Device for measuring temperature in molten metal

A technology of molten metal and metal, which is applied in the field of long-term thermocouple equipment, can solve the problems of expensive and other problems, and achieve the effect of accurate temperature measurement, increased life expectancy, and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

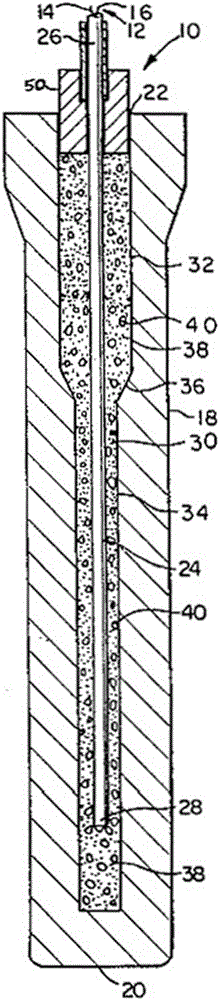

[0008] Referring to the drawings, wherein like reference numerals refer to like elements throughout, in figure 1 Among them, 10 represents the molten metal temperature measuring device according to the present invention.

[0009] Such as figure 1 Best shown, molten metal temperature measuring device 10 includes a thermocouple element, a portion of which is indicated generally at 12 . Typically, thermocouple element 12 consists of a positive element and a negative element (not shown). For the sake of discussion, in figure 1 In , the positive component is shown as positive lead 14 and the negative component is shown as negative lead 16 .

[0010] Positive lead wire 14 and negative lead wire 16 are generally composed of two different metal materials, such as platinum, platinum-rhodium alloy, nickel-chromium alloy, copper-nickel alloy, iron, nickel-aluminum alloy, and copper. Thermocouple element 12 is enclosed in a doublet (not shown) to isolate positive lead 14 from negative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com