Automatic test system with event detection capability

An automatic test system and event technology, applied in semiconductor/solid-state device test/measurement, transmission system, multi-carrier system, etc., can solve problems such as time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

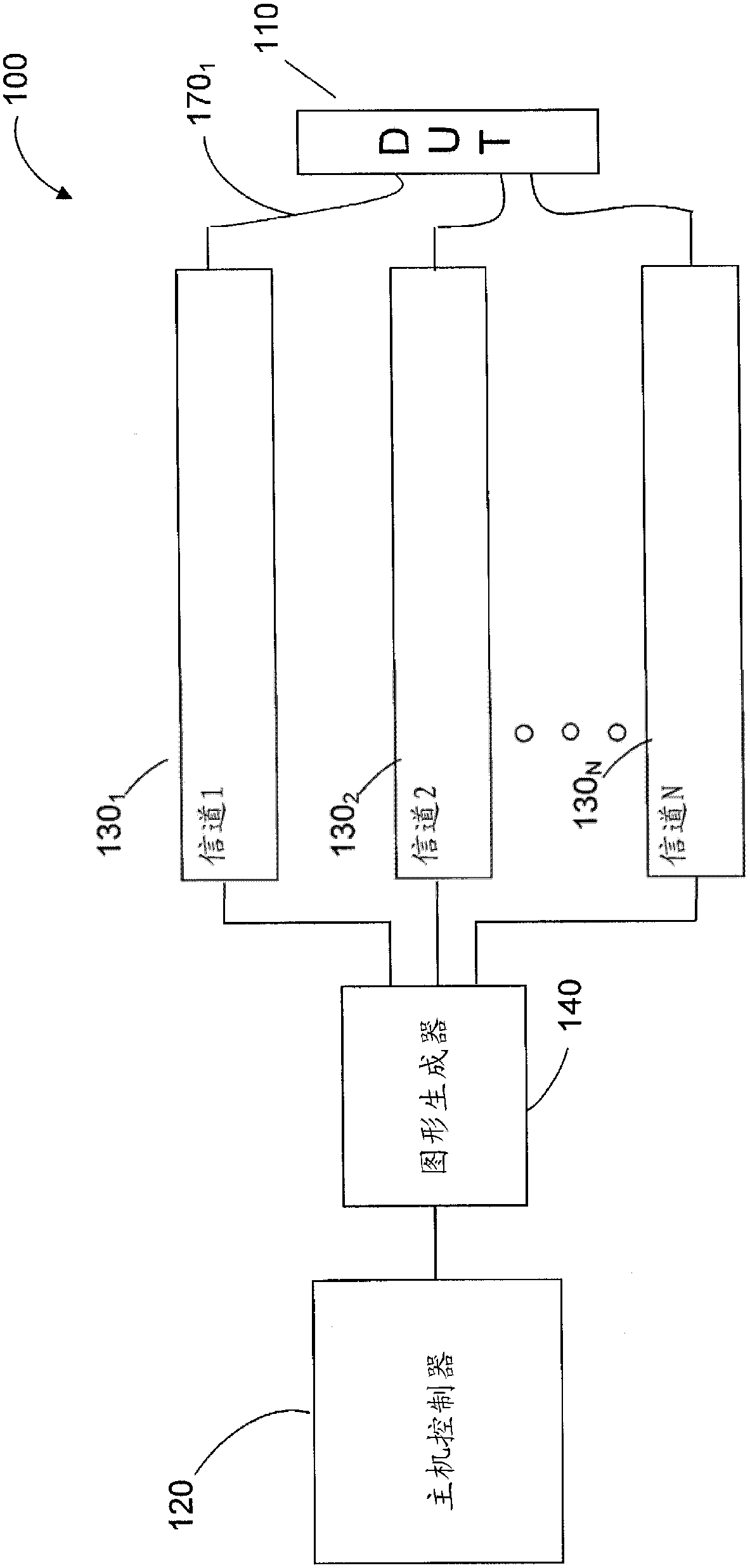

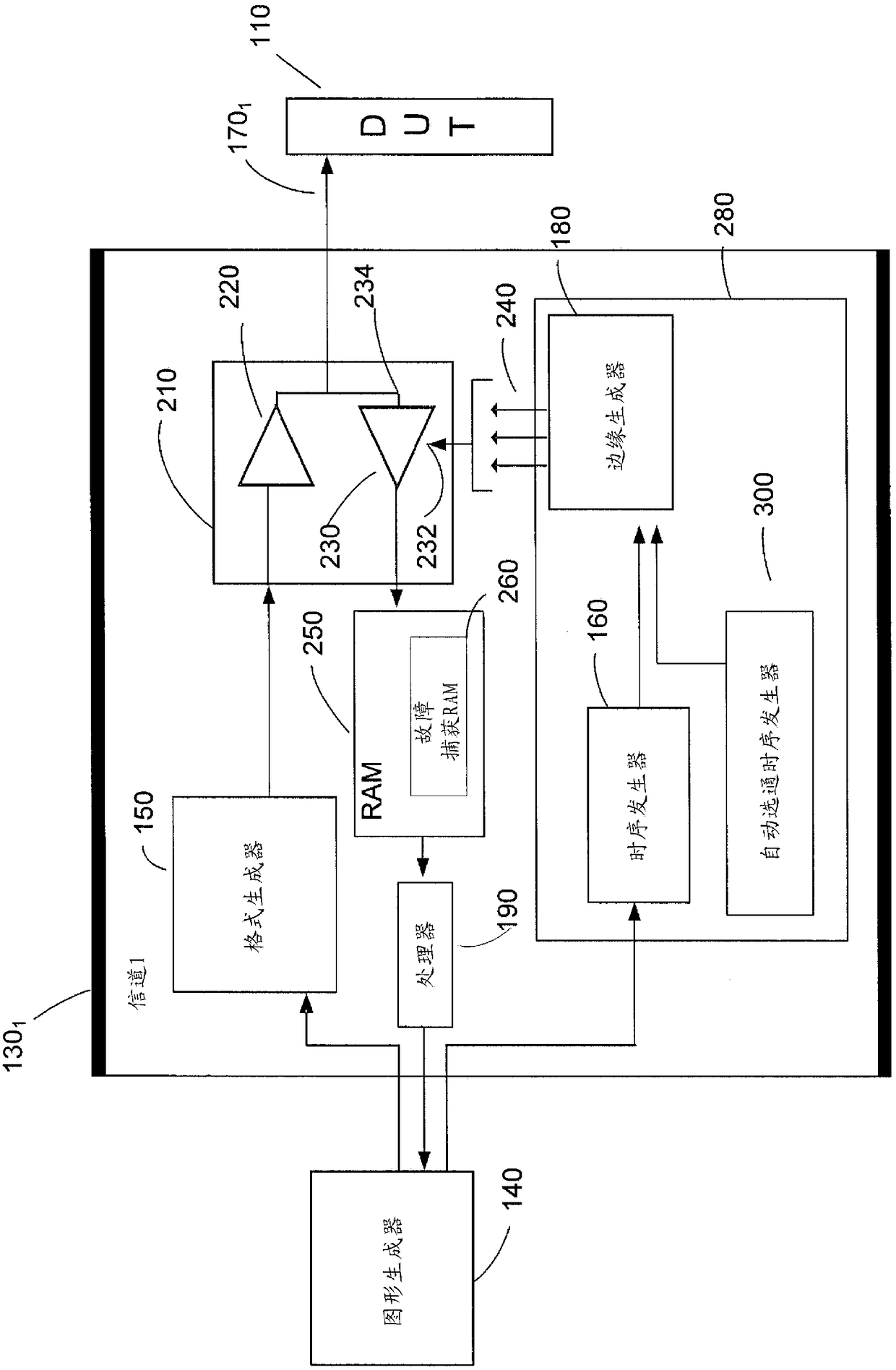

[0017] The present inventors have recognized and appreciated that an improved semiconductor device tester can reduce test development time and device test time. This improved test system enables new designs of semiconductor devices to be brought into production earlier by reducing test development time. By reducing device testing time, greater throughput in the manufacture of semiconductor devices can be achieved. Therefore, improved testers that can program faster and perform shorter tests can enhance the economics of developing semiconductor devices.

