetic particle-driven vibration-absorbing system provided according to the present invention includes a vibration isolation platform 1, a guide mechanism 2, an excitation coil 3, a first telescopic rod 4, a second telescopic rod 5, rotating magnetic particles 6, a first spring 7. The second spring 8; the guide mechanism 2 and the excitation coil 3 are fastened to the vibration isolation platform 1; the first telescopic rod 4 and the second telescopic rod 5 can slide along the guide mechanism 2; the first telescopic rod 4 and the second telescopic rod Rotating magnetic particles 6 are arranged between the opposite ends of the two telescopic rods 5; one end of the first spring 7 is connected to the first telescopic rod 4, and the other end of the first spring 7 is relatively fixed with the vibration isolation platform 1; one end of the second spring 8 Connect the second telescopic rod 5, the other end of the second spring 8 is relatively fi...

no. 2 example

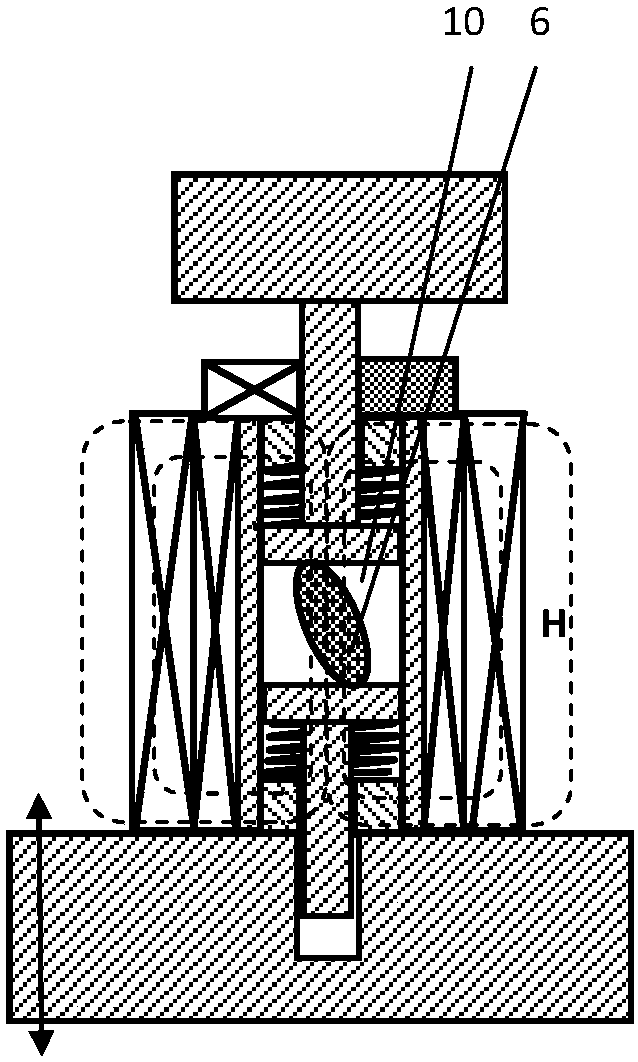

[0060] Such as figure 2 As shown, a magnetic particle-driven vibration-absorbing system provided according to the present invention includes a vibration isolation platform 1, a guide mechanism 2, an excitation coil 3, a first telescopic rod 4, a second telescopic rod 5, rotating magnetic particles 6, a first spring 7. The second spring 8; the guide mechanism 2 and the excitation coil 3 are fastened to the vibration isolation platform 1; the first telescopic rod 4 and the second telescopic rod 5 can slide along the guide mechanism 2; the first telescopic rod 4 and the second telescopic rod Rotating magnetic particles 6 are arranged between the opposite ends of the two telescopic rods 5; one end of the first spring 7 is connected to the first telescopic rod 4, and the other end of the first spring 7 is relatively fixed with the vibration isolation platform 1; one end of the second spring 8 Connect the second telescopic rod 5, the other end of the second spring 8 is relatively f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com