Clamping device for clamping test piece and use method of clamping device

A technology of clamping device and clamping sheet, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of difficulty in controlling the dimensional accuracy of parts, reduced fatigue life, and large size of fatigue test pieces, so as to improve clamping stability The effect of high quality and accuracy, easy disassembly and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below with reference to the drawings and specific examples. For the convenience of discussion, "up", "down", "left", and "right" are used to indicate the position in each schematic diagram, which is conducive to the development of the discussion.

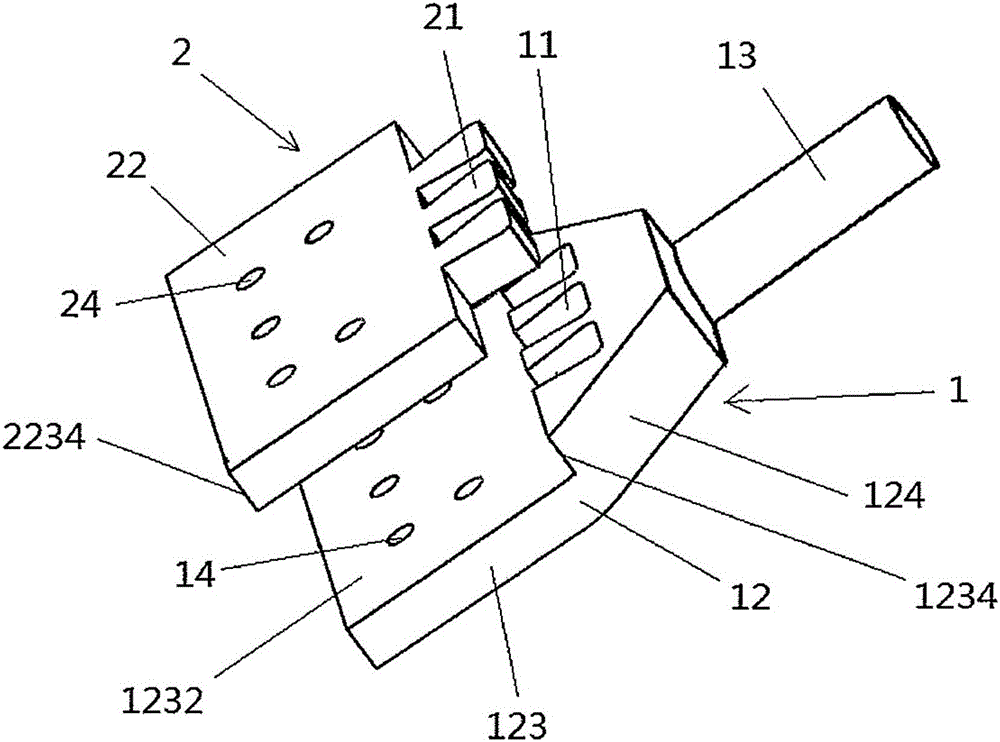

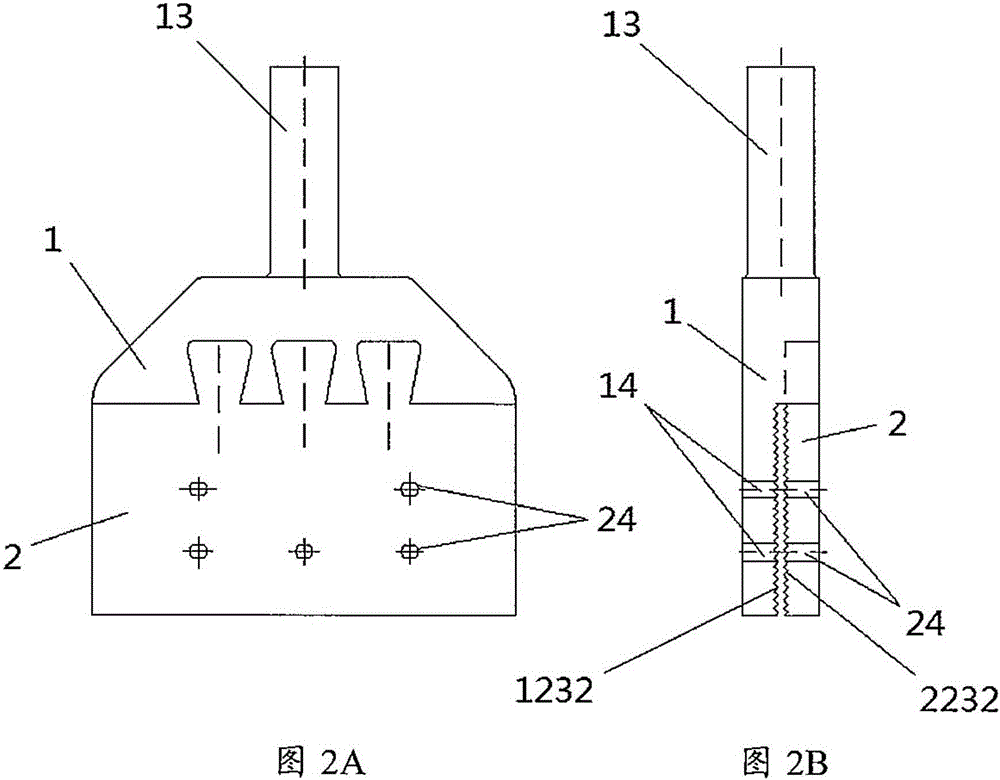

