Personalized femoral prosthesis and manufacturing method

A technology of femoral prosthesis and manufacturing method, which is applied in the field of personalized femoral prosthesis and manufacturing, can solve the problems of low design efficiency, difficult molding, easy loosening, etc., and achieve the effect of improving design efficiency and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

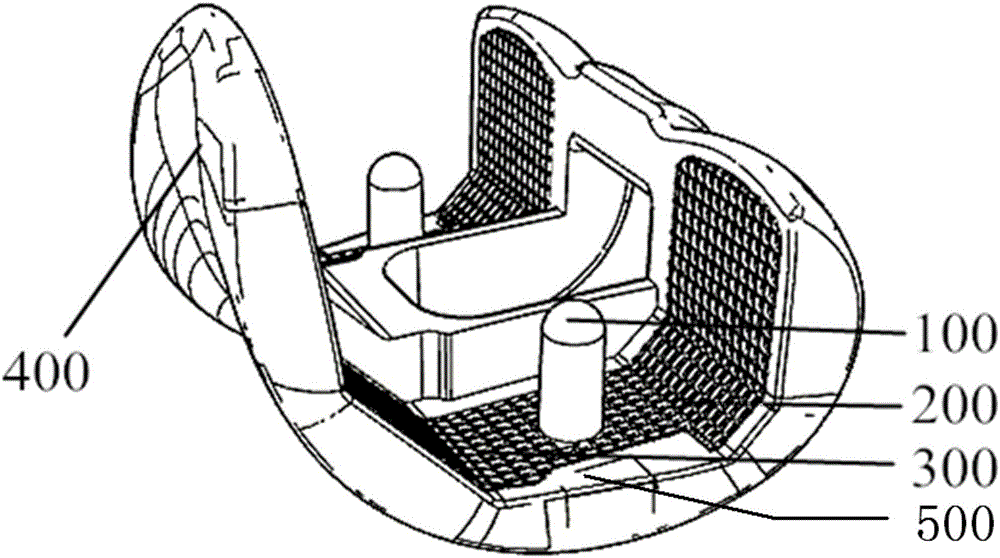

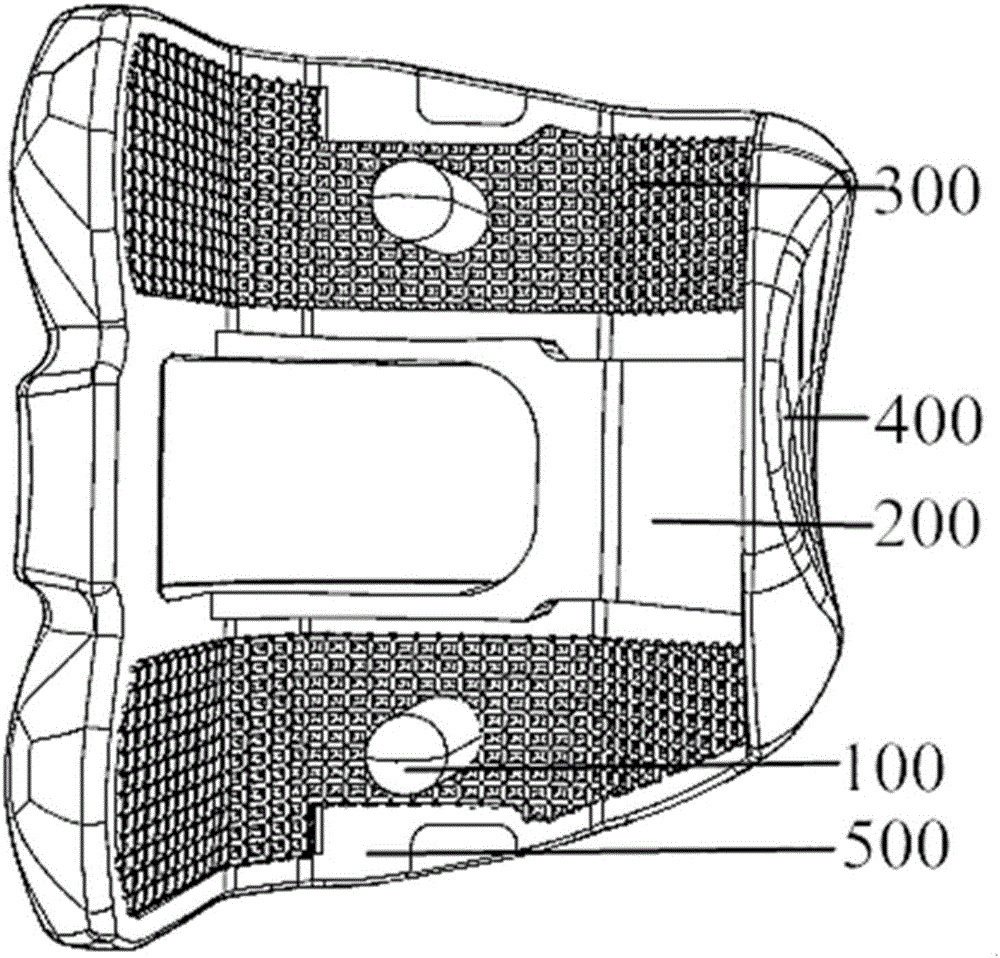

[0035] like Figures 1 to 4 shown. The invention discloses a personalized femoral prosthesis. The femoral prosthesis structure includes: a patella articular surface prosthesis 400 and a femoral articular surface prosthesis 200 inside the articular surface prosthesis 400; the femoral articular surface prosthesis 200 is provided with two A symmetrical femoral condyle prosthesis 100;

[0036] On the middle surface of the femoral articular surface prosthesis 200 , the truss porous structure prosthesis 300 is distributed in an array; on both sides of the femoral articular surface prosthesis 200 there are femoral platform prosthesis 500 .

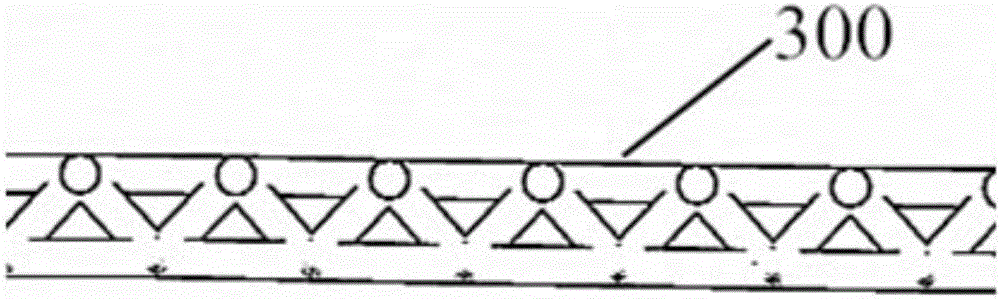

[0037] In order to achieve good biocompatibility of the biofixed femoral prosthesis and prevent the prosthesis from loosening, the truss porous structure prosthesis 300 has multiple layers, and the pores in each layer are gradient pores, and the pore diameter gradually increases from inside to outside. That is, the diameter of the holes near th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com