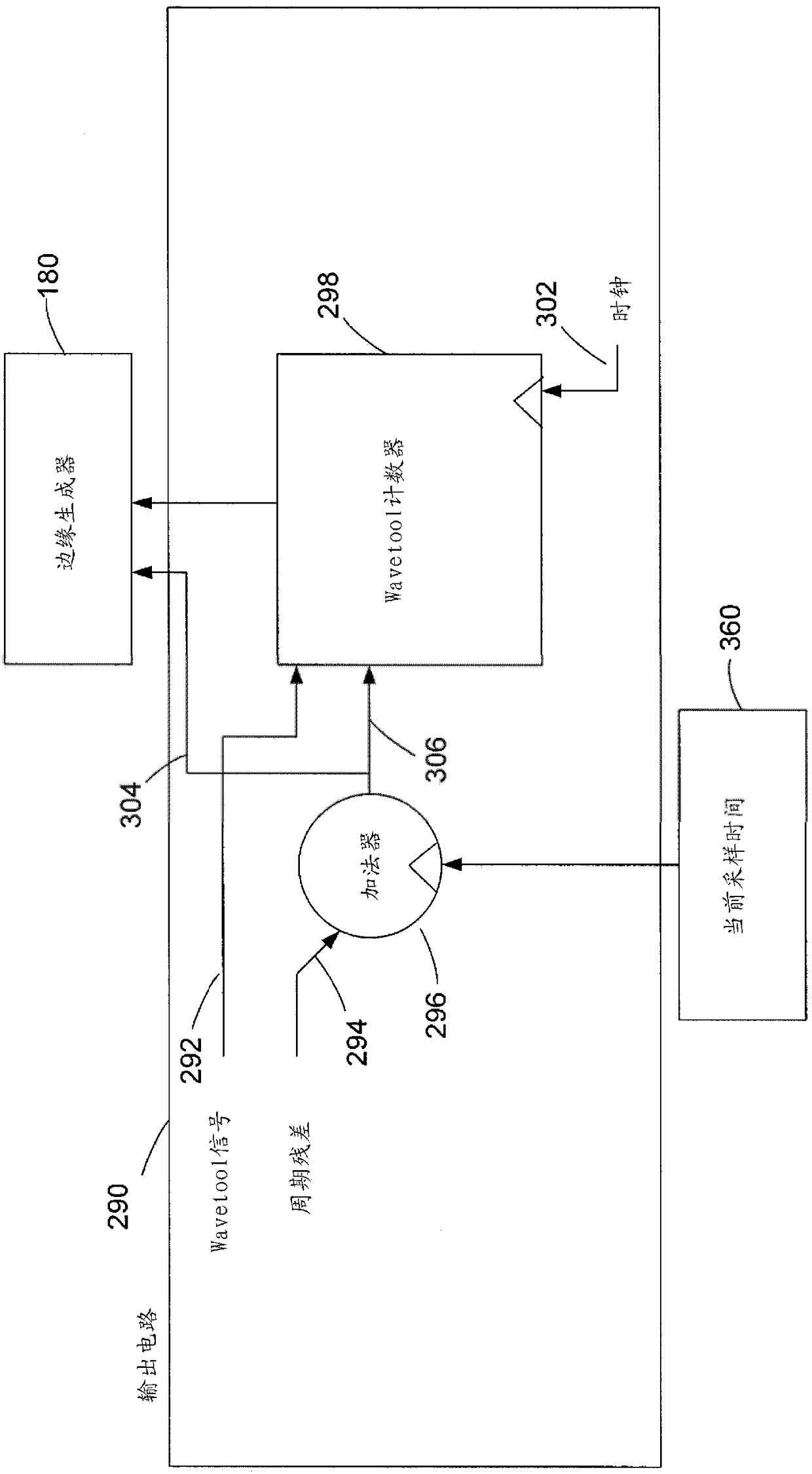

[0018] This enhanced value can be realized using a tester designed to provide a programmable method to detect the timing of signal transitions in the DUT output. Such a tester can be easily programmed by a test engineer. Alternatively or in addition, the tester can reduce the time required to run a test by accepting, as part of the programming that defines the test, a window within one repetition of the repetitive signal in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com