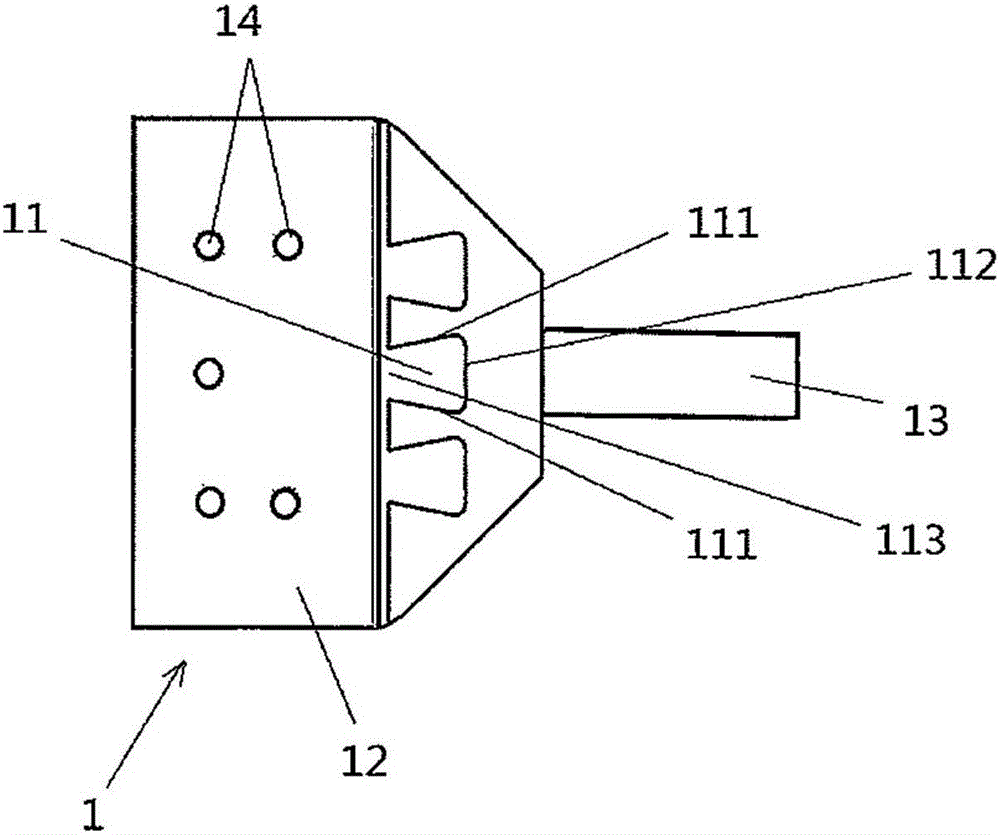

[0032] Such as figure 1 What is shown is the situation when the upper clamping piece 2 and the lower clamping piece 1 of the clamping device of the present invention are separated. Correspondingly, Figure 2A with Figure 2B This book is a front view and a side view when the upper clamping piece 2 and the lower clamping piece 1 of the clamping device of the present invention are combined. At the same time, you can refer to Figure 3A with Figure 3B , Respectively show the lower clamping piece 1 and the upper clamping piece 2 of the clamping device of the present invention.

[0033] in figure 1 Among them, the preferred clamping device of the present invention includes: an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com