Paint spraying, airing and stacking integrated machine for C steels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

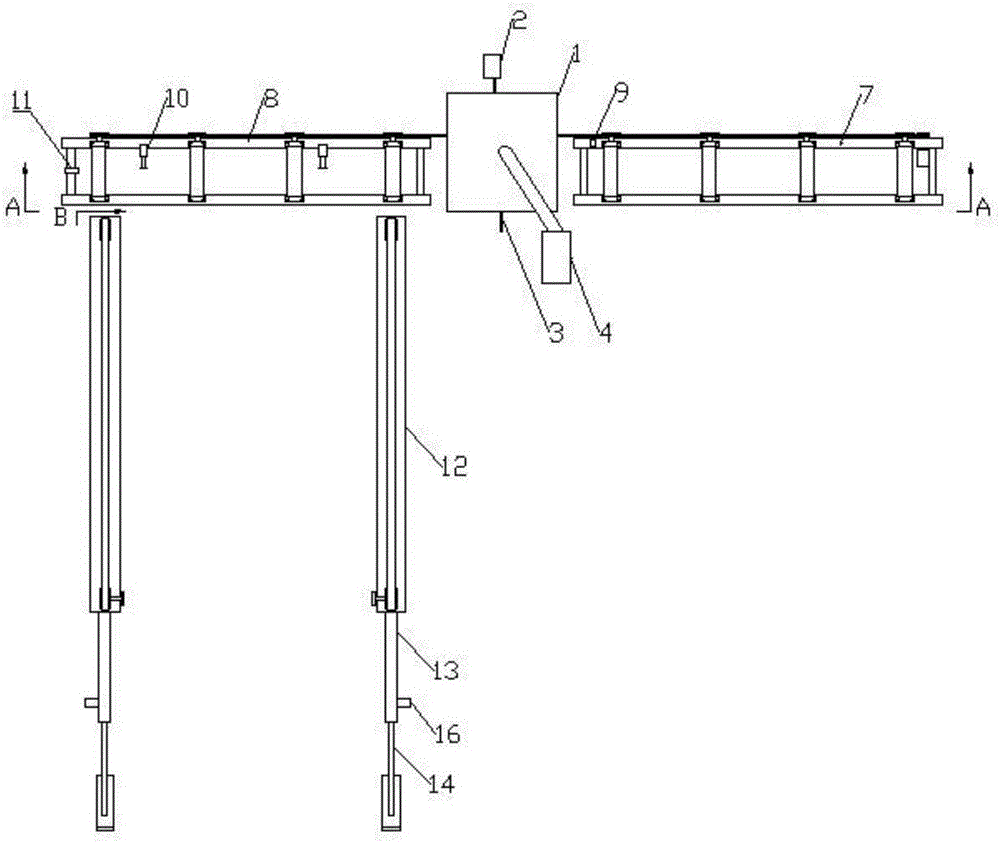

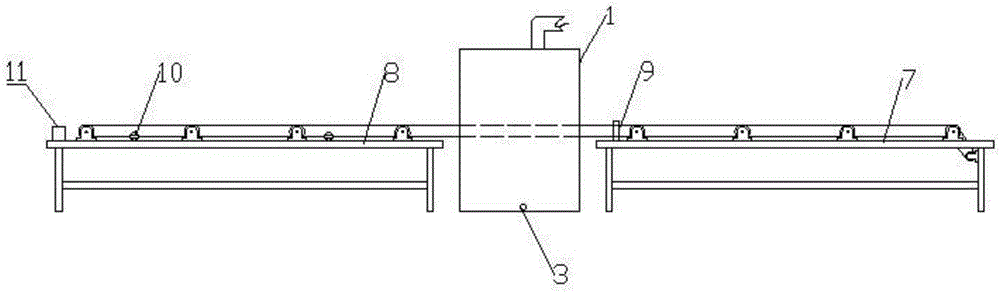

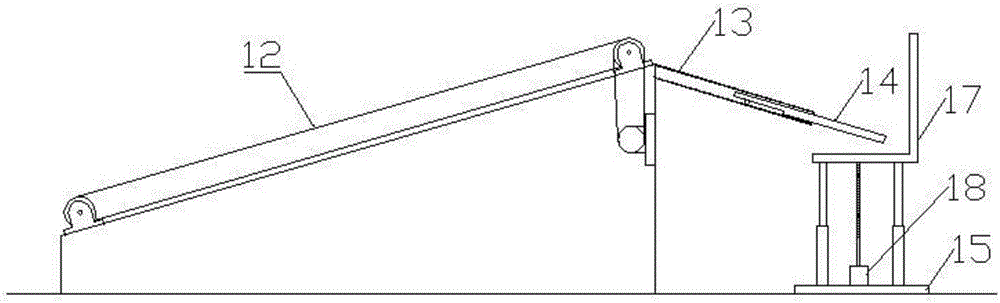

[0021] As shown in the figure, a C-shaped steel painting, drying, and stacking integrated machine includes a paint spraying machine. A plurality of nozzles connected to the spraying machine 2 constitutes; the inner bottom of the spray booth 1 is funnel-shaped, and a drain pipe 3 is arranged at the bottom of the spray booth 1, and an air cleaning device 4 is arranged on one side of the spray booth 1. The suction port of the air cleaning device 4 is connected to the inner top of the spray booth 1 through a pipeline, and the nozzle is composed of a double-head nozzle 5 arranged horizontally in the center of the spray booth 1, a plurality of which are arranged on the inner wall of the spray booth 1 and respectively A single-head nozzle 6 pointing to the center of the spray booth 1 is formed; a roller feed conveyor 7 is set at the feed end of the paint spray booth 1, a roller discharge conveyor 8 is set at the discharge end of the paint spray booth 1, and the roller feed The materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com