Coil

A coil and coil support technology, applied in the direction of coil, direct mass flow meter, liquid/fluid solid measurement, etc., can solve the problems of damaging the coil wire, increasing, destroying the coil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

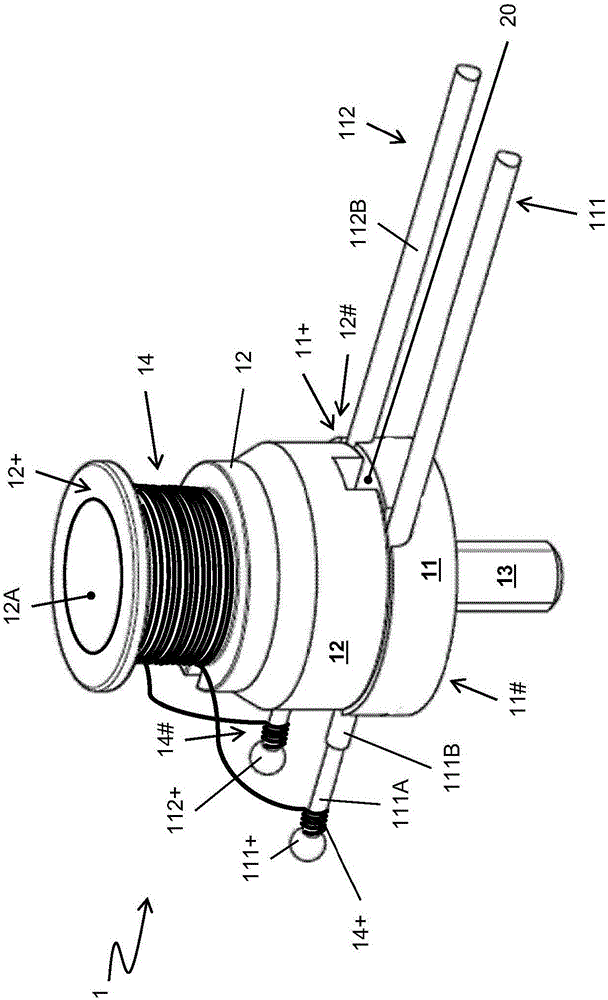

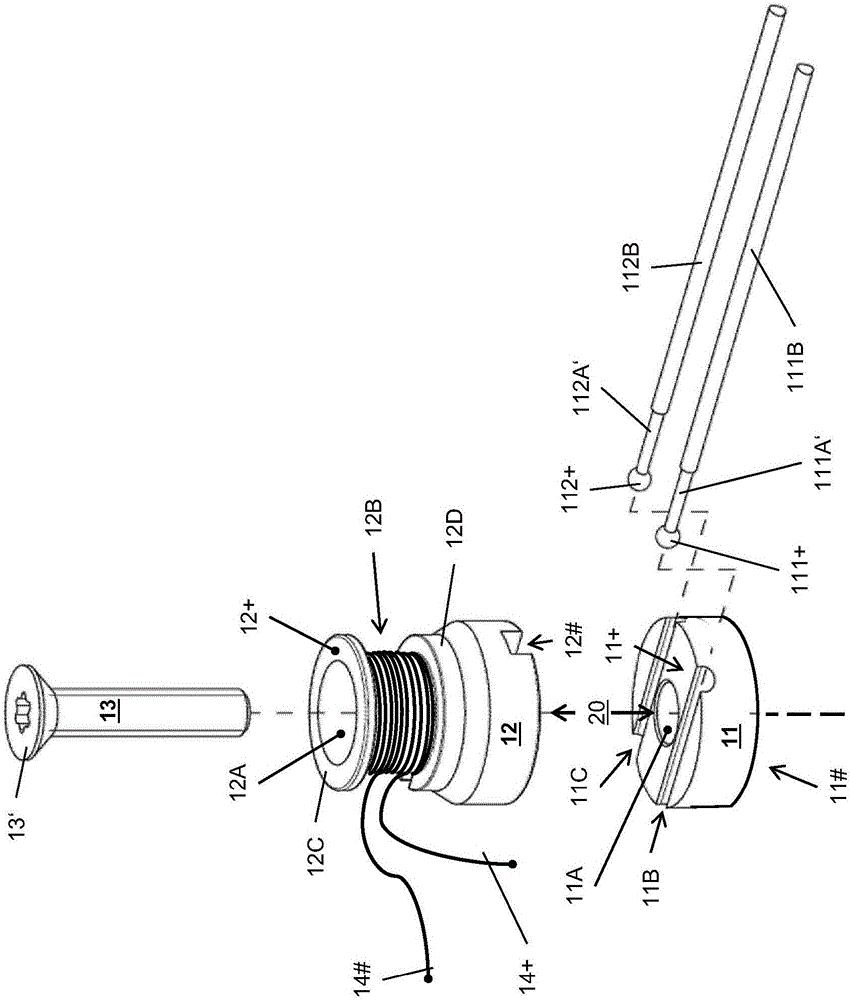

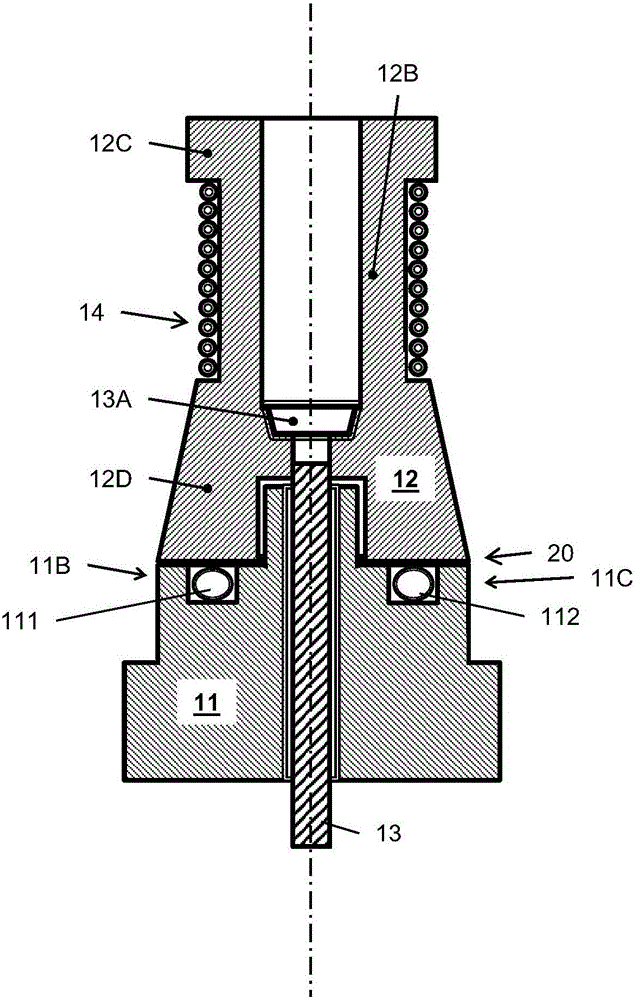

[0051] figure 1 , 2 Shown in and 3 are examples of embodiments of the coil 1 according to the invention, eg coils which can be used as part of vibratory measuring transducers, correspondingly electronic vibratory measuring devices formed from vibrating measuring transducers.

[0052] The coil 1 includes: a platform 11, the platform 11 has a first end 11+ formed by a first end face and a second end 11# away from the end 11+ and formed by a second end face, for example, a second end face parallel to the first end face; A coil support 12, the coil support 12 has a first end 12+ formed by a first end face and a second end 12# that is away from the end 12+ and is formed by a second end face, such as a second end face parallel to the first end face; and The coil supports a wound coil wire 14 of electrically conductive material, eg copper or a copper alloy or platinum or a platinum alloy. The platform 11 - here exemplified as a cylinder, respectively a disk - can be produced, for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com